Preparation method of artificial rock core for simulating permafrost region hydrate stratum skeleton

A technology of stratum skeleton and artificial core, applied in the field of unconventional energy natural gas hydrate reservoir simulation experiments, can solve the problems of easy loosening, low core mechanical strength and low repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. After reading the present invention, those skilled in the art Modifications to various equivalent forms of the present invention fall within the scope defined by the appended claims of the present application.

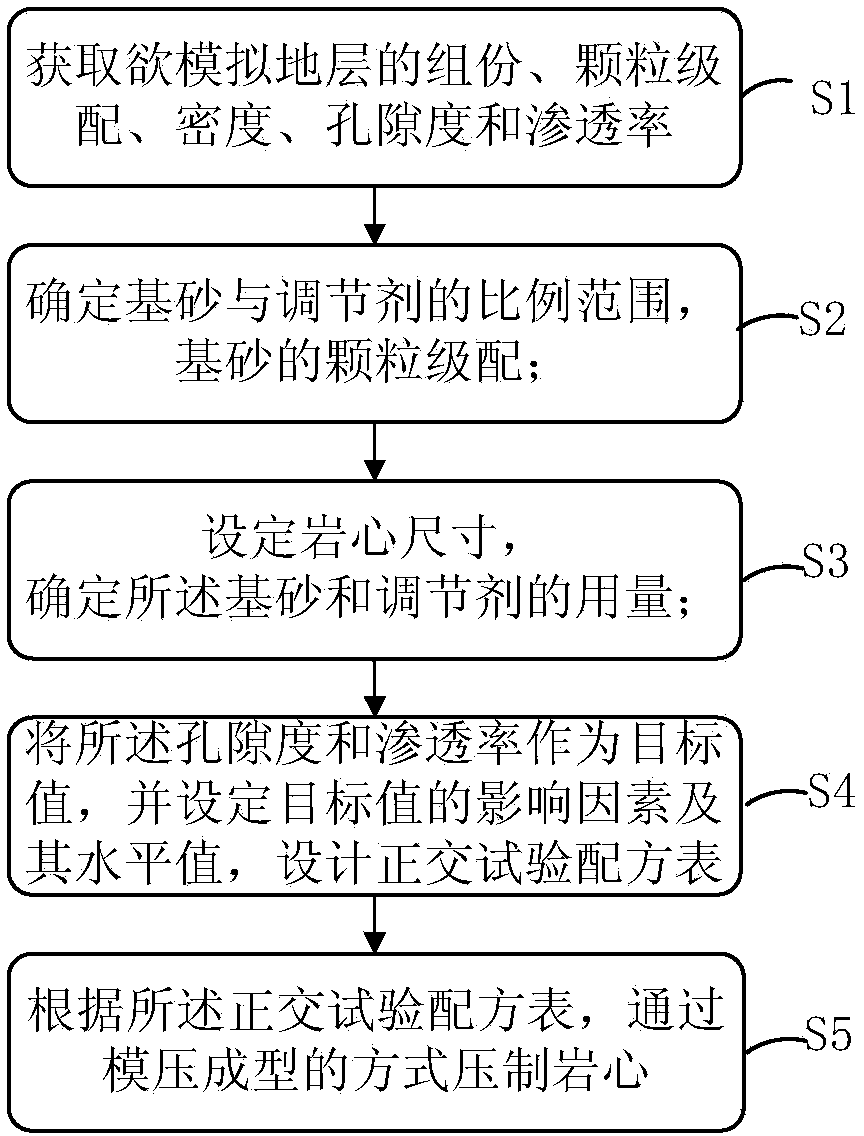

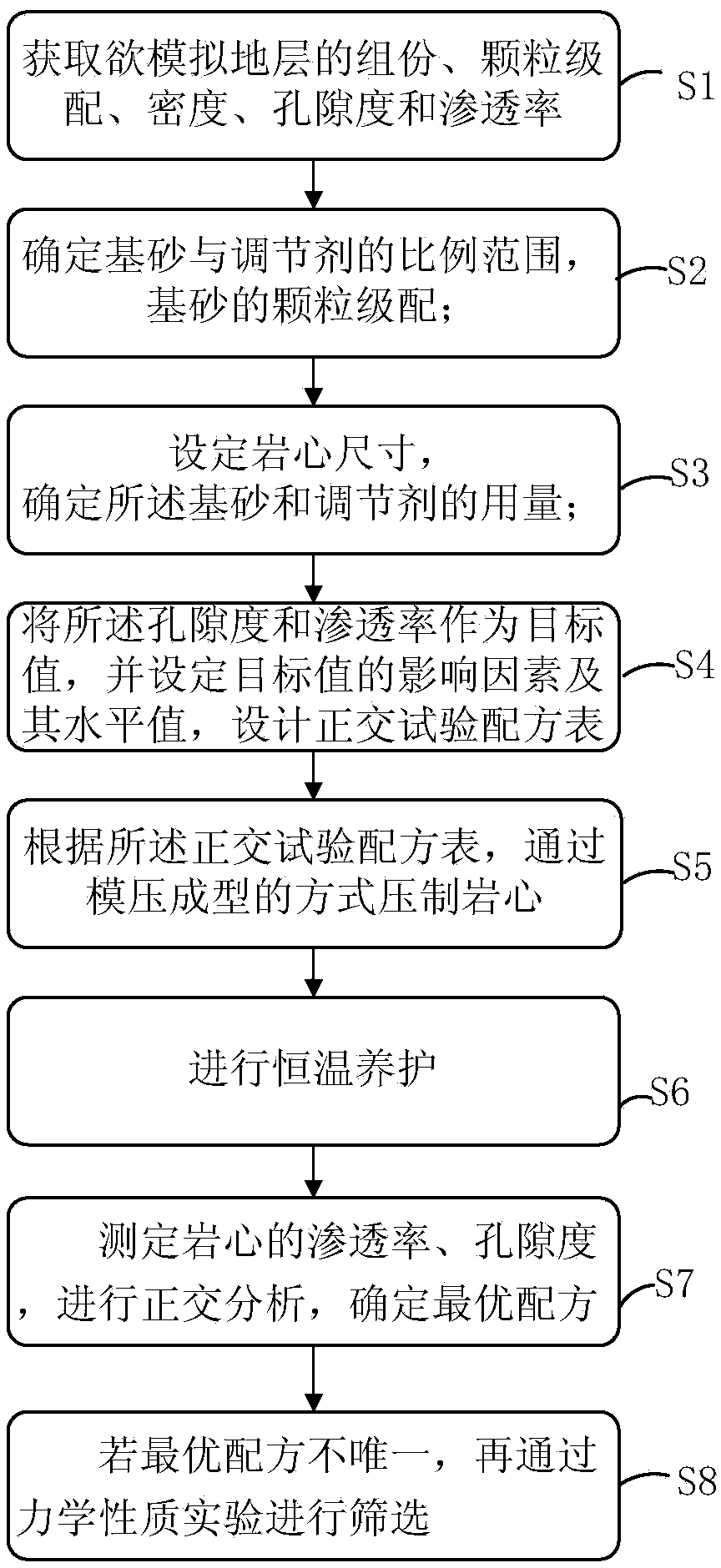

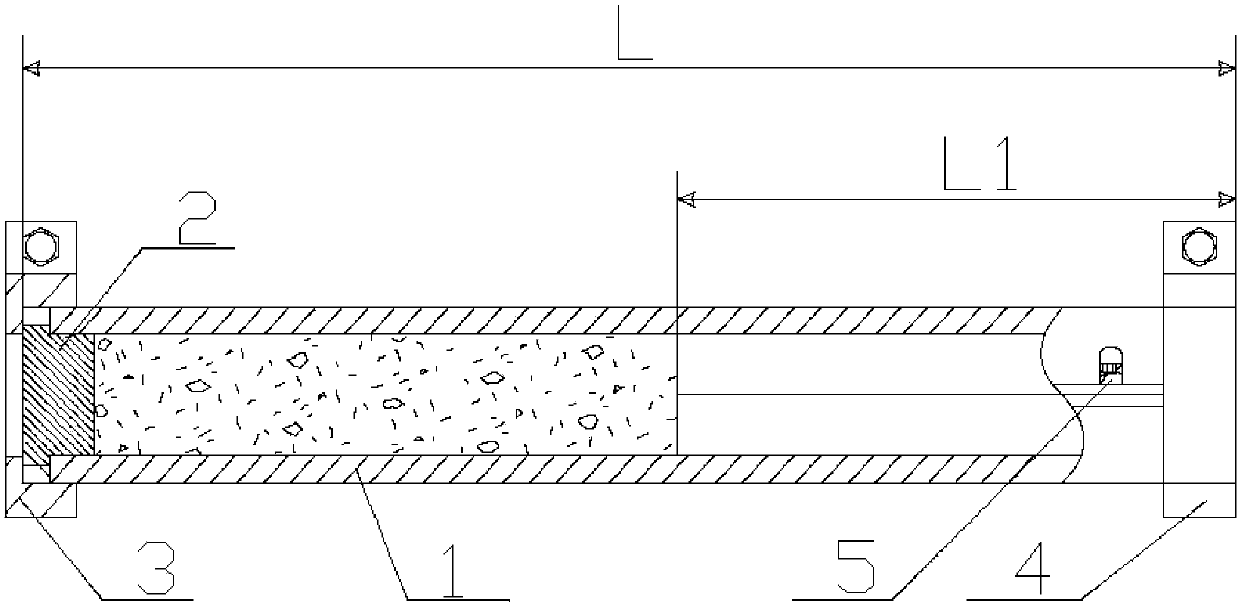

[0034] The invention provides a method for preparing artificial cores for simulating the framework of hydrate formations in permafrost regions, which solves the problem of the basic physical parameters of artificial cores used in existing hydrate simulation experiments, such as permeability, porosity and mechanical strength, and the original hydrate formations. Issues with large differences. see figure 1 , the step process flow of the artificial core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com