Bending die for cooling pipe in poloidal field coil support and method of bending die

A technology of coil support and cooling pipe, applied in the field of pipe bending and forming, can solve the problems of unsuitable production of small-scale pipe fittings, difficult to control the overall size and shape, and high price of CNC pipe bending machines, so as to compensate for the inconsistency of product size. Qualified, convenient for one-time molding, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

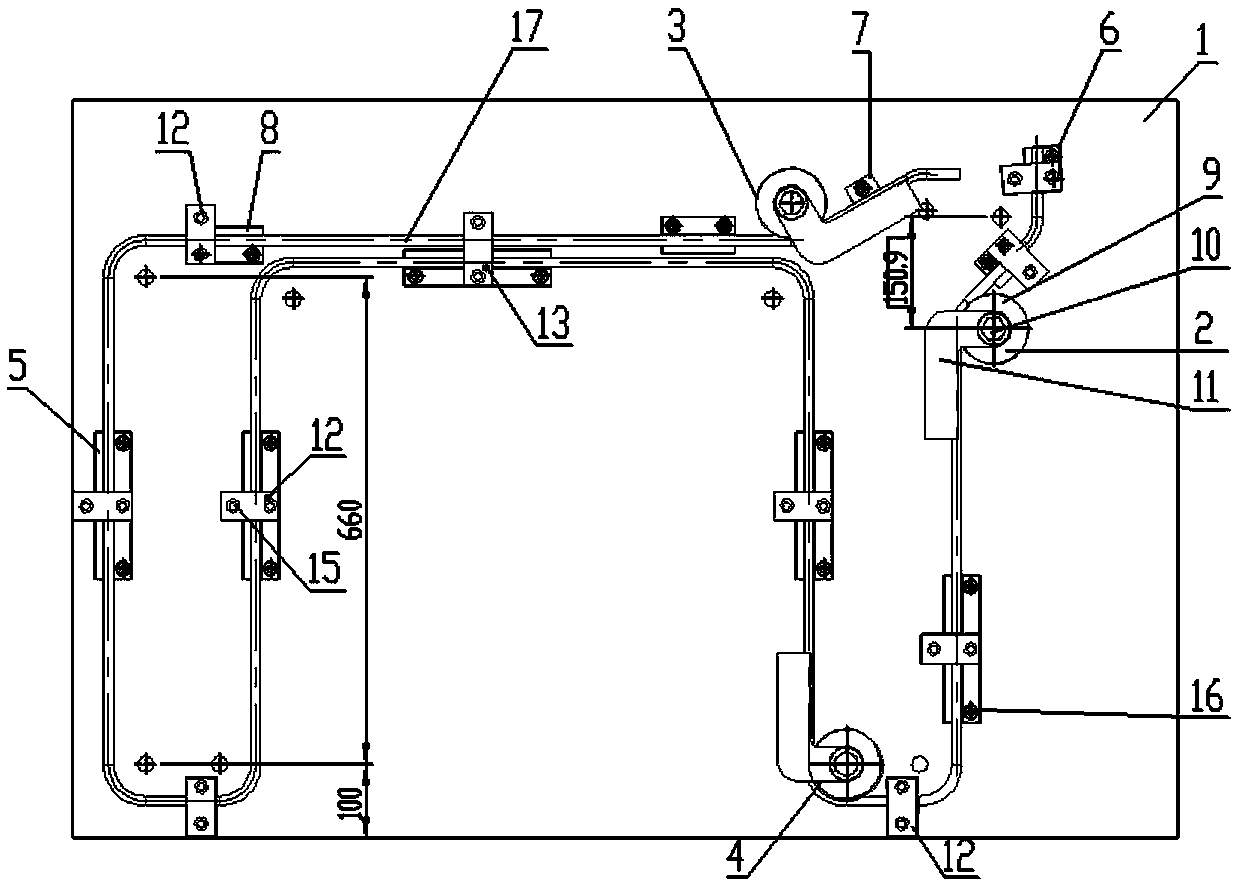

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings, but not as a basis for limiting the present invention. The following dimensions are all in millimeters.

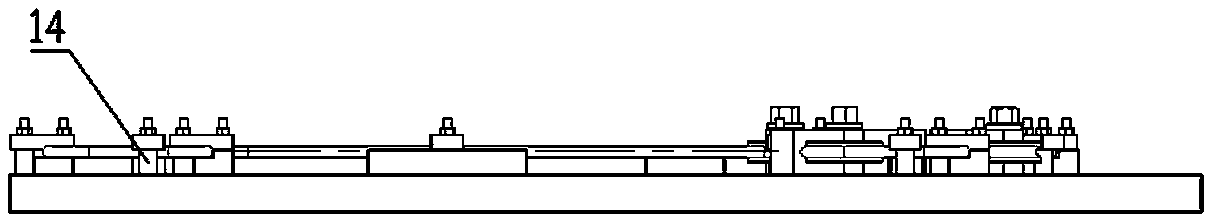

[0052] Such as figure 2 , 3 As shown, a bending die for cooling pipes supported by poloidal field coils mainly includes a curved bottom plate 1, a first bending die 2, a second bending die 3, a third bending die 4, a first baffle plate 5, a second bending die The second type of baffle 6, the third type of baffle 7, the fourth type of baffle 8, the roller 9, the positioning shaft 10, the bent handle 11, the first type of pressure plate 12, the second type of pressure plate 13, the washer 14, the screw and the nut 15 and hexagon socket head cap screws 16;

[0053] A hole for positioning the shaft 10 is placed at the position where the bending radius round point of the cooling pipe 17 is located on the curved bottom plate 1;

[0054] The first bending die 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com