Electromagnetic scale-inhibiting and descaling device and evaporating system

An electromagnetic and scale-inhibiting technology, applied in evaporator accessories, descaling and water softening, water/sludge/sewage treatment, etc. To achieve the effect of high descaling and anti-scaling efficiency, improving heat exchange efficiency and improving heat exchange performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

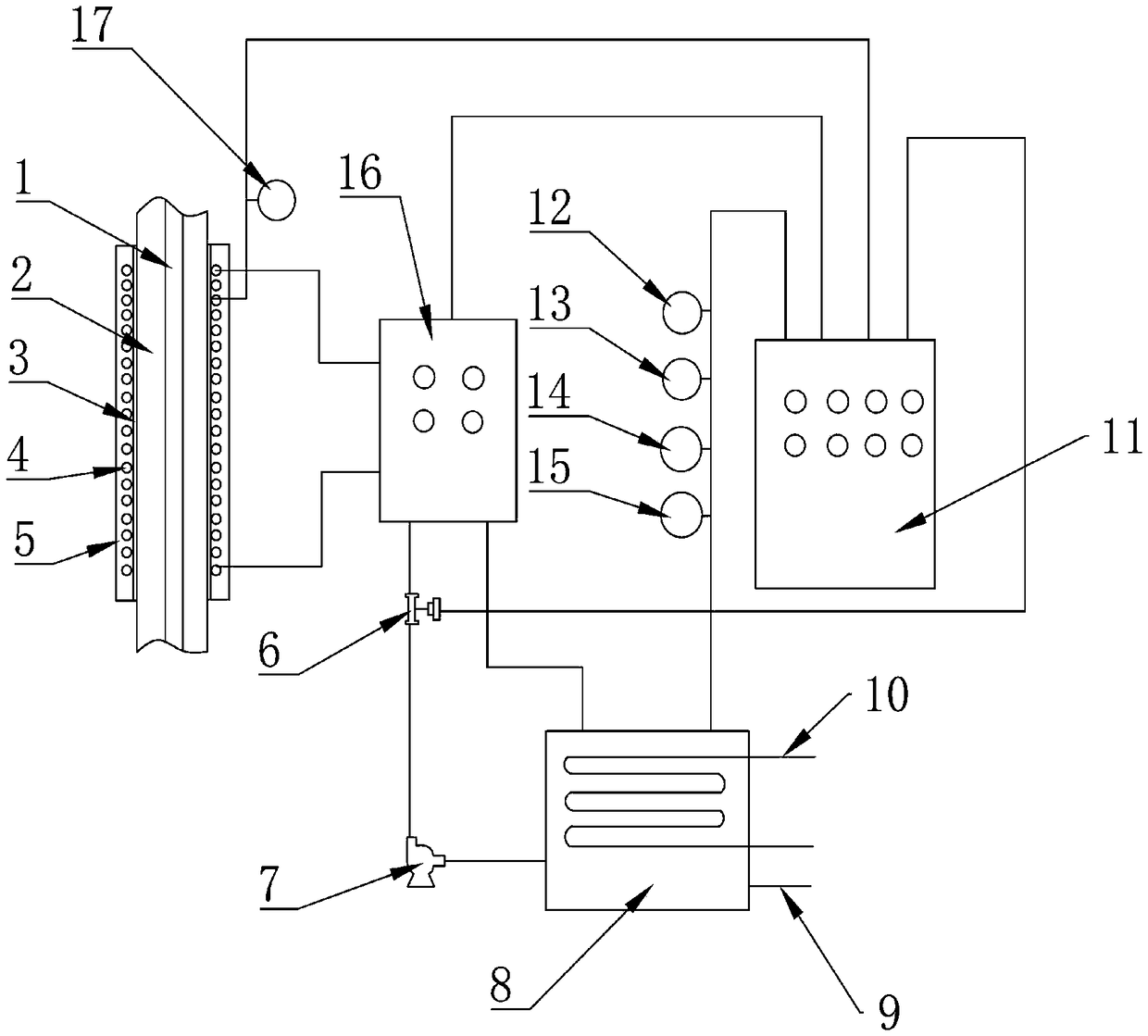

[0091] The evaporation system of this embodiment includes an evaporator 22, and the electromagnetic anti-scaling and descaling device 29 is connected to the evaporation circulation pipeline, inlet pipeline or outlet pipeline of the evaporator 22, and is connected to the inlet pipeline or outlet pipeline of the evaporator 22. Evaporating the circulating fluid for magnetization can achieve the effect of magnetization anti-scaling and descaling.

[0092] The fluid in the heat exchange coil 10 in the cooling circulating water tank 8 of the cooling cycle system is preferably the material supplied to the evaporator 22 to realize the effect of cooling the cooling water, and at the same time realize the preheating of the material and recover the waste heat of the cooling water , improve thermal efficiency.

[0093] The fluid flow rate of the evaporation circulation pipeline of the evaporator 22 is large. Connecting the electromagnetic anti-scaling and descaling device 29 to the evapor...

