Tread transfer ring of tire building machine

A tire building machine and transfer ring technology, applied in the field of rubber machinery, can solve the problems of locking cylinder failure, high maintenance cost, easy deformation of the gripping tread, and the locking cylinder structure cannot be locked, etc., so as to solve the problem of tread clamp The effect of holding deformation and local deviation of tread clamping, failure rate and maintenance cost is low, and repair and maintenance cost is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

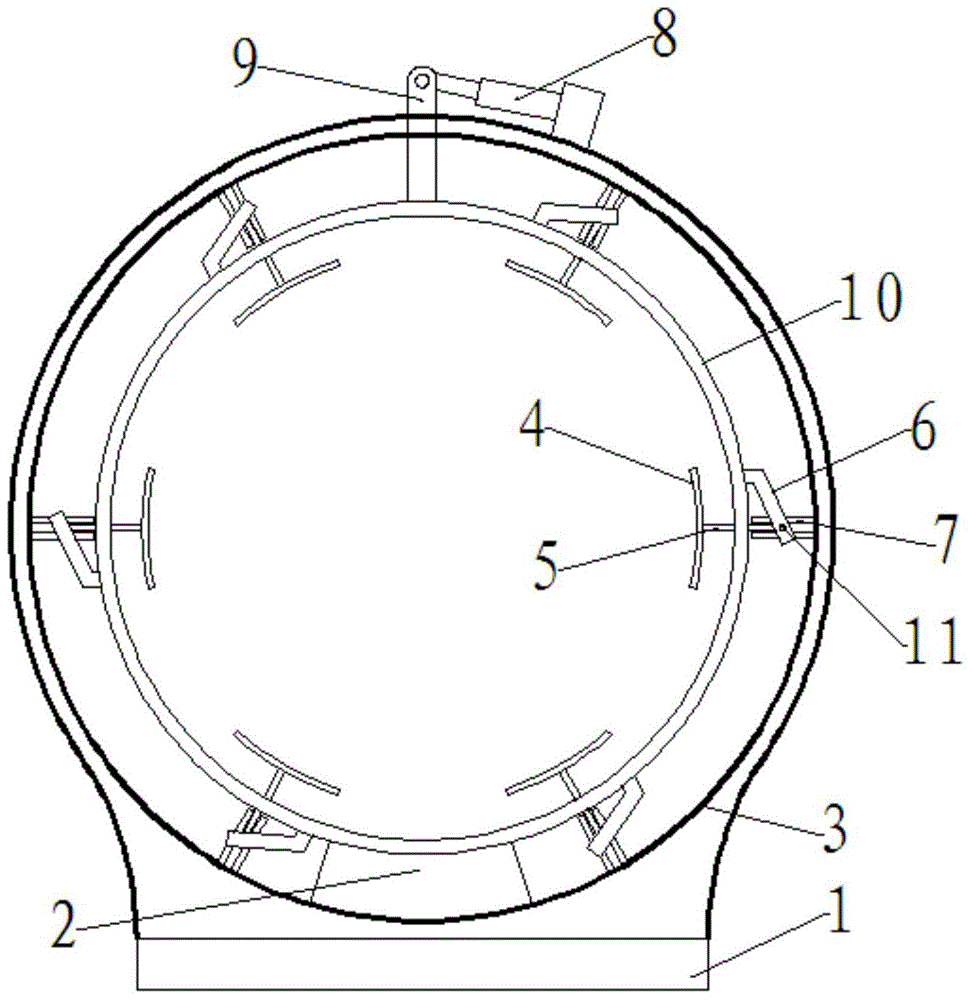

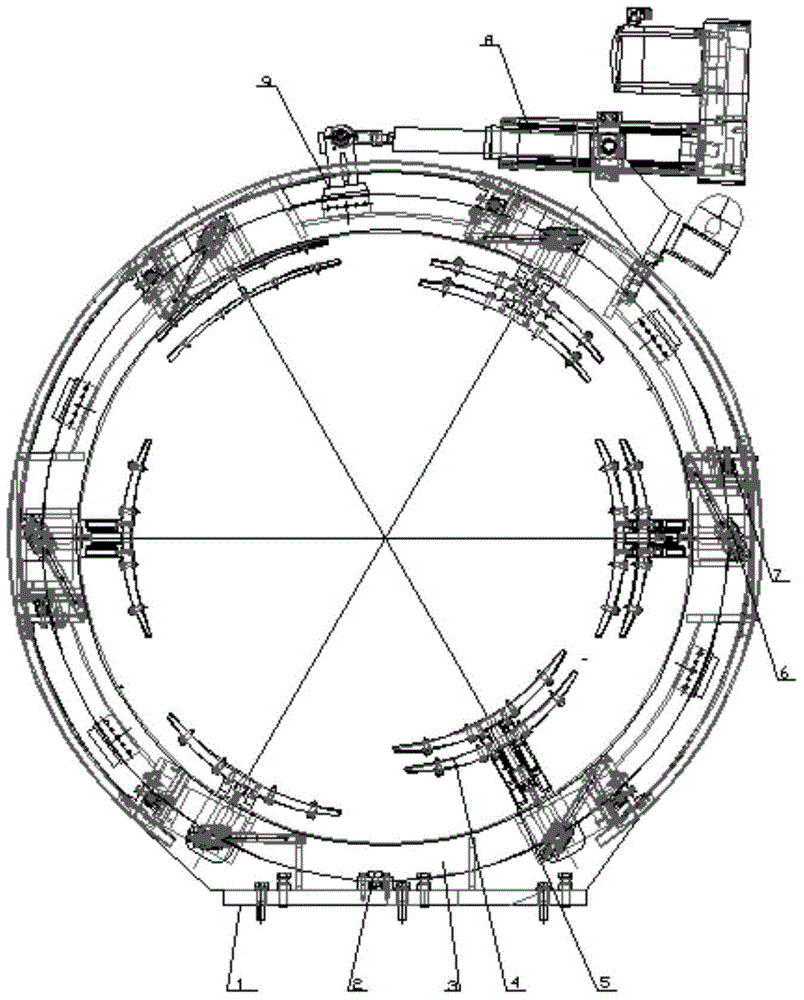

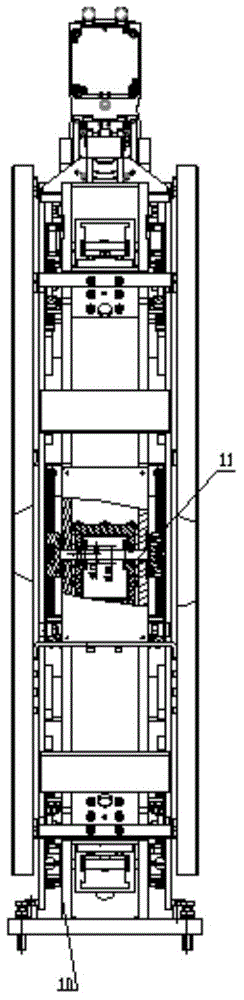

[0018] Referring to the accompanying drawings, a tread transfer ring of a tire building machine includes a base 1, a fixed plate 3, and several clamping claws 4. The fixed plate 3 is connected to the machine tool through the base 1 and slides reciprocatingly along the machine tool guide rail axially. The inside of the fixed disk 3 is connected with the drive disk 10 through the bearing 2, the drive disk 10 is connected with the telescopic structure 8 installed outside the fixed disk 3 through the bracket 9, and the clamping claw 4 is installed on the drive disk 10 On the inner ring, the clamping claw 4 cooperates with the wall of the driving disk 10 through the clamping claw bracket 5, and the clamping claw bracket 5 passes through the wall of the driving disk 10, and is installed on the fixed disk 3 through the shaft 11. The slide rail one 7 on the top is connected, and the shaft 11 is connected with the drive disk 10 through the slide rail two 6; the telescopic end of the tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com