Sulfur-doped carbon material or sulfur-nitrogen-doped carbon material and preparation method and application thereof

A technology of carbon materials and aza-carbon, which is applied in the field of sulfur-as-carbon materials or sulfur-aza-carbon materials and their preparation, can solve the problems of low-cost electrochemical performance, high oxygen reduction overpotential, etc., and achieve convenient batch preparation and overall Effect of cost reduction and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1. Preparation of S carbon

[0057] (1) Take a certain amount of S elemental substance and carbon black (Ketjen black EC600JD), and feed them according to the mass ratio S: carbon black = 15:85.

[0058] (2) Grind the S element and carbon black in a mortar for a little, so that the S element and carbon black are preliminarily mixed evenly.

[0059] (3) Pour the preliminarily homogeneous mixture in step (2) into secondary deionized water, and form a uniformly dispersed suspension (gel-like) by means of alternating stirring and ultrasonic waves.

[0060] (4) Dry the uniformly dispersed suspension in step (3) in an oven at 60° C., and then grind the dried mixture finely with a mortar.

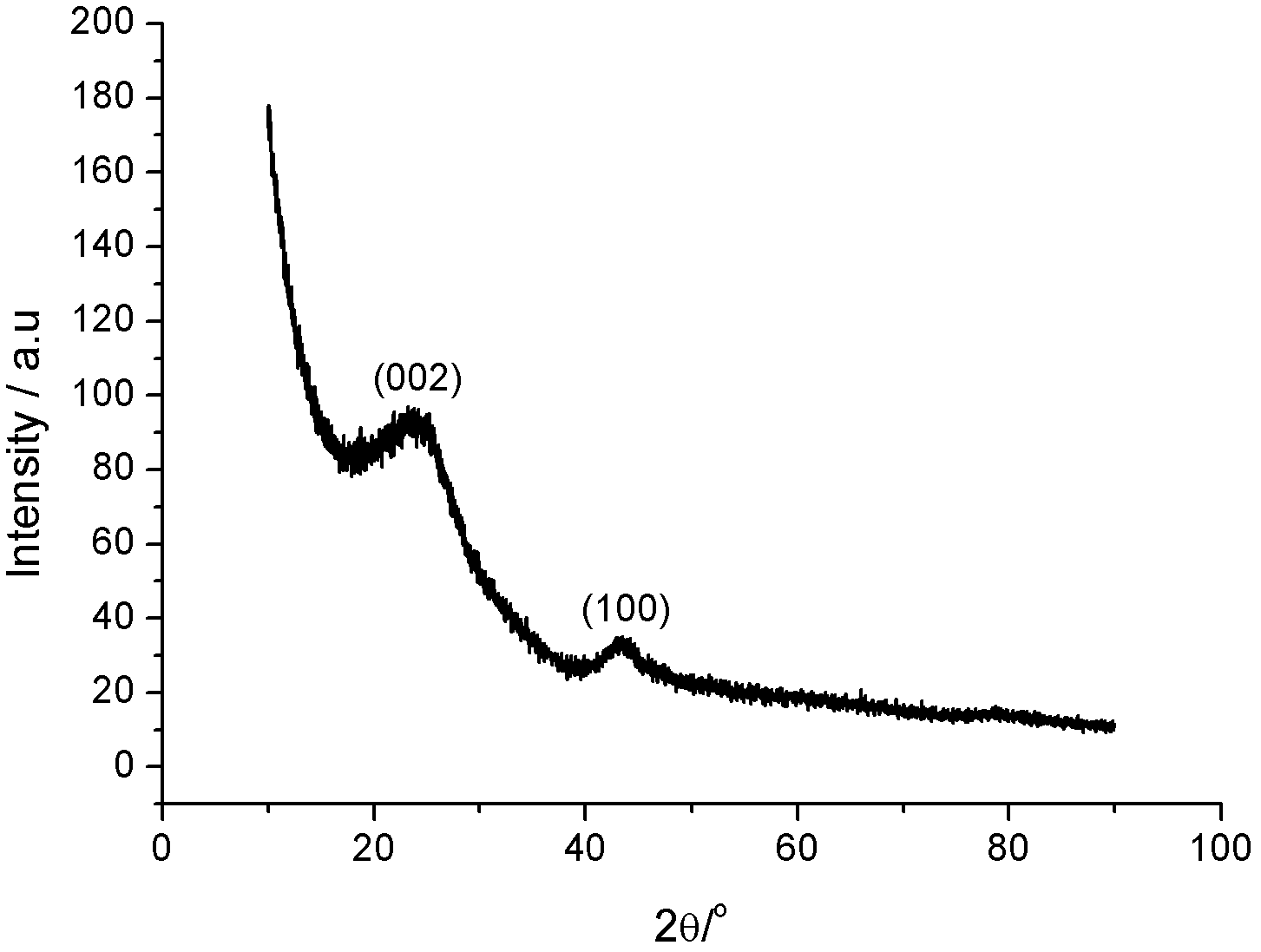

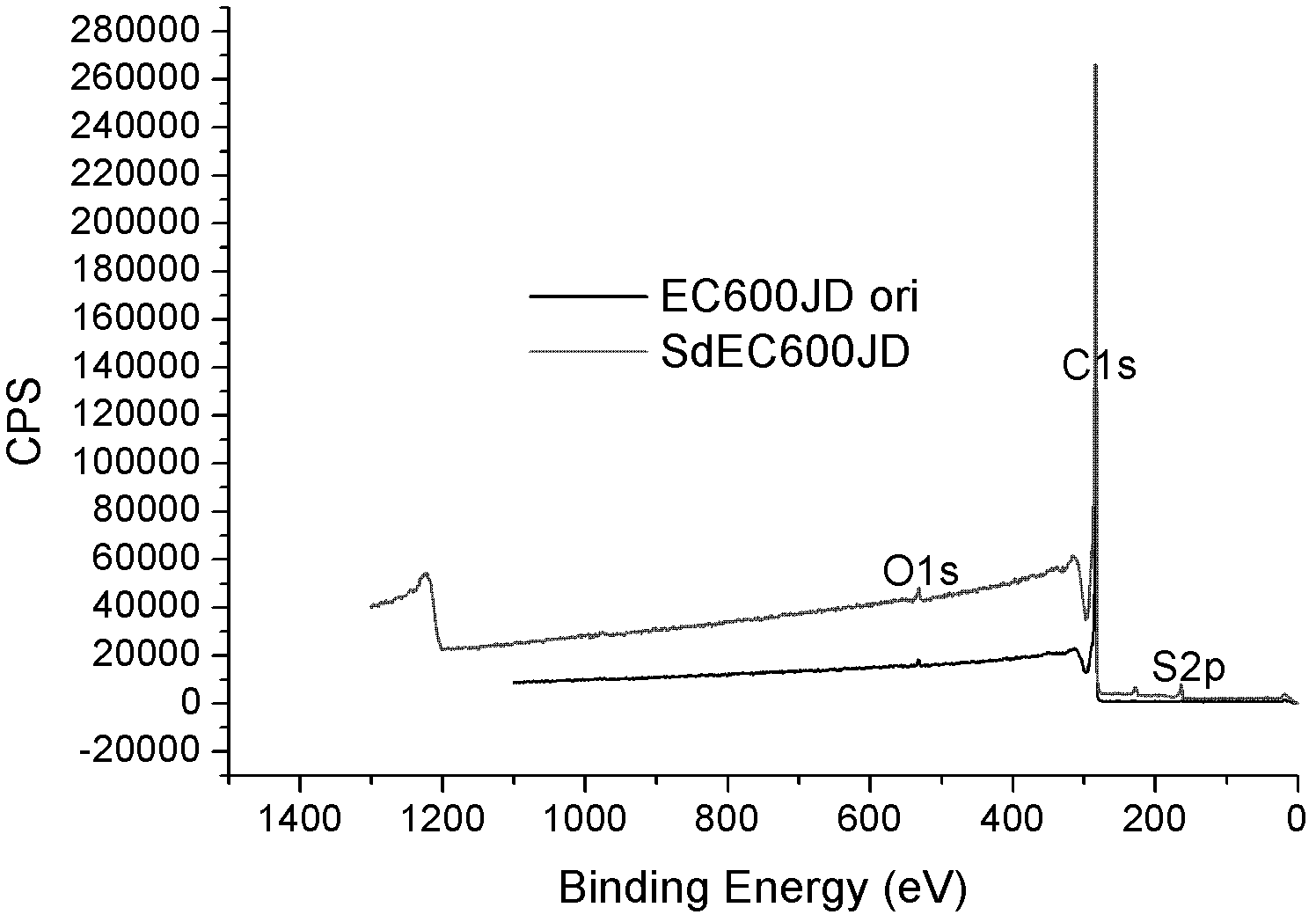

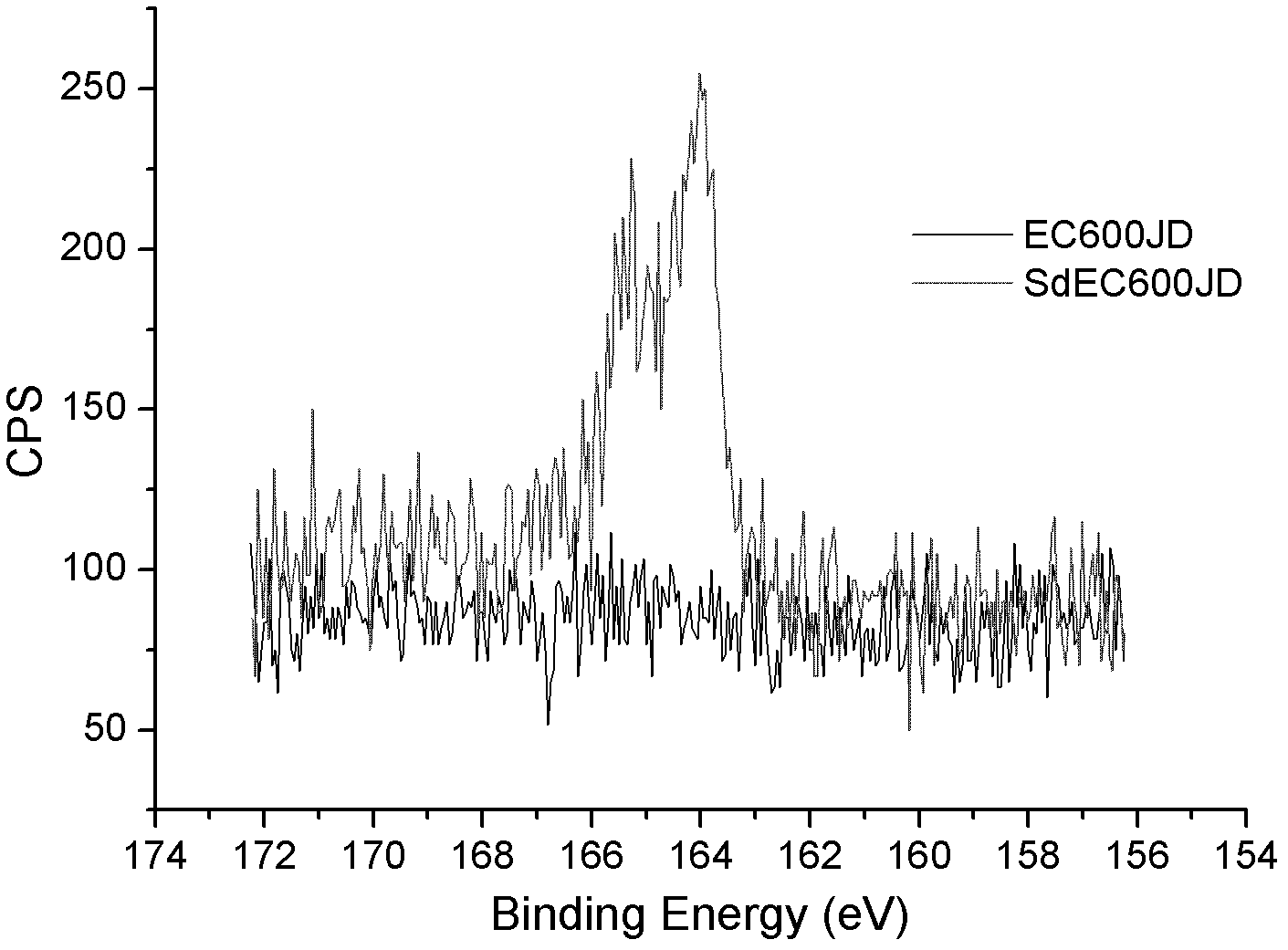

[0061] (5) Transfer the finely ground mixture in step (4) to enamel, put it into a tube furnace, and calcinate it at 900° C. for 5 hours under an Ar atmosphere to obtain a product, which is proved to be a carbonaceous carbon material by XRD analysis, XRD Spectrum such as figure 1 , figu...

Embodiment 2

[0077] 1. Preparation of S carbon

[0078] (1) Take a certain amount of S element and carbon black (Ketjen black EC600JD), and feed them according to the mass ratio S: carbon black = 25:75.

[0079] (2) Grind the S element and carbon black in a mortar for a little, so that the S element and carbon black are preliminarily mixed evenly.

[0080] (3) Pour the preliminarily homogeneous mixture in step (2) into secondary deionized water, and form a uniformly dispersed suspension (gel-like) by means of alternating stirring and ultrasonic waves.

[0081] (4) Dry the uniformly dispersed suspension in step (3) in an oven at 60° C., and then grind the dried mixture finely with a mortar.

