Railless sliding door

A sliding door and horizontal plane technology, applied in the field of trackless sliding doors, can solve the problems of high freight, poor overall self-adjustment ability of guiding, and unstable operation of trackless sliding doors, etc., and achieve the effect of ensuring smooth operation and increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention will be further described below in conjunction with the embodiment shown in the accompanying drawings:

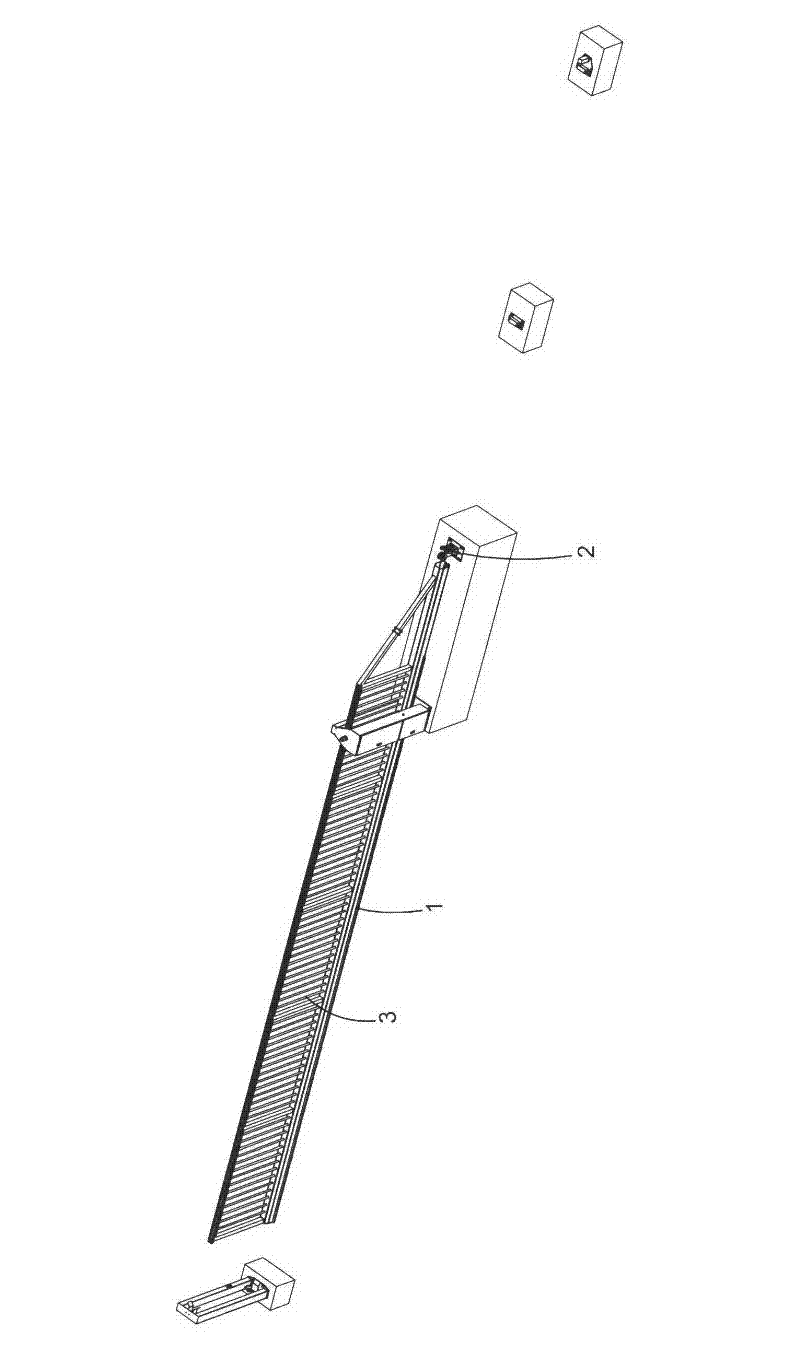

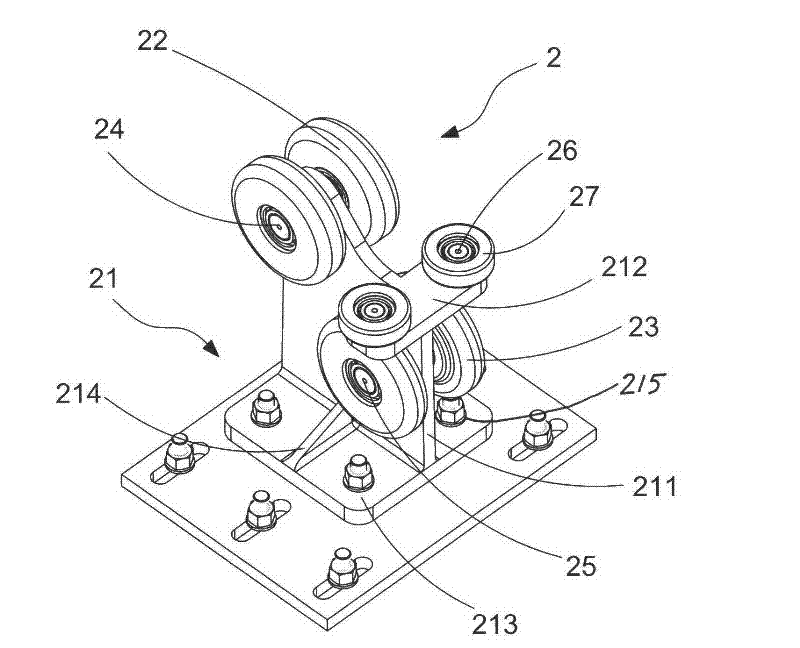

[0018] Such as figure 1 As shown, the entire translation door is mainly composed of a bottom beam 1, a support roller assembly 2, a door body 3 and power device components.

