Method for eliminating jaw bending of inner ring of hot-rolling finishing coil

A technology of jaws and inner rings, which is applied in the field of eliminating the bending of the inner rings of hot-rolled finishing coils, can solve the problems of low efficiency of manual cutting operations, increase of manual workload, and increase of manufacturing cycle, so as to improve operation efficiency, The effect of meeting quality requirements and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, the structure and working principle of the present invention will be further described in conjunction with the accompanying drawings.

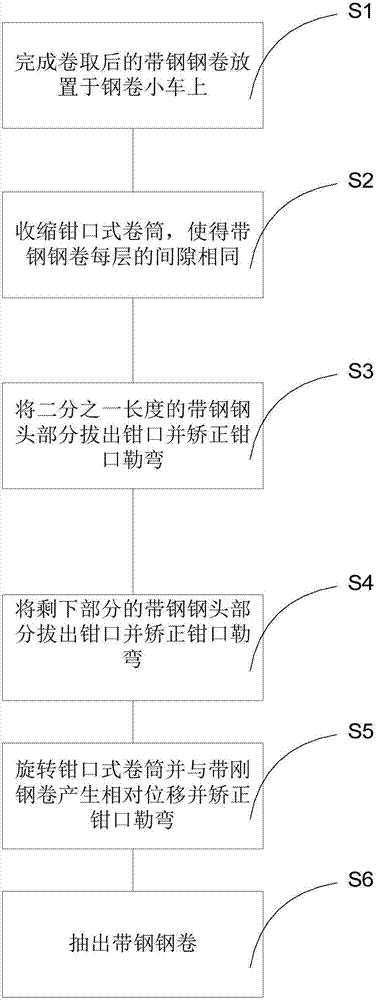

[0032] like figure 2 As shown, the method for bending the jaws of the inner ring of the hot-rolled finishing roll of the present invention includes:

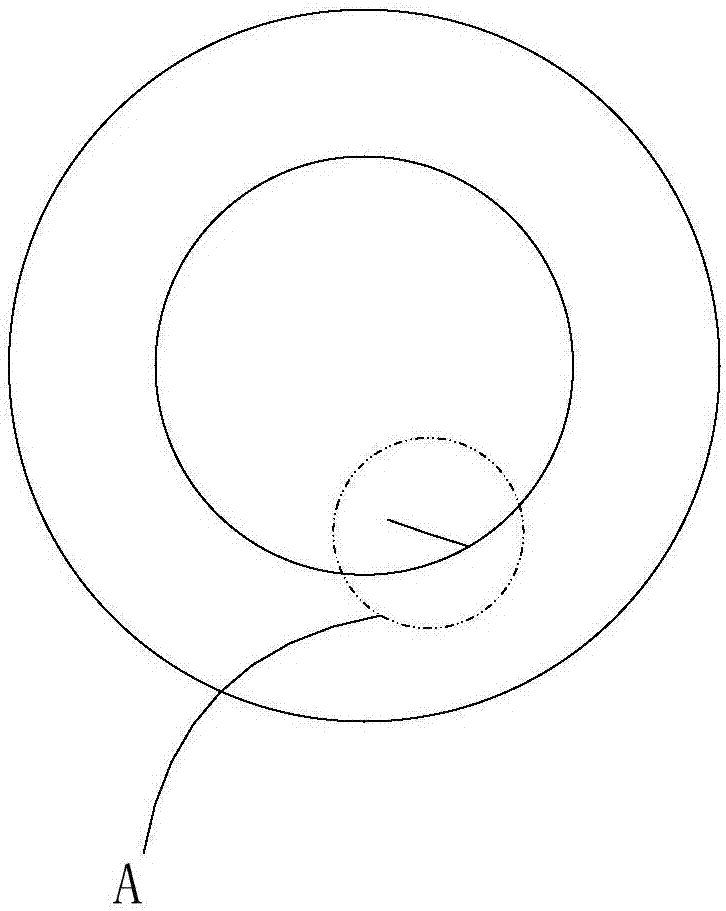

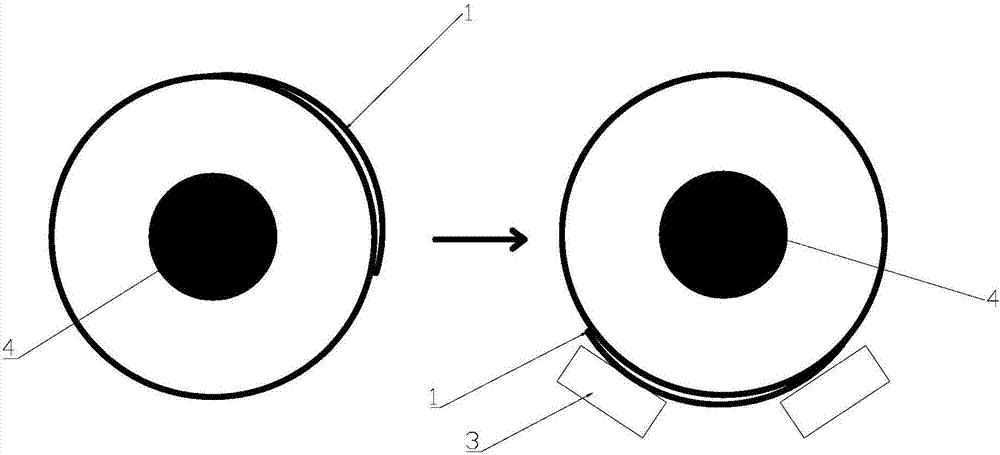

[0033] Step 1 S1, combined with the attached image 3 , first place the head of the strip steel in the jaws of the jaw type reel 4 to complete the coiling, and place the strip steel coil after coiling on the coil trolley so that the tail portion of the outer ring of the strip steel coil 1 Place it on the pallet 3 of the steel coil trolley;

[0034] Step 2 S2, shrinking the jaw type reel 4, so that the gap between each layer of the steel coil is the same;

[0035] Step 3 S3, combining Figure 4 As shown, 1 / 2 D2 of the strip head length D1 in the jaws 41 is pulled out from the jaws, and the extracted part is flattened.

[0036] Specifically, step three includes the following tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com