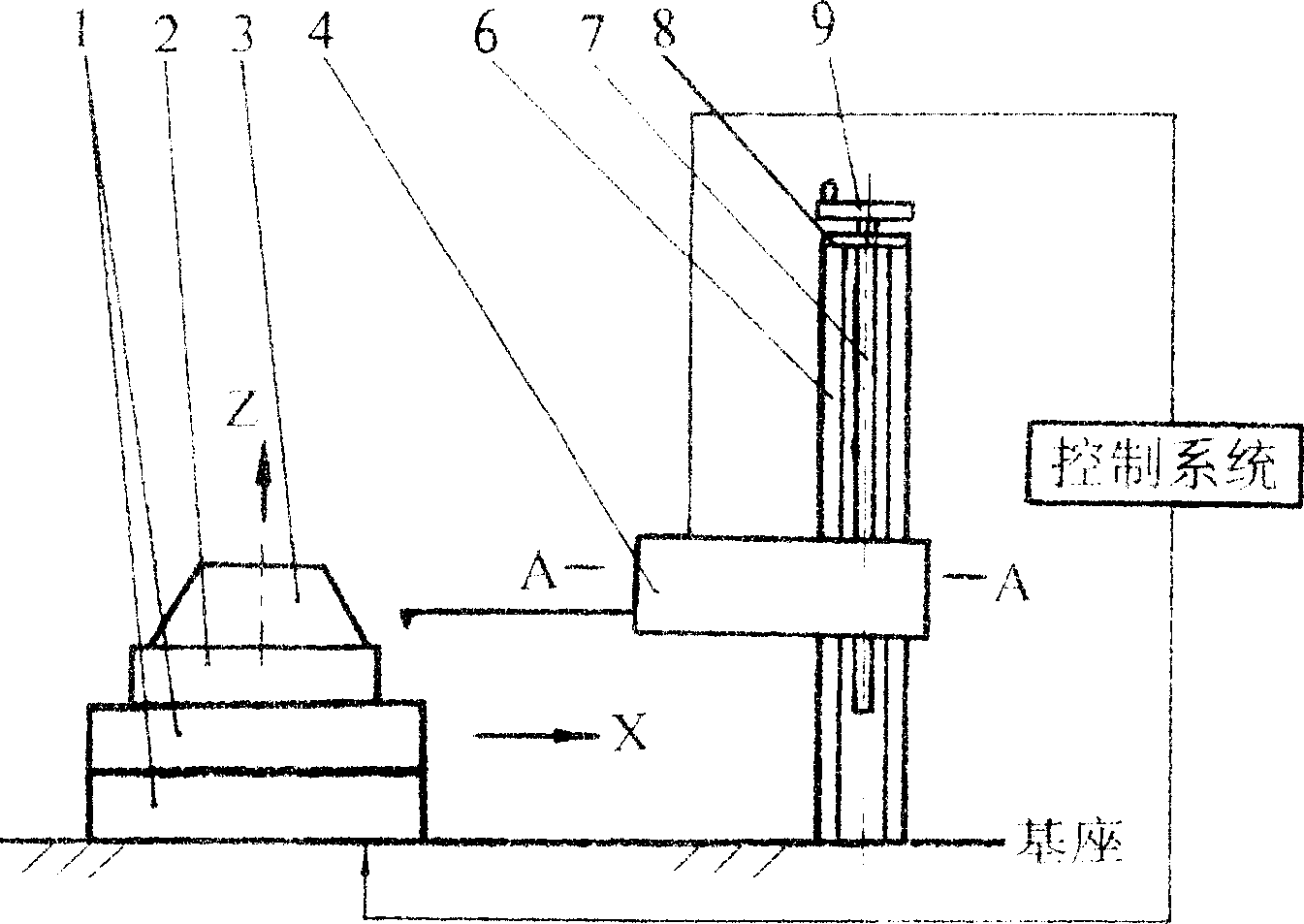

Measuring device for inner-rim large-flange spherical radius of taper roll bearing and measuring method

A tapered roller bearing, spherical radius technology, applied in the field of measurement, to achieve the effect of ensuring measurement accuracy, dimensional accuracy, and parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

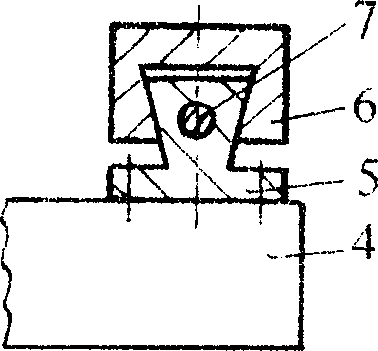

Method used

Image

Examples

Embodiment

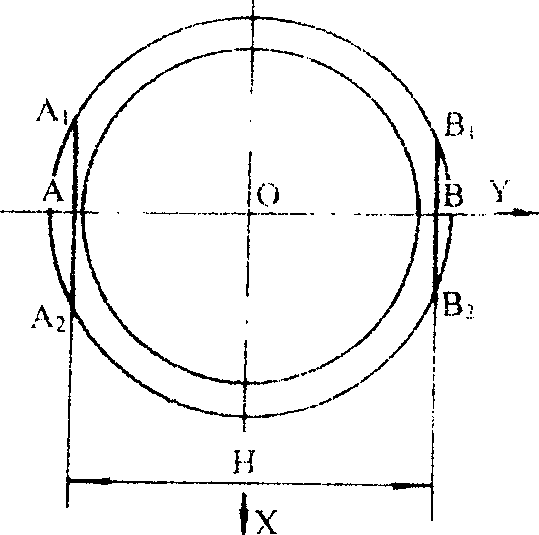

[0042] Taking the tapered roller bearing inner ring 7909 / 02 produced by a bearing factory as an example, it is known from the design drawings that the design value of the spherical radius R of the large rib is 225.941 +1 mm, after preliminary inspection with the standard roller coloring method, the result is that the spherical radius of the large rib basically meets the design requirements. Now use this device to measure, the value of H is 69.5mm, after checking A 1 AAA 2 and B 1 BB 2 After measuring the contours of the contours respectively, the arc radii of the fitted sections are r 1 =292.948mm, r 2 =293.101mm, the spherical radius of the large rib is finally obtained as R=295.078mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com