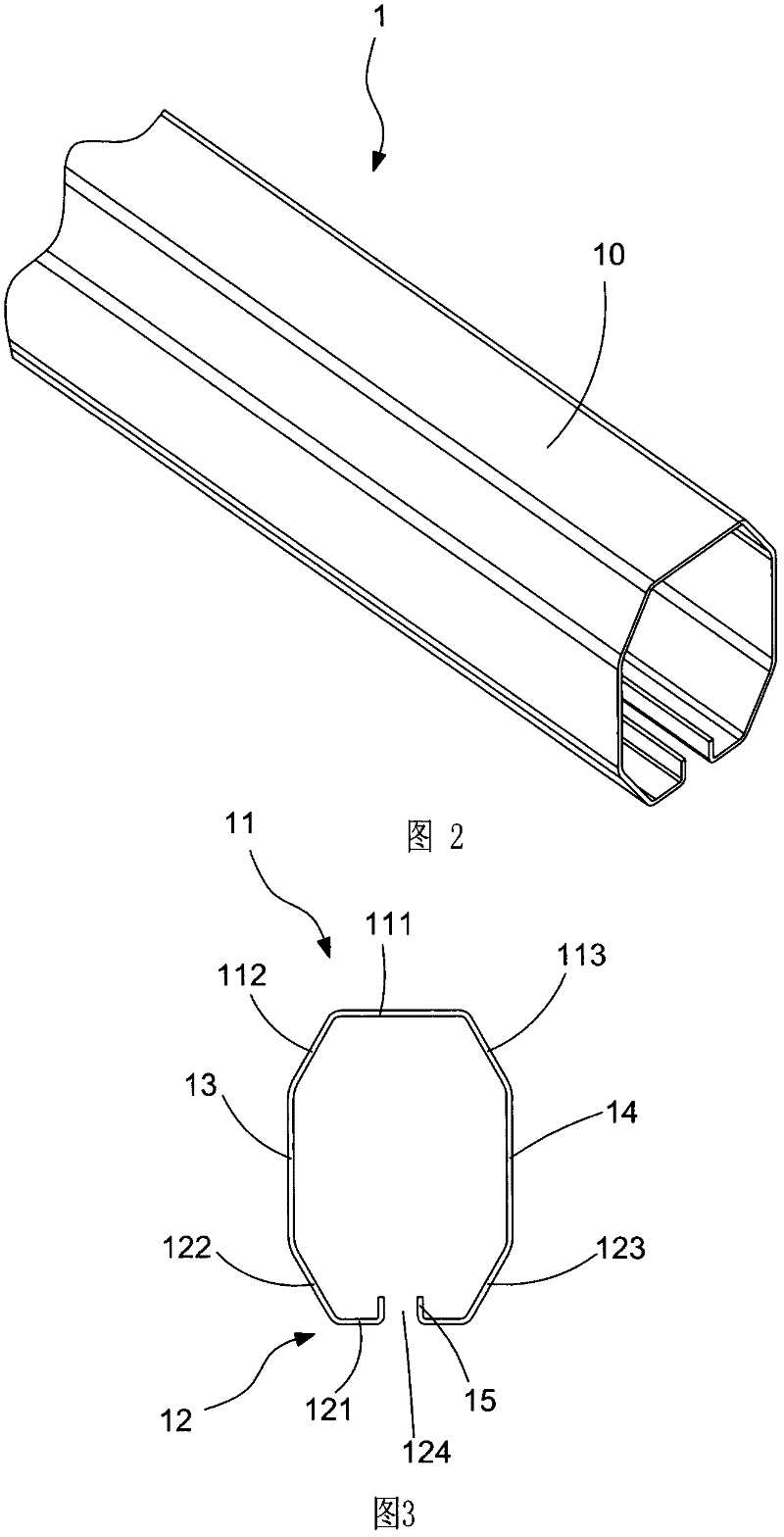

[0019] Such as figure 2 As shown, the bottom beam 1 is a hollow body, including a hollow body 10, and the two ends of the hollow body 10 have end caps (not shown in the figure).

[0020] Such as image 3 As shown, the hollow body 11 is substantially in the shape of a square with four side walls, and the inner wall is composed of an upper working surface 11 , a lower working surface 12 , a left side 13 and a right side 14 . The upper working surface 11 includes an upper horizontal plane 111 at the middle, an upper left slope 112 at the left end, and an upper right slope 113 at the right end, and the lower working surface 12 includes a lower horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com