In-situ method for preparing graphene/carbon nanotube composite film

A carbon nanotube composite and in-situ preparation technology, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems that the horizontal composite structure cannot be grown in situ, and the characteristics cannot be fully and effectively exerted. To achieve the effect of thickness controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

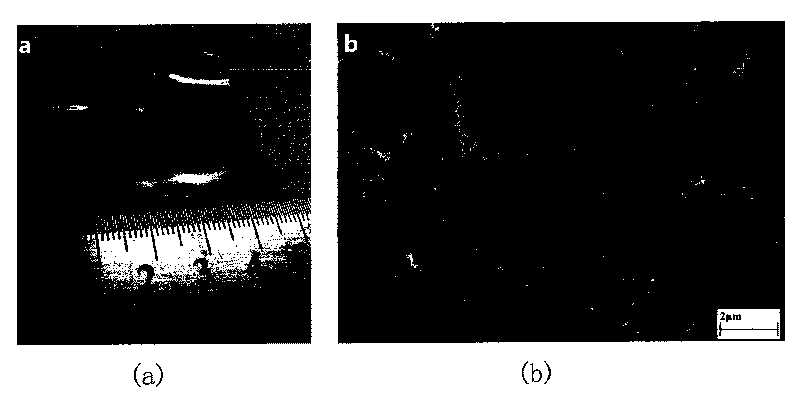

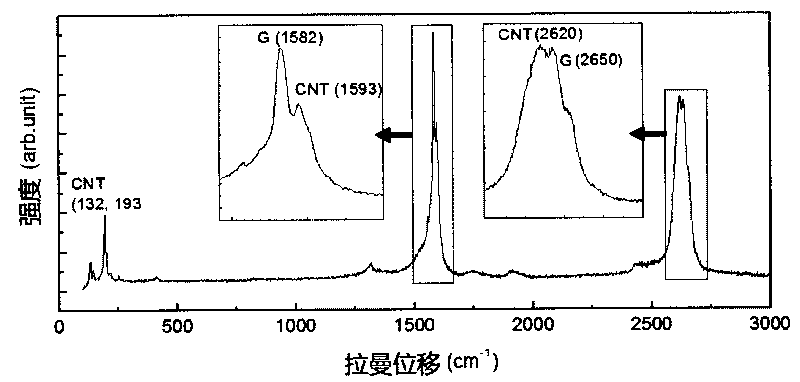

[0019] This embodiment includes the following steps:

[0020] 1. Weigh ferrocene and sulfur with a mass ratio of 58:1, mix them evenly, and place them at the front of the reactor. The purity is 99.5%, the thickness is 0.1mm, and the area is 4×4cm 2 The polycrystalline nickel sheet is placed in the center of the reactor to seal the reactor;

[0021] 2. Inject hydrogen / argon mixed gas with a flow rate of 100 / 200mL / min into the reactor, at the same time raise the temperature of the center of the reactor to 1150°C, and adjust the flow rate of hydrogen / argon to 200 / 1000mL / min;

[0022] 3. Heat the ferrocene and sulfur at the front end of the reactor to 100°C to make them volatilize. The volatile gas is loaded into the reactor from the hydrogen / argon mixed gas adjusted in step 2. Stop heating the ferrocene and sulfur after 10 minutes of reaction. sulfur;

[0023] 4. Stop heating at the center of the reactor, turn off the hydrogen, adjust the flow of argon to 100mL / min, pull out th...

Embodiment 2

[0026] This embodiment includes the following steps:

[0027] 1. Weigh ferrocene and sulfur with a mass ratio of 78:1, mix them evenly, and place them at the front of the reactor. The purity is 99.5%, the thickness is 0.1mm, and the area is 2×2cm 2 cm 2 The polycrystalline nickel sheet is placed in the center of the reactor to seal the reactor;

[0028] 2. Inject hydrogen / argon mixed gas with a flow rate of 150 / 300mL / min into the reactor, and at the same time raise the temperature of the center of the reactor to 1100°C, and adjust the flow rate of hydrogen / argon to 100 / 800mL / min;

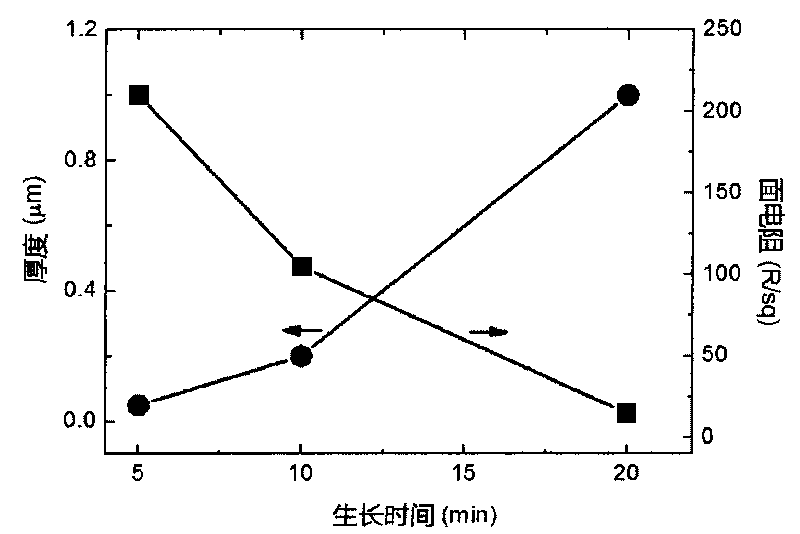

[0029] 3. Heat the ferrocene and sulfur at the front end of the reactor to 90°C to volatilize. The volatile gas is loaded into the reactor from the hydrogen / argon gas mixture adjusted in step 2. Stop heating the ferrocene / sulfur after 5 minutes of reaction ;

[0030]4. Stop heating at the center of the reactor, turn off the hydrogen, adjust the flow of argon to 150mL / min, pull out the nickel shee...

Embodiment 3

[0032] This embodiment includes the following steps:

[0033] 1. Weigh ferrocene and sulfur with a mass ratio of 78:1, mix them evenly, and place them at the front of the reactor. The purity is 99.5%, the thickness is 0.1mm, and the area is 2×2cm 2 cm 2 The polycrystalline nickel sheet is placed in the center of the reactor to seal the reactor;

[0034] 2. Inject hydrogen / argon mixed gas with a flow rate of 150 / 300mL / min into the reactor, and at the same time raise the temperature of the center of the reactor to 1100°C, and adjust the flow rate of hydrogen / argon to 100 / 800mL / min;

[0035] 3. Heat the ferrocene and sulfur at the front end of the reactor to 90°C to make them volatilize. The volatile gas is loaded into the reactor from the hydrogen / argon mixture adjusted in step 2, and stop heating the ferrocene / sulfur after 10 minutes of reaction ;

[0036] 4. Stop heating at the center of the reactor, turn off the hydrogen, adjust the flow of argon to 150mL / min, pull out the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com