Microfluidic chip with rotary valve structure

A microfluidic chip, rotary valve technology, applied in fluid controllers, laboratory utensils, laboratory containers, etc., can solve the problem of low price and achieve the effect of avoiding instrument design, strong functionality and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A microfluidic chip with a rotary valve structure, including a valve core, a substrate and a bottom sheet, one surface of the substrate is bonded to the bottom sheet, and the other surface of the substrate is provided with a valve chamber and a flow channel, The valve chamber is provided with at least two valve chamber through holes, and each of the valve chamber through holes is respectively connected to the flow channel, and the substrate is also provided with an inlet and an outlet respectively connected to the flow channel; the valve The core includes a sealing layer and a supporting layer, the sealing layer is arranged in the valve chamber, the supporting layer is arranged on the sealing layer, and the sealing layer is provided with a conversion channel; when the supporting layer rotates, it drives the The sealing layer is rotated so that the conversion channel communicates with at least two through holes of the valve chamber.

[0046] The above-mentioned valve cha...

Embodiment 2

[0053] On the basis of embodiment 1, the sealing layer is an elastic polymer material; the total height of the supporting layer and the sealing layer is greater than the depth of the valve core accommodation cavity. With this technical solution, the sealing layer is in a compressed state, which ensures that the reagent will not volatilize or leak when flowing through the conversion channel of the sealing layer.

[0054] Further, the elastic polymer material is one of thermoplastic elastomer or rubber. The use of thermoplastic elastomer or rubber firstly utilizes its advantages of corrosion resistance, high and low temperature resistance, wear resistance and low price, and secondly utilizes its advantages of being elastic and not easily deformed after compression.

[0055] Further, the support layer is one of polycarbonate, cycloolefin copolymer, thermoplastic elastomer, copper or stainless steel. The supporting layer and sealing layer may be of the same or different materials...

Embodiment 3

[0073] On the basis of embodiment 2, this embodiment combines Figure 1-Figure 5 The present invention will be described.

