Pipeline fixing device for electrical and mechanical equipment

A technology for electromechanical equipment and fixtures, applied in the field of electromechanical equipment pipeline fixtures, can solve problems such as simple supporting devices, chaotic operating platforms, and influence on test results, and achieve the effect of eliminating influence and facilitating processing and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

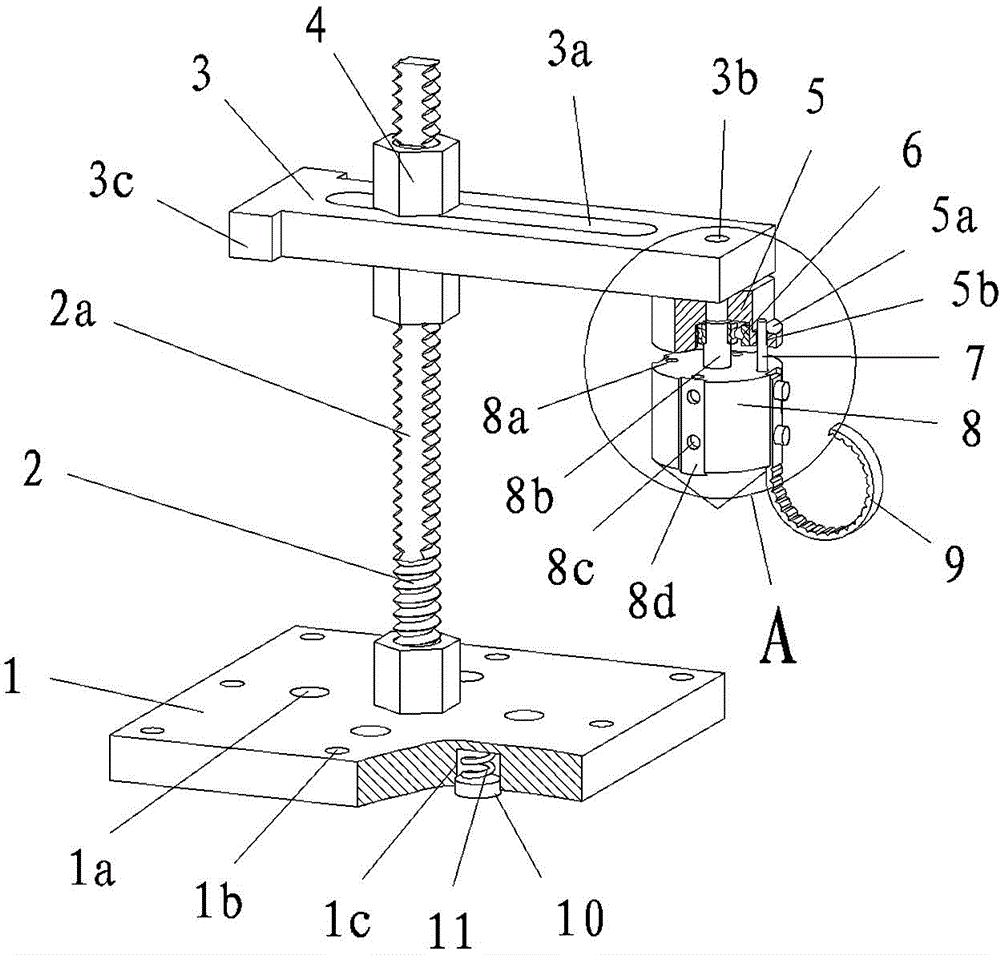

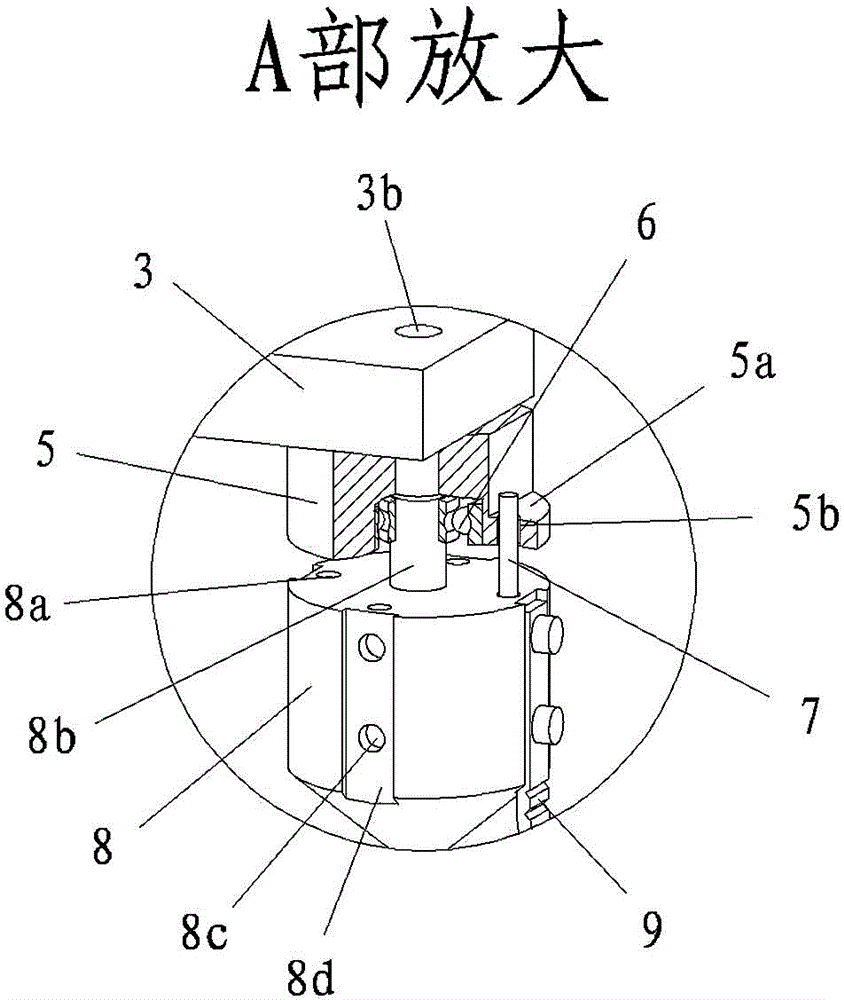

[0015] Such as figure 1 , figure 2 As shown, the electromechanical equipment pipeline fixing device provided by the present invention includes: a base 1, a column 2, a beam 3, a lock nut 4, a rotor seat 5, a rotor 8, and a hook 9. The lower end of the column 2 is connected to the base 1 , the upper side of the column 2 cooperates with the beam 3, and they are fixed and locked by the lock nut 4. The rotor base 5 is connected to one side of the beam 3, and the rotor base 5 is connected with a rotating and matched rotor 8. The rotor 8 is provided with a set of The hook 9 of fixed pipeline.

[0016] A set of fixing holes 1b are provided around the base 1 to fix the base, a set of column screw holes 1a are provided in the middle, and threads are provided on the column, and the lower end of the column 2 is connected with the column screw holes, and the column can be adjusted by connecting with different column screw holes In the working position, the rotating column can adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com