Multi-drill-bit electric drill for construction

A multi-bit, construction technology, applied in the direction of drilling/drilling equipment, portable drilling rigs, maintenance and safety accessories, etc., can solve the problems of increasing the power of the drill bit, failure of the motor speed to break through, scraping, etc., to improve efficiency, Good use value and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

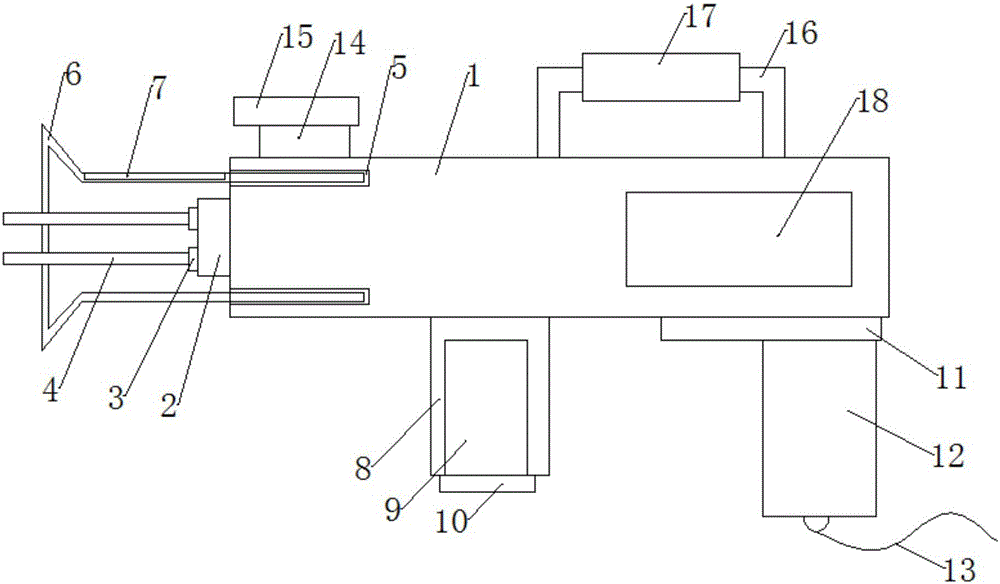

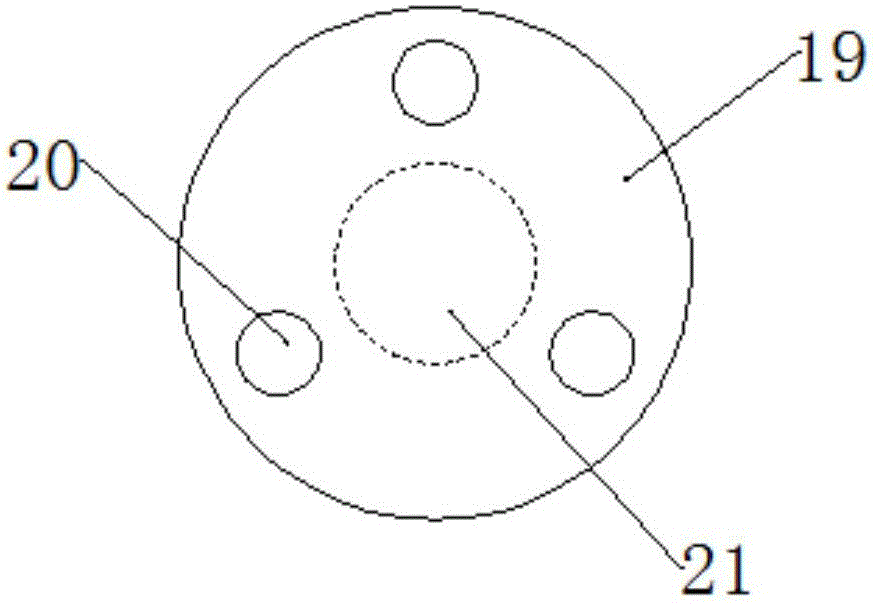

[0016] see figure 1 and figure 2 , the present invention provides a technical solution: a multi-bit electric drill for construction, including an electric drill body 1 and a drill seat 2, the drill seat 2 is arranged at the left end of the electric drill body 1, and a fixed ring 3 is arranged on the drill seat 2, and inside the fixed ring 3 A drill bit 4 is provided, a groove 5 is provided on the main body 1 of the electric drill, a protective cover 6 is provided in the groove 5, a scale 7 is provided on the protective cover 6, a front handle 8 is connected to the lower end of the electric drill main body 1, and a front handle 8 There is a drill bit box 9 inside, the lower end of the drill bit box 9 is provided with a sealing cover 10, the right end of the electric drill body 1 is provided with a sliding rail 11, the lower end of the sliding rail 11 is connected with a movable handle 12, and the lower end of the movable handle 12 is connected with a power connection 13. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com