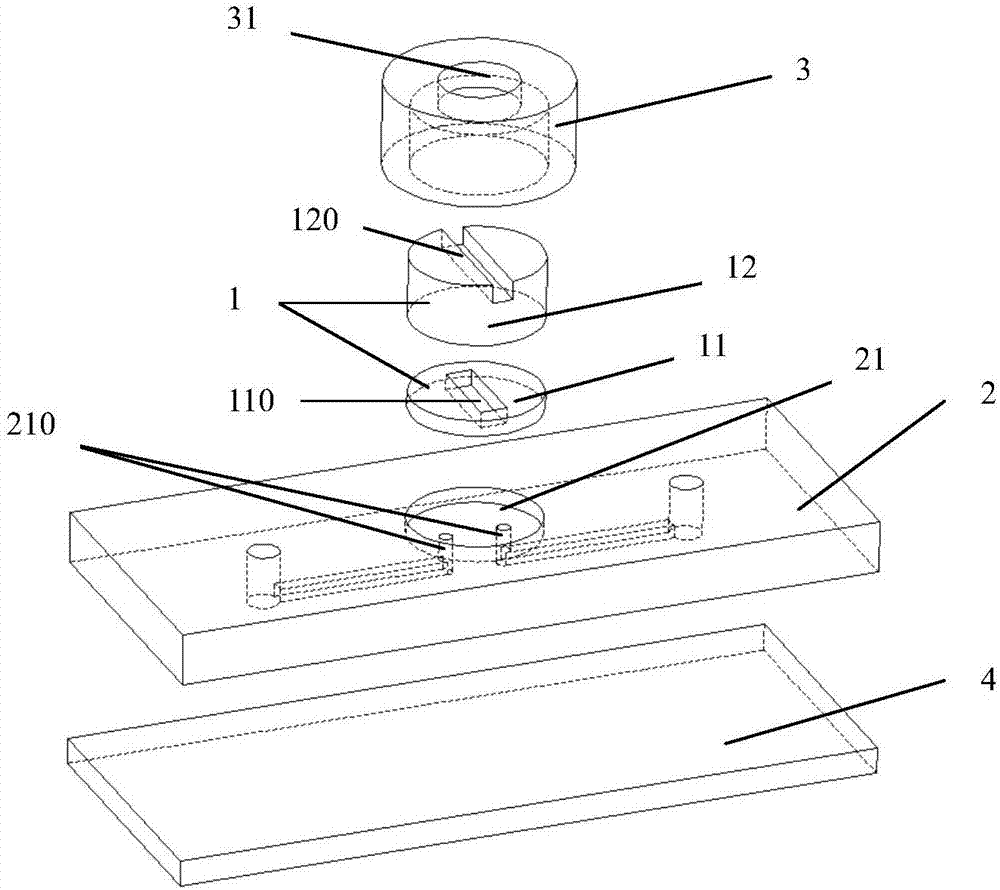

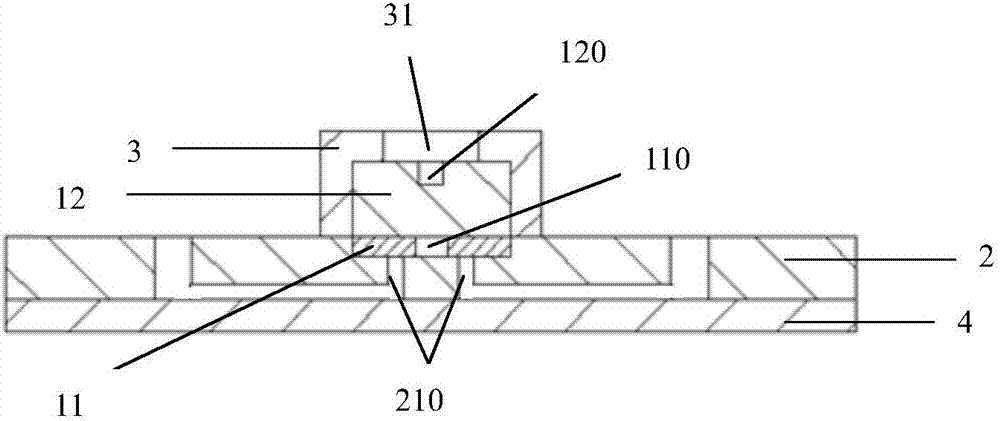

[0074] Such as Figure 1-Figure 3 A microfluidic chip with a rotary valve structure shown includes a valve core 1 , a substrate 2 , a gland 3 and a base 4 . The maximum thickness of the substrate 2 is 5mm, the thickness of the gland 3 is 2mm, and the thickness of the bottom sheet 4 is 1mm. The substrate 2, the gland 3 and the bottom sheet 4 are all made of polycarbonate material. The substrate 1 , the gland 3 and the bottom sheet 4 are formed by injection molding respectively.

[0075] The negative film and the base film are combined by chemical glue bonding. With this technical solution, the connection between the pressing cover and the substrate is firm.

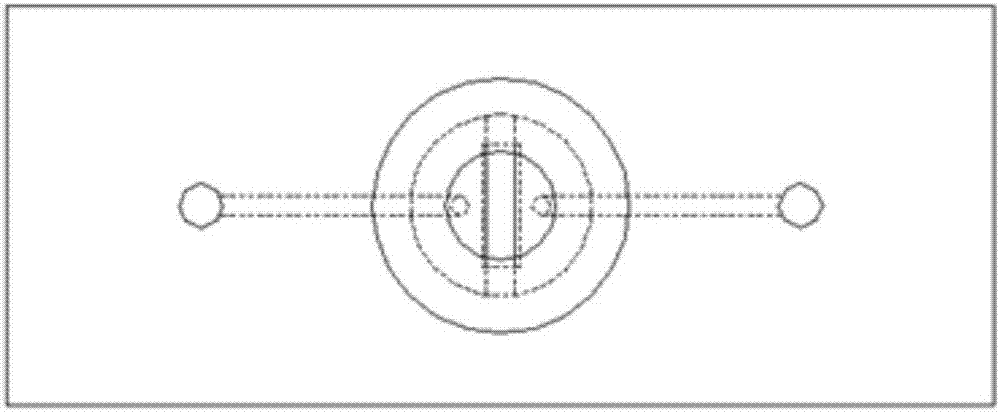

[0076] The substrate 2 is provided with a valve chamber 21 and a flow channel, the valve chamber 21 is on the top of the substrate 2, the flow channel is at the bottom of the substrate 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com