Production process of two-time formed high-accuracy ceramic ferrule

A technology of ceramic ferrule and secondary molding, applied in coating and other directions, can solve the problems of metal core rod deflection, low qualification rate and high injection pressure, and achieve the effect of avoiding bending, improving molding accuracy and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

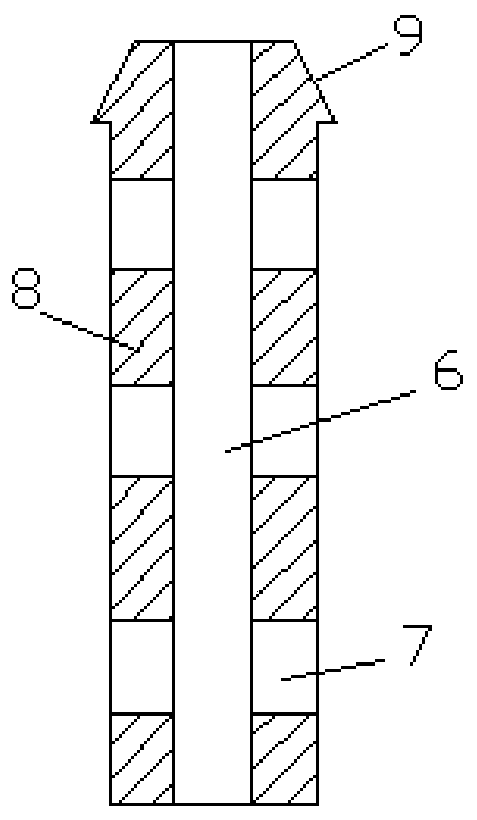

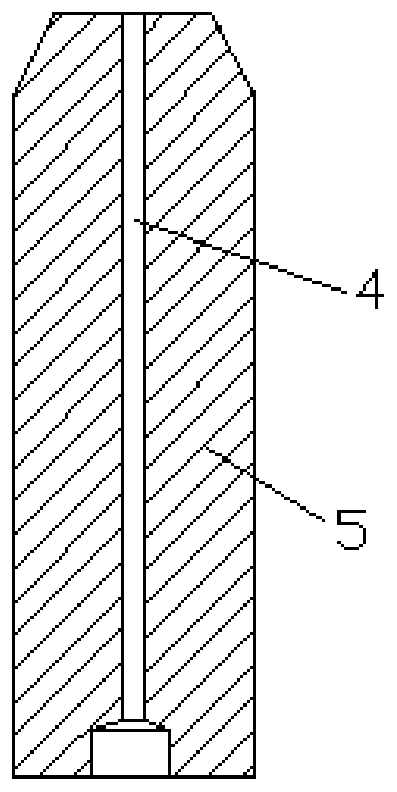

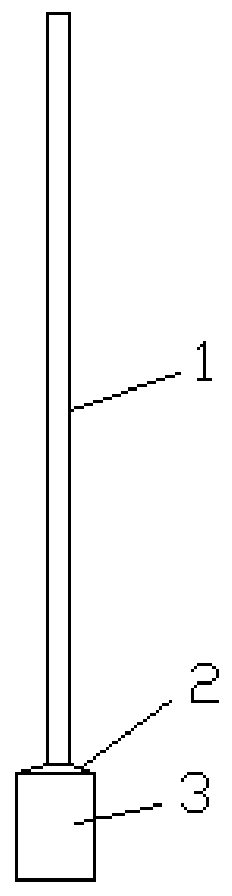

[0022] Combine below Figure 1 to Figure 3 And further illustrate the technical solution of the present invention through specific examples.

[0023] A production process for overmolding a high-precision ceramic ferrule, comprising the following steps:

[0024] Internal mixing, mix the raw materials of the ceramic ferrule, mix them evenly, and then introduce them into the internal mixer. The temperature of the internal mixer is set at 162-165°C, and the internal mixing time is 30-35 minutes. Refining temperature, so that the raw materials are fully fused;

[0025] Crushing, the rubber blocks are first pressed into tablets, and then imported into a pulverizer for pulverization to obtain granules, which is conducive to subsequent hot melting;

[0026] One-time injection molding, the particles are introduced into the first injection machine, hot-melted, and injected once through the first mold on the first injection machine, the injection pressure is 120MPa, and the tubular int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com