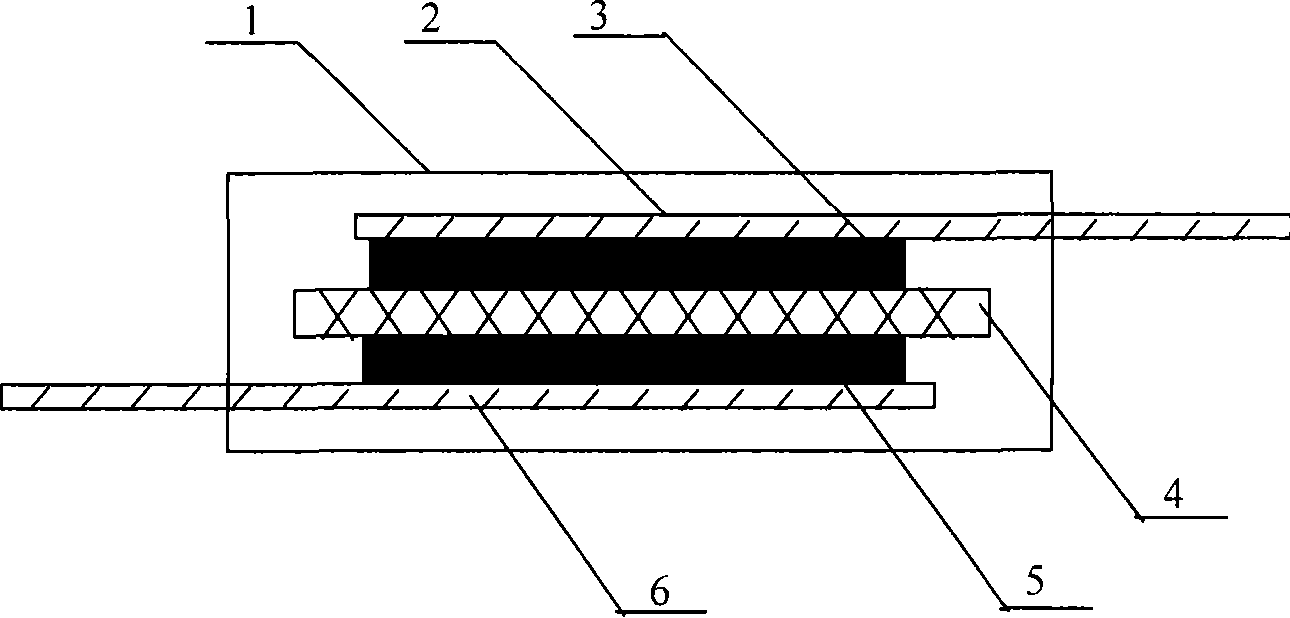

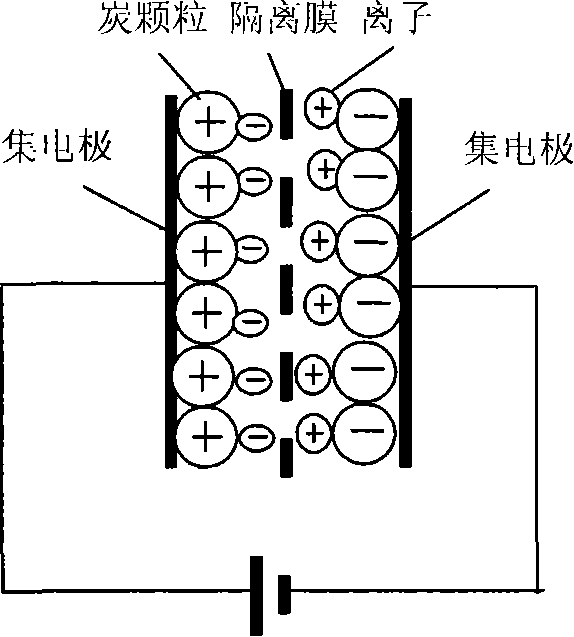

Flexible thin film type solid-state super capacitor and its manufacture process

A supercapacitor, flexible film technology, applied in the field of capacitors, can solve the problems of high packaging requirements, low production efficiency, large volume, etc., and achieve the effect of good power characteristics and low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of electrode slurry: Stir and mix 80 g of activated carbon, 10 g of carbon black, 10 g of polyvinylidene fluoride (PVDF) and 500 g of N-methylpyrrolidone for 3 hours.

[0033] (2) Preparation of electrolyte slurry: Mix 100g of polyvinyl alcohol powder (PVA) with 800g of deionized water, heat to 95°C and stir for 2 hours, then add 1g of SiO with a particle size of 2 The fine powder and 15 g of tetraethylammonium tetrafluoroborate were stirred for 10 hours and mixed uniformly.

[0034] (3) Preparation of external electrode slurry: Mix 10g of polyvinyl alcohol powder (PVA) with 100g of deionized water, heat to 90°C and stir for 1 hour, then add 20g of nickel powder (-200 mesh) and 10g of silver powder (-200 mesh), stirred for 2 hours.

[0035] (4) Preparation of encapsulation slurry: Stir and mix 50 g of polyvinylidene fluoride (PVDF) and 500 g of deionized water for 3 hours.

