Automatic feeding and discharging device for parts

A technology of automatic loading and unloading and parts, which is applied in metal processing and other directions, can solve the problems of poor part consistency, low production efficiency, and high labor intensity, and achieve the effects of good part consistency, improved production efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

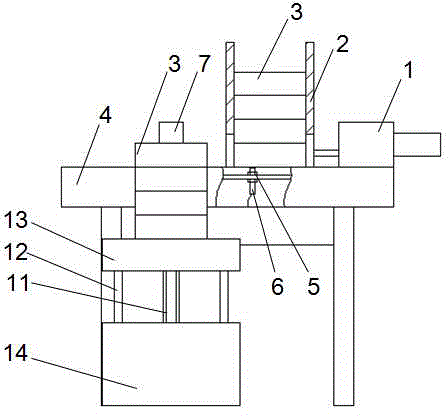

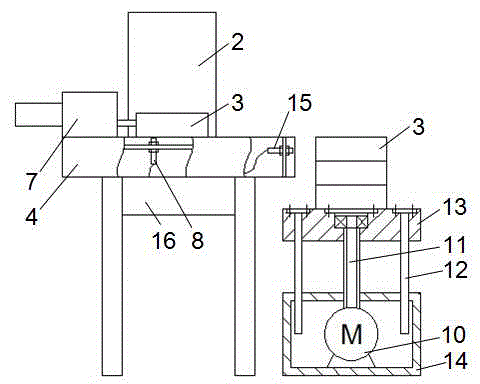

[0019] Such as figure 1 , 2 As shown, an automatic loading and unloading device for parts includes a workbench 4 and a storage chamber 2 for accommodating the material box 3. The upper surface of the workbench 4 is provided with a feed cylinder 1 and a discharge cylinder 7. The piston rod of the feed cylinder 1 will store The material box 3 at the bottom of the material chamber 2 is pushed to the stroke of the discharge cylinder 7, the piston rod of the discharge cylinder 7 pushes the material box 3 out of the workbench 4, and the outside of the slide-out side of the material box 3 of the workbench 4 is provided with a housing motor 10 The motor 10 drives the lead screw 11 to rotate up and down through the reducer, and the front end of the lead screw 11 is inserted into the inner ring of the bearing 9 in the lifting platform 13, driving the lifting platform 13 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com