Embodiment 2

[0095] The difference from Embodiment 1 is that it also includes a separator 23, a circulation pipeline is provided between the evaporator 22 and the separator 23, and an electromagnetic anti-scaling and descaling device 29 is connected to the circulation pipeline. The gas-liquid mixture in the evaporator 22 flows into the separator 23, the gas separated in the separator 23 is utilized, and the liquid separated by the separator 23 flows back into the evaporator 22 along the circulation pipeline, and the electromagnetic anti-scaling and descaling device 29 Installed on the circulation pipeline between the evaporator 22 and the separator 23, the fluid flow in the circulation pipeline is large, which can fully magnetize the fluid in the evaporation system.

Embodiment 3

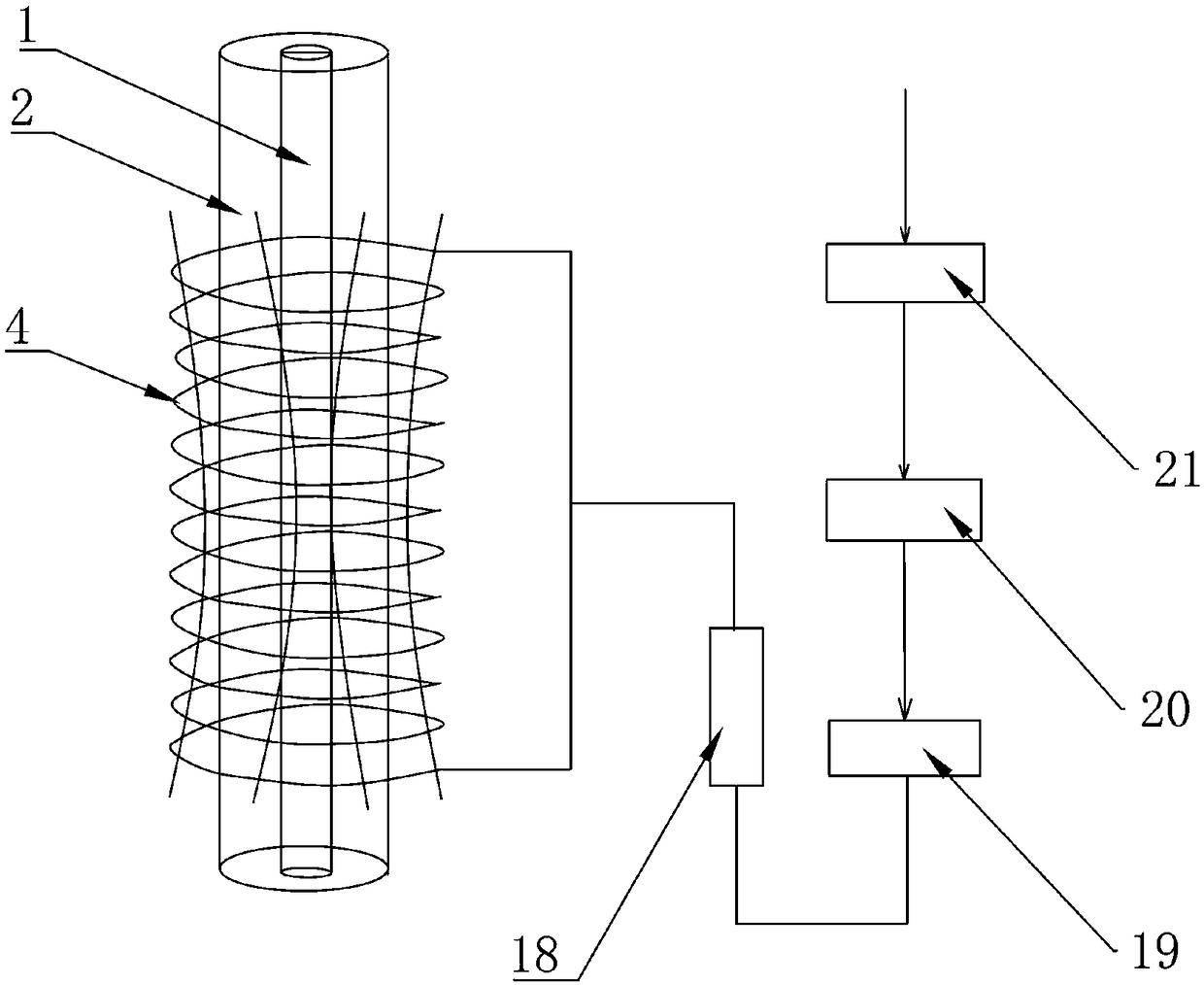

[0097] The difference from Example 1 is that the combination Figure 5 As shown, it also includes a separator 23 , a steam scrubber 24 , a steam compressor 25 , a high-temperature condensed water tank 26 , a condensed water preheater 27 , a low-temperature condensed water collecting tank 28 , and an electromagnetic anti-scaling and descaling device 29 .

[0098] Specifically, the raw material first enters the condensed water preheater 27, absorbs the waste heat of high-temperature condensed water, and then enters the evaporator 22. After heating, it becomes a vapor-liquid two-phase flow and enters the separator 23. The separated secondary steam passes through the steam scrubber 24 Purified after treatment, the purified steam enters the steam compressor 25 for compression, temperature increase and pressurization, and then enters the shell side of the evaporator 22. After heat exchange, the condensed water is discharged from the bottom of the shell side of the evaporator 22 to hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com