Thermocouple insulation locator, mounting method thereof and wall temperature measuring device

A thermocouple and positioner technology, applied in the direction of measuring device, using electric device, measuring heat, etc., can solve the problems of thermocouple wire fatigue fracture, wire disconnection, shortening the service life of thermocouple, etc. Sensitive, mass-manufacturable, simple-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

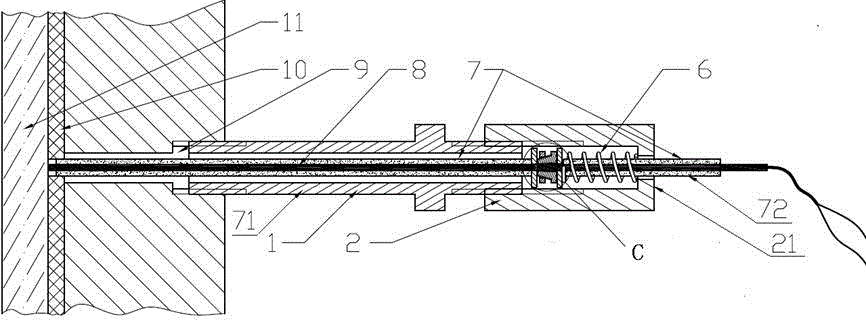

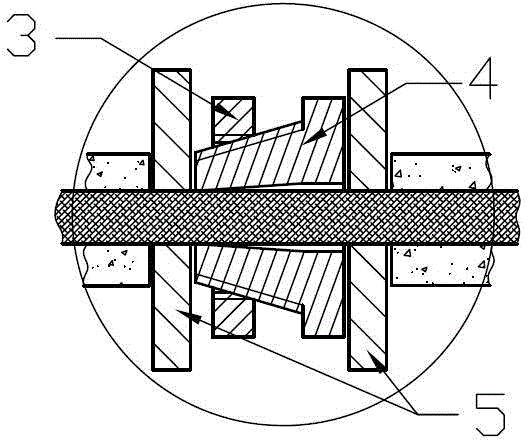

[0038] Such as figure 1 and figure 2 As shown, the thermocouple insulation positioner includes a positioning guide tube 1, a push nut 2, a positioning nut 3, a self-tightening positioning bolt 4, two insulating baffles 5, a pushing spring 6, and an insulating sleeve 7. The insulating sleeve The pipe 7 includes a first insulating sleeve 71 and a second insulating sleeve 72, wherein:

[0039] The center of the self-tightening positioning bolt 4 and the two insulating baffles 5 is provided with a through hole for the passage of the thermocouple 8, and the two insulating baffles 5 are respectively located at both ends of the self-tightening positioning bolt 4, and the thermocouple 8 passes through the insulation The baffle piece 5 and the self-tightening positioning bolt 4, the front end is penetrated in the first insulating sleeve 71 and the end extends out of the first insulating sleeve 71, and the rear end is penetrated in the second insulating sleeve 72, that is, the first i...

Embodiment 2

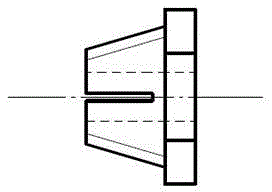

[0046] In this embodiment, on the basis of Embodiment 1, the self-tightening positioning bolt 4 is further improved, image 3 It is the front view of the self-tightening positioning bolt 4, the self-tightening positioning bolt 4 is a tapered bolt with a through hole, and its front end is a tapered thread segment. The above-mentioned groove is a strip groove, which is set on the tapered thread section at the front end of the tapered bolt. The length direction of the strip groove is parallel to the radial direction of the tapered bolt, and divides the end surface into two. The diameter of the through hole of the self-tightening positioning bolt 4 is slightly larger than the diameter of the thermocouple 8. When the positioning nut 3 is continuously screwed into the tapered thread section of the self-tightening positioning bolt 4, the diameter of the self-tightening positioning bolt 4 in the positioning nut 3 gradually increases. The increase makes the gap between the two sides of...

Embodiment 3

[0048] Such as Figure 4 As shown, on the basis of Embodiment 1 or Embodiment 2, in this embodiment, the rear end of the positioning guide tube 1 is also provided with a hexagonal head before pushing the nut 2, so as to facilitate the positioning between the front end of the guide tube 1 and the thermocouple channel 9. The threaded connection and disassembly between the space and the rear end and the push nut 2.

[0049] The outer tube wall at the front end of the positioning guide tube 1 is also provided with threads, so that the positioning guide tube 1 is screwed into the thermocouple channel 9, and the thermocouple can be disassembled and replaced after use.

[0050] The insulating sleeve 7 can be a ceramic tube, a quartz glass tube or a plastic tube, and the insulating baffle 5 can be a ceramic sheet, a quartz glass sheet or a plastic plate. In practical applications, the insulating sleeve 7 and the insulating baffle can also be made of Other insulating materials commonl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com