Integrated pipe column for steam injection, leakage prevention, well backwashing and production of thermal production well

A technology for thermal recovery wells and backwashing wells, which is applied in the fields of producing fluids, flushing wellbore, wellbore/well components, etc., which can solve the problems of time-consuming and laborious oil layer temperature reduction, etc., and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The detailed description and technical content of the present invention are described below with the drawings, but the drawings are only for reference and description, and are not used to limit the present invention.

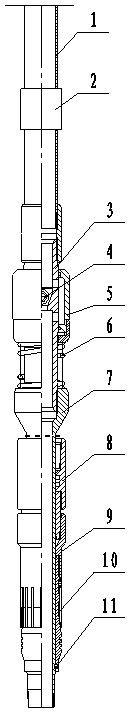

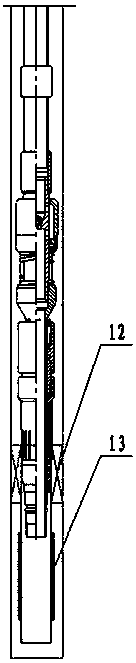

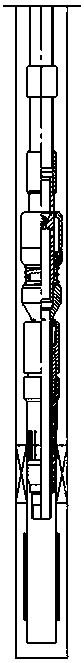

[0022] according to Figure 1 to Figure 4 , thermal recovery well steam injection, leakage prevention backwashing and production integrated pipe string, including oil pipe 1, lift pump 2, downhole multi-functional control valve 3, sealing plug 7 connected sequentially from top to bottom, the sealing plug The outer wall is covered with a sealing cylinder 8 and a downhole positioning tool 9, wherein the lower end of the sealing cylinder is connected to the upper end of the downhole positioning tool through a thread nipple, the outer wall of the downhole positioning tool 9 is provided with a positioning locking claw 10, and the lower end of the downhole positioning tool is fixed on the On the sealing plug, a horse-tooth buckle is provided on the outer wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com