Clamp and mechanical arm

A fixture and clamping technology, applied in metal processing machinery parts, clamping, clamping devices, etc., can solve problems such as excellent clamping function, and achieve the effects of simple structure, convenient operation and high use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

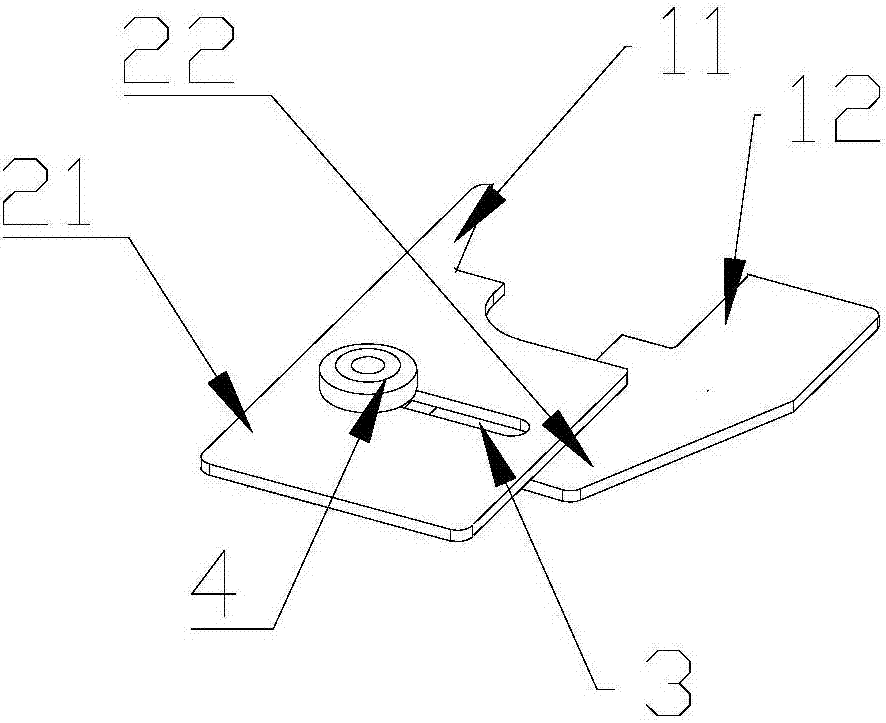

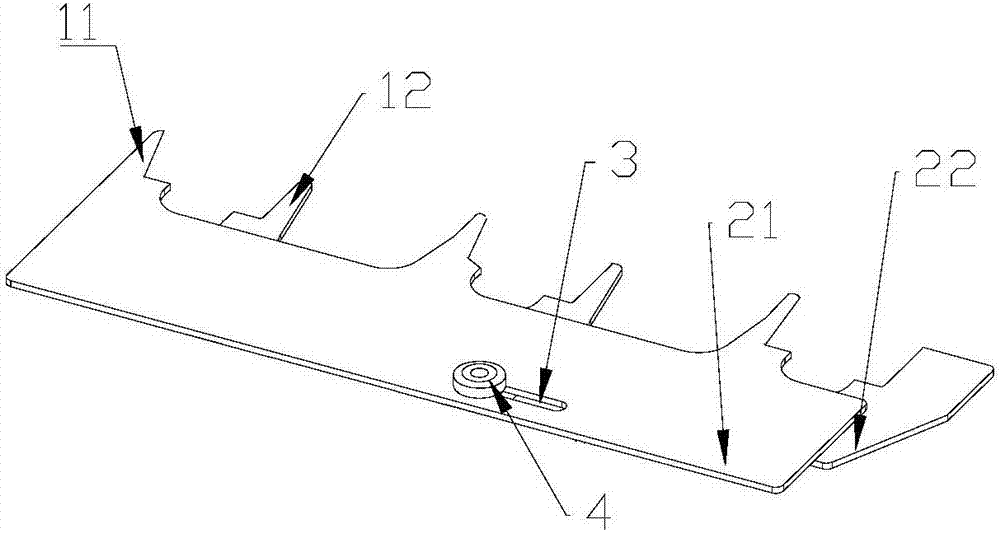

[0033] A kind of manipulator provided by the embodiment of the present invention, such as figure 1 As shown, including: clamping part and sliding part, wherein,

[0034] The clamping part includes an upper clamping area 11 and a lower clamping area 12 which are oppositely arranged;

[0035] The sliding part includes an upper sliding area 21 and a lower sliding area 22 arranged in layers, the upper sliding area 21 is connected to the upper clamping area 11, and the lower sliding area 22 is connected to the lower clamping area 12;

[0036] The upper sliding area 21 is provided with an adjustment hole 3, and the lower sliding area 22 is provided with a lower block, the lower block, the lower block is connected with a connecting rod, and the connecting rod passes through the adjustment hole 3 and is connected with a locking member 4, wherein , the connecting rod can slide along the adjusting hole 3, the locking part 4 can rotate relative to the connecting rod, and the rotation of...

Embodiment 2

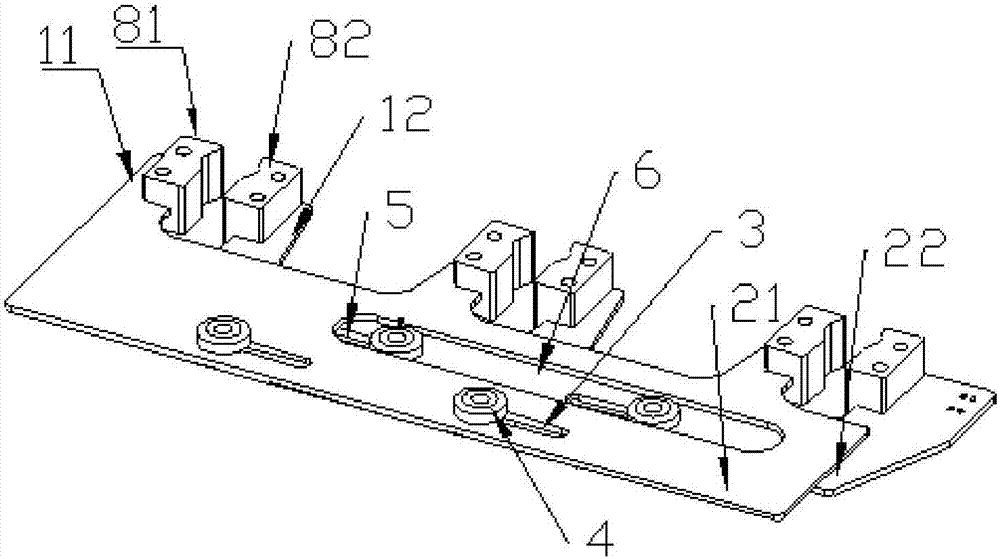

[0053] A manipulator provided in an embodiment of the present invention includes: a driving assembly and any clamp provided in Embodiment 1. like Figure 4 As shown, the drive assembly includes an upper drive assembly and a lower drive assembly, wherein the upper drive assembly is used to drive the movement of the upper sliding area 21 of the clamp, and the lower drive assembly is used to drive the movement of the lower slide area 22 of the clamp.

[0054] It should be noted, Figure 4 What is shown is only the situation that the manipulator includes a kind of clamp in the first embodiment.

[0055] In the embodiment of the present invention, the clamping part includes an upper clamping area 11 and a lower clamping area 12 arranged oppositely, and the workpiece to be processed is clamped between the upper clamping area 11 and the lower clamping area 12; The upper sliding area 21 and the lower sliding area 22, the upper sliding area 21 is connected with the upper clamping are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com