Post-tensioning chuck device

A chuck and rotary device technology, applied in positioning devices, boring/drilling devices, clamping, etc., can solve problems such as large bending deformation, easy vibration, and poor rigidity of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

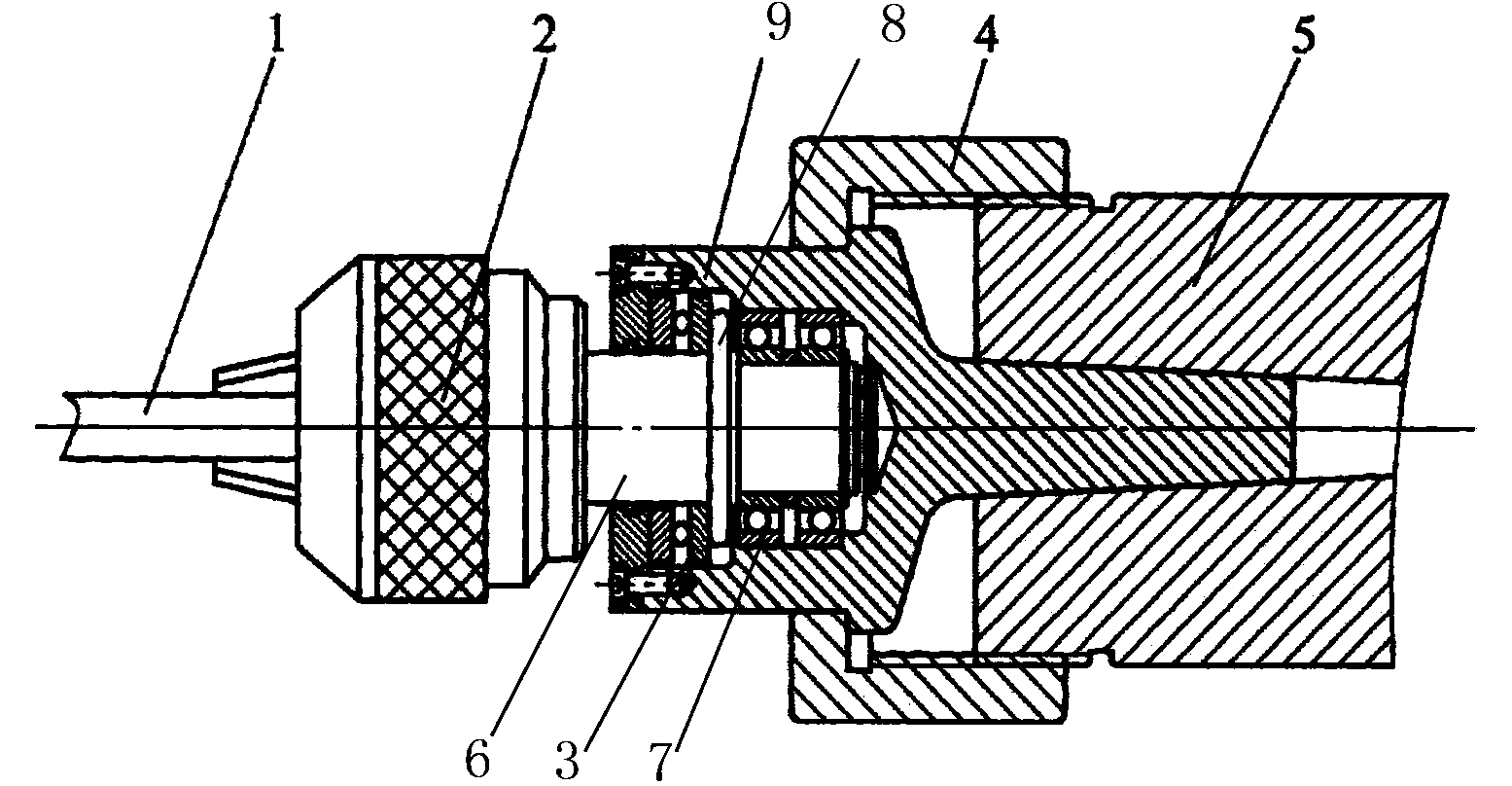

[0013] The back-pull chuck device of the present invention comprises a connection handle 9 and a connection nut 4 connected to the tailstock sleeve 5 of the machine tool, the tail of the connection handle 9 is a Morse taper handle, and the head is a cylinder with a groove. A plurality of bosses are arranged in the connecting handle 9 heads, and a boss is arranged on the outside of the connecting handle 9 heads, and a rotary device 3 is arranged in the connecting handle 9 heads, and an adjustable chuck assembly 2 is connected on the rotary device 3, which can The front end of the chuck assembly 2 is provided with a clamping claw, and a through hole is opened in the middle of the connecting nut 4, and the cylinder of the connecting handle 9 is arranged in the through hole, and one end of the connecting nut 4 is connected to the tailstock sleeve 5 through threads , the other end links to each other with the boss connecting handle 9 cylinder outsides. The rotary device 3 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com