A liquid crystal module

A liquid crystal module and rib positioning technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of high production cost and low production efficiency, and achieve the effect of efficient and simple positioning protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

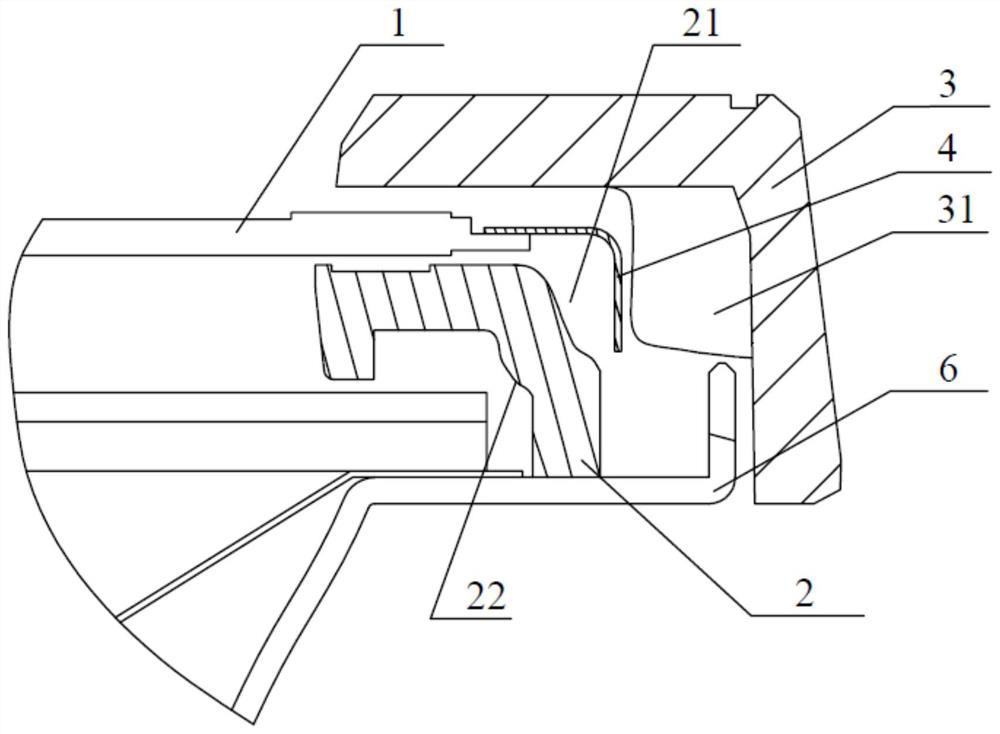

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

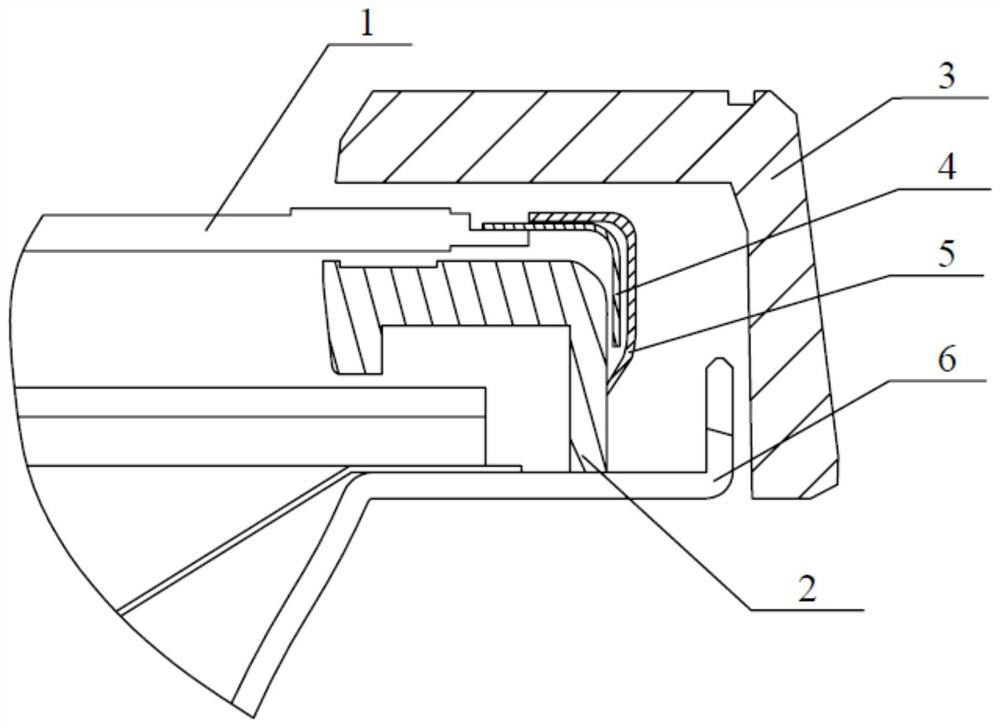

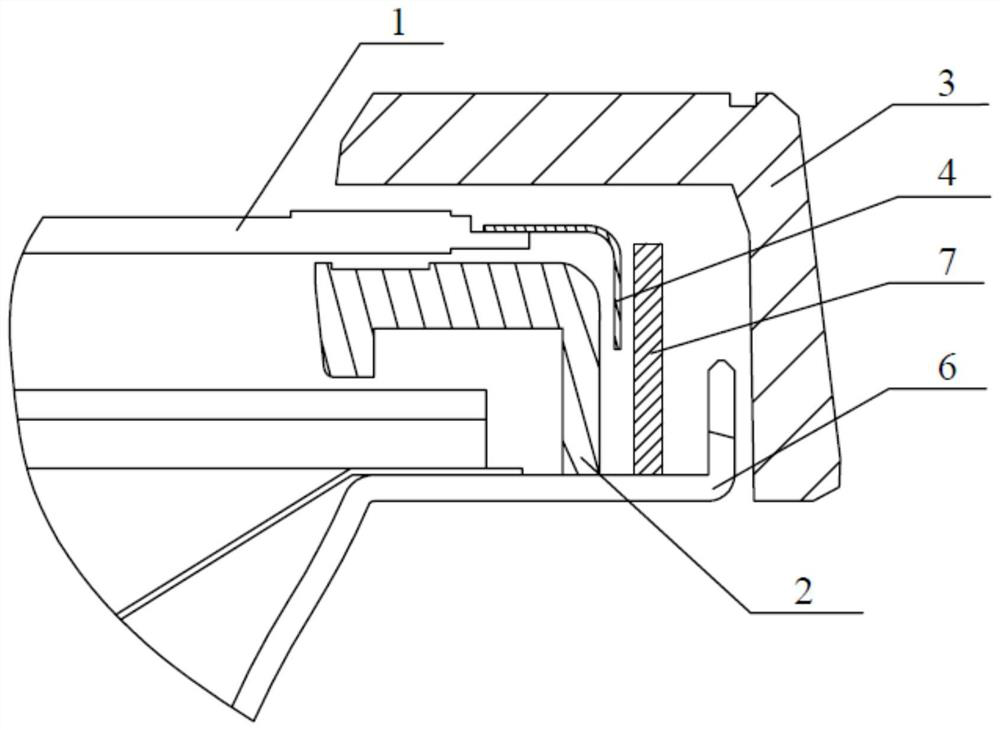

[0034] Such as image 3 As shown, a liquid crystal module provided by the present invention includes a glass panel 1, a middle frame 2, a front frame 3 and a back plate 6, wherein:

[0035] The middle frame 2 is located under the glass panel 1, the middle frame 2 is installed on the back plate 6, the front frame 3 covers the sides of the glass panel 1, the middle frame 2 and the back plate 6, and forms a cavity that can accommodate COF4 with the three . The outer wall of the middle frame 2 is provided with a groove 21 , the inner wall of the surface frame 3 is provided with a rib 31 , one end of the COF 4 is set on the glass panel 1 , and the other end is pressed against the rib 31 and bent toward the direction of the groove 21 . In the present invention, ribs 31 are provided at the position corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com