A wrapping paper pad for internally drawn copper coils

A copper coil tube and paper pad technology, applied in the field of packaging paper pads, can solve the problems of easy bending or breaking, and achieve the effects of not being easy to bend or break, reducing production costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

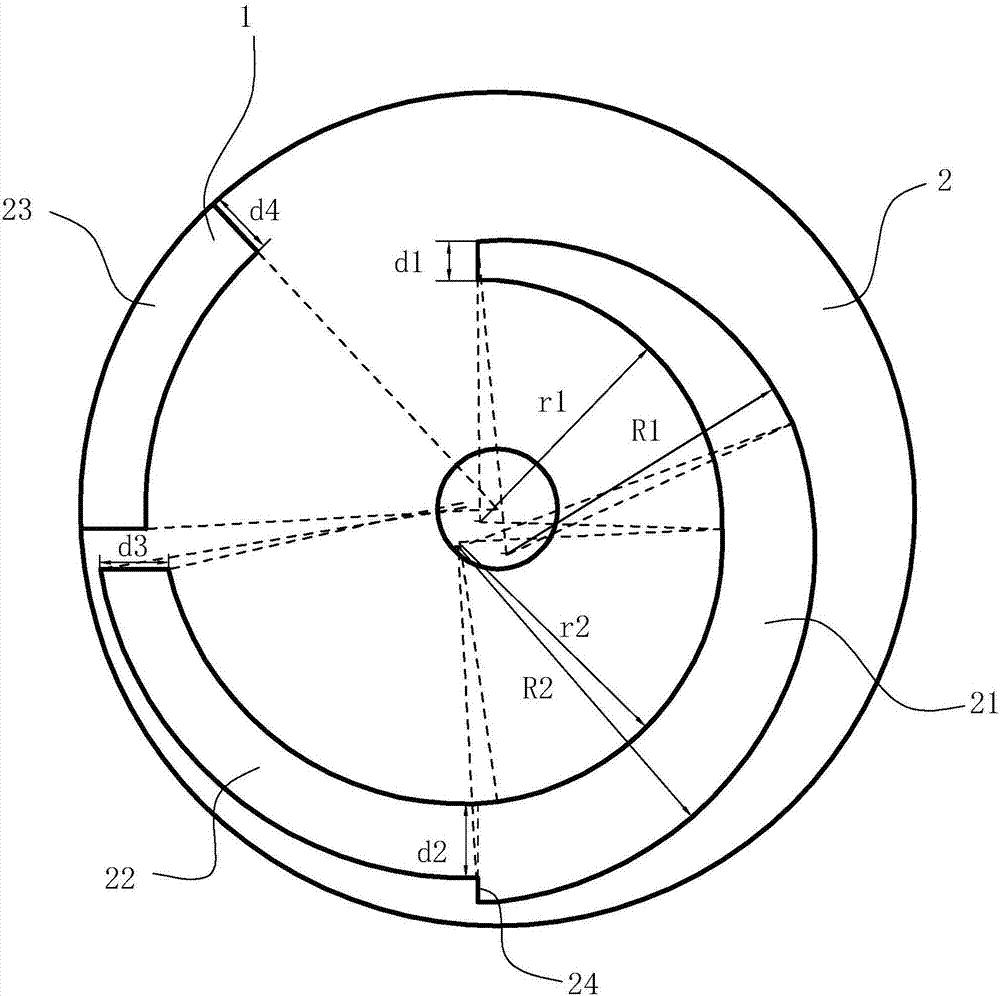

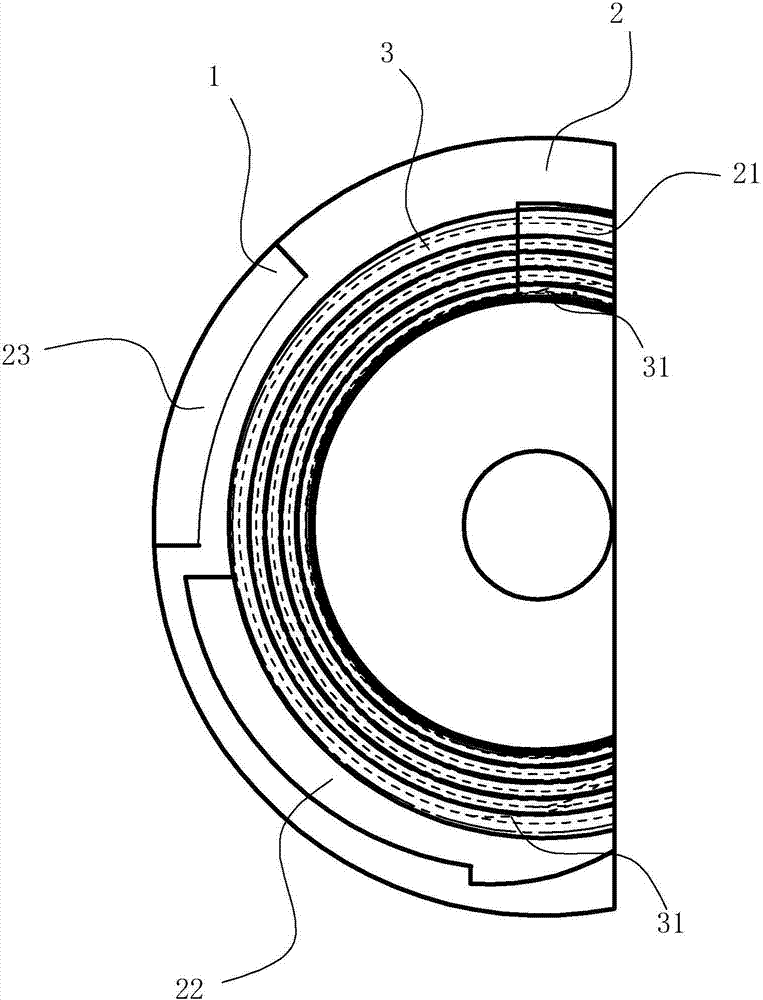

[0017] Such as figure 1 , 2 As shown, the wrapping paper pad used for the inner-drawing copper coil in this embodiment is formed by superimposing the first paper pad 1 and the second paper pad 2 of the circular ring, the first paper pad 1 The first paper pad 1 is a spacer and the second paper pad 2 is a functional part. The first paper pad 1 and the second paper pad 2 have an outer diameter of 1040mm, an inner diameter of 150mm, and a thickness of 5 ~6mm, the second paper pad 2 is superimposed on the top of the first paper pad 1 and is in contact with the copper coil, and an arc-shaped hollow is cut and formed on the second paper pad 2 for the interlaced layer 31 of the copper coil 3 to be inserted The rotation direction of the hollow part is opposite to the extraction direction of the copper coil 3, and the area of the hollow part is 6600...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com