Rock drilling device for drill jambo

A technology for a rock drilling device and a rock drilling rig is applied in the directions of supporting devices, drilling equipment, drilling equipment and methods, etc., which can solve the problems of small working range and the like, and achieve a wide working range, strong shock resistance and strong mobility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the accompanying drawings.

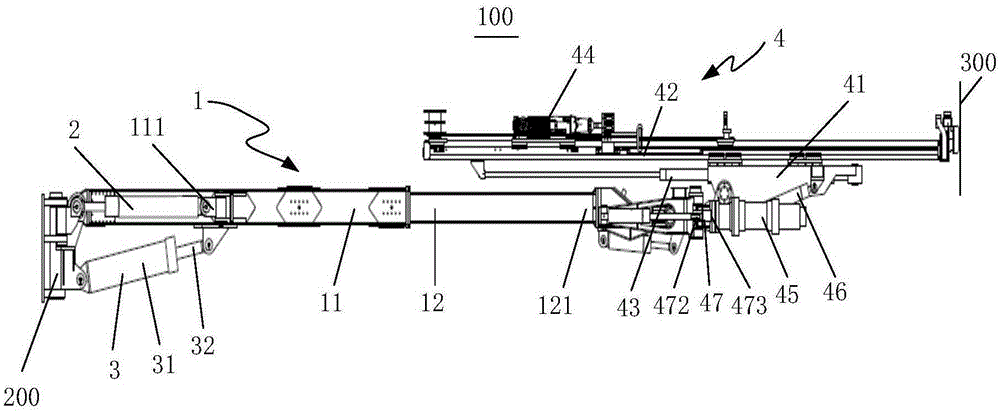

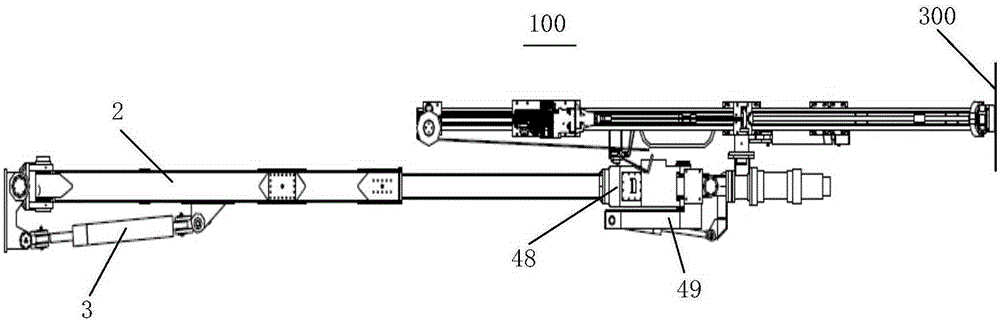

[0024] like figure 1 shown, figure 1 The rock drilling apparatus 100 is schematically shown including a rock drilling arm assembly 1 , a yaw hydraulic cylinder 2 , a pitch hydraulic cylinder 3 and a rock drilling mechanism 4 .

[0025] In the embodiment of the present application, the rock drilling arm assembly 1 is a telescopic structure, which is driven by a hydraulic cylinder (not shown in the figure) to realize the elongation and shortening of the rock drilling arm assembly 1 .

[0026] The deflection hydraulic cylinder 2 is hinged with the deflection end 111 of the rock drilling arm assembly 1 to actuate the rock drilling arm assembly 1 to perform a deflection movement. With this structure, the rock drilling arm assembly 1 can be flexibly adjusted to deflect leftward or rightward relative to its geometric centerline, thereby expanding the working range of the rock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com