Wearable flexible stress sensor and preparation method and application thereof

A stress sensor, flexible technology, applied in applications, instruments, measuring force, etc., can solve problems such as troublesome steps, pollution, and high consumption, and achieve the effects of easy detection, high sensitivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

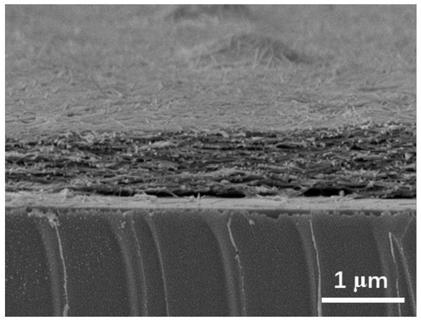

[0062] (1) Weigh 0.2g of graphene oxide with a sheet size of about 1-2µm prepared by a chemical method (improved Hummers method) and place it in a beaker, add 100ml of deionized water, and ultrasonically (power 700W) for 30 minutes to obtain 2mg / ml Graphene oxide dispersion, with 1mol / L NaHCO 3 The solution adjusts the pH value of the graphene oxide dispersion to 6.5. Weigh 0.1 g of dopamine into a beaker, add 10 mL of buffer (trishydroxymethylaminomethane), and stir for 5 minutes to obtain a 10 mg / mL polydopamine aqueous solution. Take 10 mL of graphene oxide dispersion and mix with 0.14 mL of polydopamine aqueous solution, and stir for 24 hours. Take 0.26g of nickel chloride into 100mL of deionized water, and stir evenly. Take 0.054mL nickel chloride aqueous solution in the mixture, stir for 4 hours.

[0063] (2) Weigh 8mL silver nanowire (length 5µm, diameter 30-40nm) dispersion (10 mg / ml) into the reagent bottle, add 5mL graphene oxide, dopamine and nickel chloride mixe...

Embodiment 2

[0068] (1) Weigh 0.2g of MXene(Ti 3 C 2 X) Place in a beaker, add 100ml of deionized water, and sonicate for 30 minutes to obtain a 2mg / ml Mxene dispersion. Weigh 0.1 g of dopamine into a beaker, add 10 mL of buffer solution, and stir for 5 minutes to obtain a 10 mg / mL polydopamine aqueous solution. Take 10 mL of graphene oxide dispersion and mix with 0.14 mL of polydopamine aqueous solution, and stir for 24 hours. Take 0.26g of nickel chloride into 100mL of deionized water, and stir evenly. Take 0.054mL nickel chloride aqueous solution in the mixture, stir for 4 hours.

[0069] (2) Weigh 8mL silver nanowire (length 5µm, diameter 30-40nm) dispersion (10 mg / ml) into the reagent bottle, add 5mL Mxene(Ti 3 C 2 X) Mix the solution with dopamine and nickel chloride, and redisperse it by ultrasonic vibration treatment. Suction filter with a microporous membrane, wash with deionized water several times, and suck off the supernatant to obtain a uniform dispersion containing silv...

Embodiment 3

[0074]1) Weigh 0.2g of graphene oxide with a sheet size of about 1-2µm prepared by a chemical method and place it in a beaker, add 100ml of deionized water, and ultrasonicate for 30 minutes to obtain a 2mg / ml graphene oxide dispersion. Weigh 0.1 g of dopamine into a beaker, add 10 mL of buffer solution, and stir for 5 minutes to obtain a 10 mg / mL polydopamine aqueous solution. Take 10 mL of graphene oxide dispersion and mix with 0.14 mL of polydopamine aqueous solution, and stir for 24 hours. Take 0.26g of calcium chloride into 100mL of deionized water, and stir evenly. Take 0.054mL nickel chloride aqueous solution in the mixture, stir for 4 hours.

[0075] (2) Weigh 8mL copper nanowire (5µm in length, 30-40nm in diameter) dispersion (10 mg / ml) into a reagent bottle, add 5mL of Yanniplan graphene, dopamine and nickel chloride obtained in step (1) Mix the solution and sonicate it to redisperse it. Suction filter with a microporous membrane, wash with deionized water several ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com