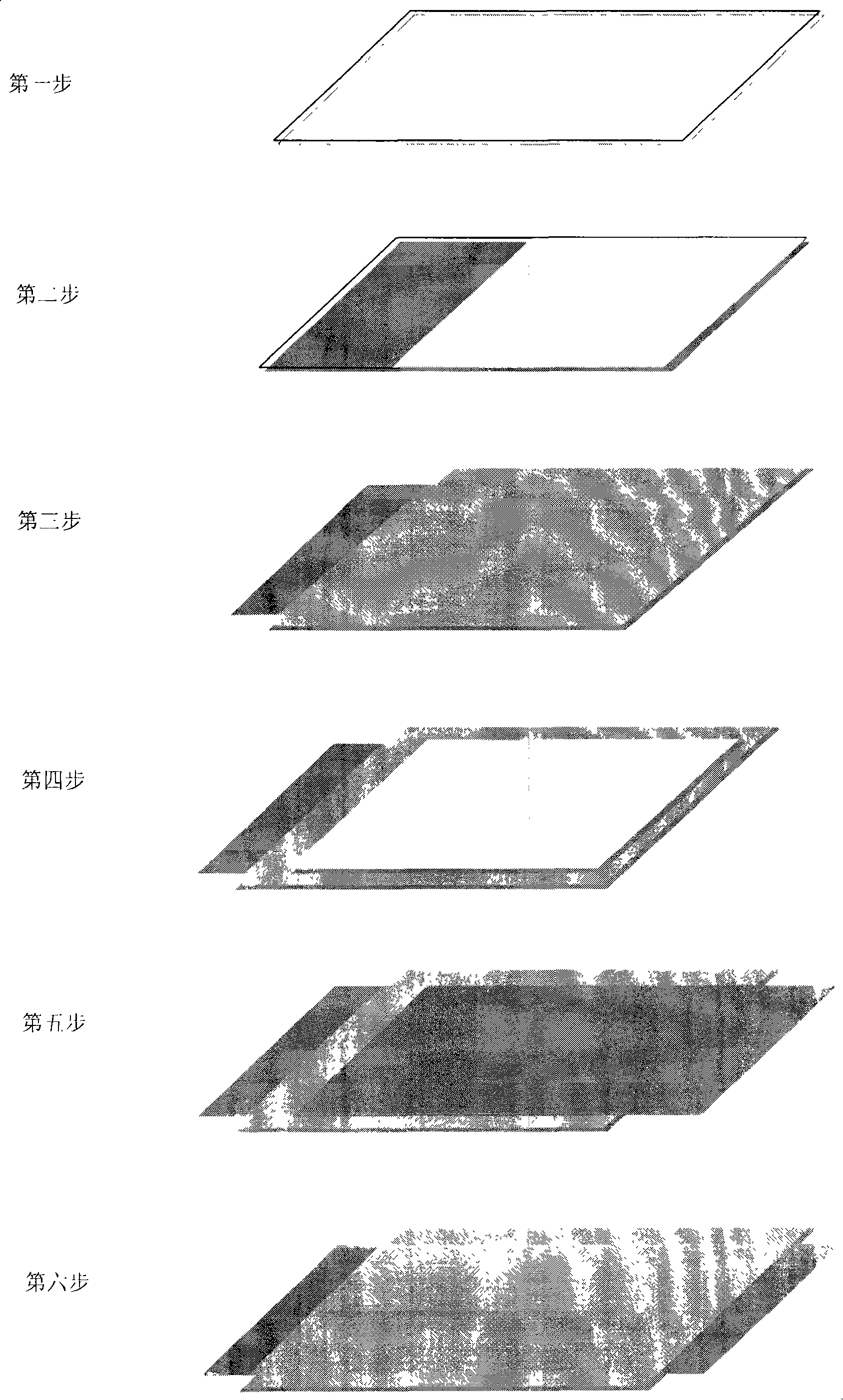

[0036] (5) Prepare printing templates for printing the outer electrode film, el...

Embodiment 2

[0044] (1) Electrode slurry preparation: 60 g of activated carbon, 25 g of manganese dioxide, 5 g of carbon black, 10 g of polyvinylidene fluoride (PVDF) and 500 g of N-methylpyrrolidone were stirred and mixed for 3 hours.

[0045] (2) Preparation of electrolyte slurry: mix 100g of polyvinyl alcohol powder (PVA) with 800g of deionized water, heat to 95°C and stir for 2 hours, then add 1g of SiO2 micropowder with a particle size of <5μm, and 15g of tetraethylammonium tetrafluoroborate , and stirred for 10 hours to mix well.

[0046] (3) Preparation of external electrode slurry: Heat 10g of polyvinylidene fluoride powder (PVDF) and 100g of N-methylpyrrolidone to 60°C and stir for 1 hour, then add 20g of nickel powder (-200 mesh) and 10g of silver powder (-200 mesh), stirred for 2 hours.

[0047] (4) Preparation of encapsulation slurry: Stir and mix 50 g of polyvinylidene fluoride (PVDF) and 500 g of deionized water for 3 hours.

[0048] (5) According to the process steps of Ex...

Embodiment 3

[0050] (1) Electrode slurry preparation: 85g of polypyrrole (PPy), 5g of carbon black, 10g of polyvinylidene fluoride (PVDF) and 500g of N-methylpyrrolidone were stirred and mixed for 3 hours.

[0051] (2) Electrolyte slurry preparation: mix 100g copolymer P (VDF-HFP) with 800g NMP, stir for 2 hours, add 30ml dibutyl phthalate (DBP), stir for 1 hour, then add 0.3g Al 2 o 3 Nano powder (average particle diameter<60nm), 15g tetraethylammonium tetrafluoroborate, stirred for 1 hour and mixed evenly.

[0052] (3) Preparation of external electrode slurry: Heat 10g of polyvinylidene fluoride powder (PVDF) and 100g of N-methylpyrrolidone to 60°C and stir for 1 hour, then add 20g of nickel powder (-200 days) and 10 grams of silver powder (-200 mesh), stirred for 2 hours.

[0053] (4) Preparation of encapsulation slurry: Stir and mix 50 g of polyvinylidene fluoride (PVDF) and 500 g of deionized water for 3 hours.

[0054] (5) According to the process steps of Example 1, the external ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com