[0082] (5) Transfer the finely ground mixture in step (4) to enamel, put it into a tube furnace, and calcinate it at 900° C. for 5 hours under an Ar atmosphere to obtain a product, which is proved to be a carbonaceous carbon material by XRD analysis, XRD Spectrum such as Figure 7 , Figure 7 Both ...

Embodiment 3

[0091] 1. Preparation of S carbon

[0092] (1) Take a certain amount of S elemental substance and carbon black (Ketjen black EC600JD), and feed them according to the mass ratio S: carbon black = 2:98.

[0093] (2) Grind the S element and carbon black in a mortar for a little, so that the S element and carbon black are preliminarily mixed evenly.

[0094] (3) Pour the preliminarily homogeneous mixture in step (2) into secondary deionized water, and form a uniformly dispersed suspension (gel-like) by means of alternating stirring and ultrasonic waves.

[0095] (4) Dry the uniformly dispersed suspension in step (3) in an oven at 60° C., and then grind the dried mixture finely with a mortar.

[0096] (5) Transfer the finely ground mixture in step (4) to enamel, put it into a tube furnace, and calcinate at 900° C. for 5 hours under an Ar atmosphere to obtain a product, which is proved to be a S carbonaceous material through XRD analysis, wherein The S impurity is 0.1wt.%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com