Automatic feeding and discharging device

An automatic loading and unloading and feeding technology, which is applied in the field of machinery manufacturing and processing, can solve the problems of inability to simultaneously carry out bolt operation, high labor intensity of manual loading and unloading, and inability to perform other auxiliary operations, so as to improve labor production efficiency and reduce labor intensity , The effect of ensuring the continuity and reliability of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

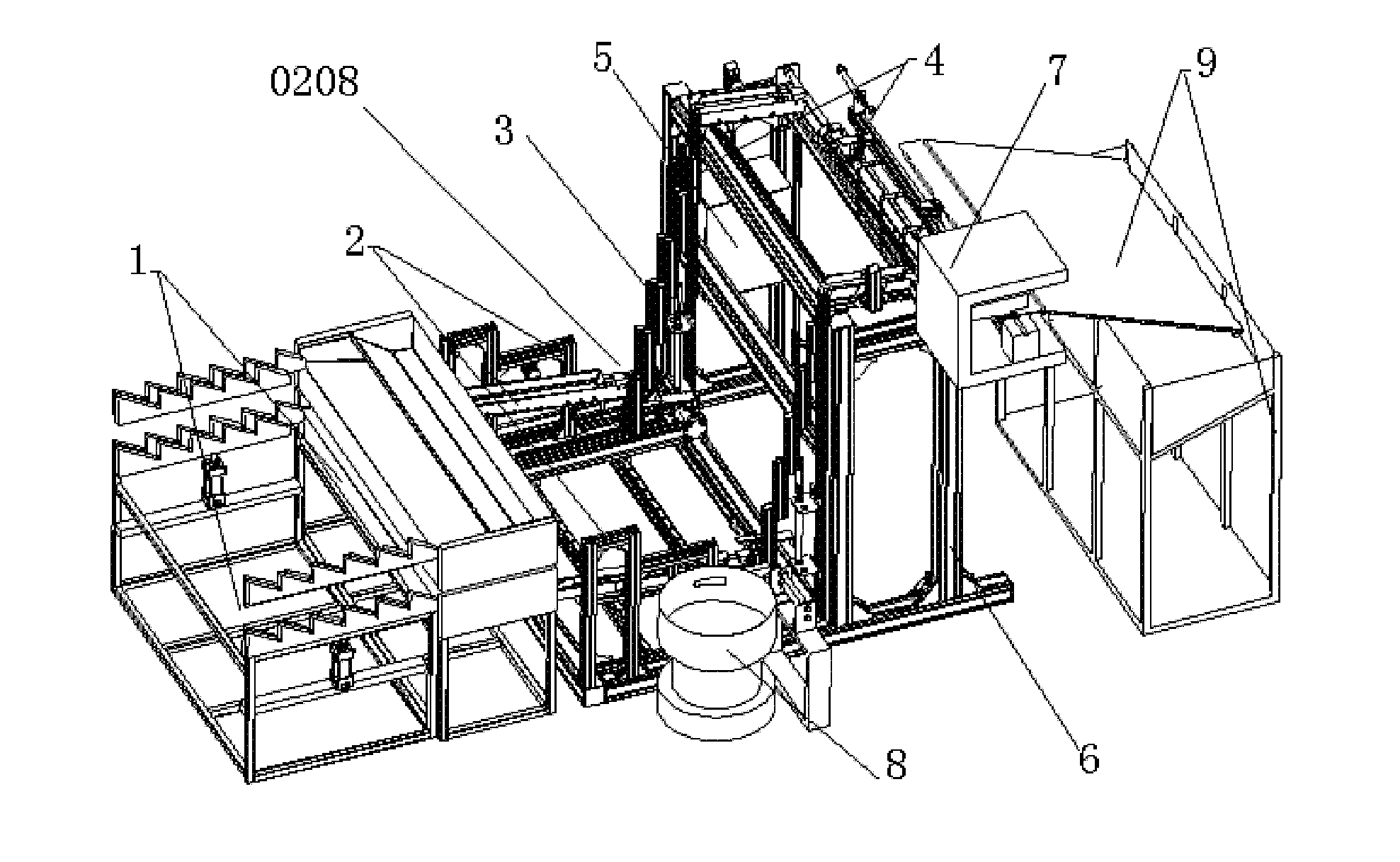

[0034] Such as Figure 1 to Figure 13 As shown, the automatic loading and unloading device is composed of a distribution mechanism 1, a blanking mechanism 9, and a transmission mechanism 0208 located between the distribution mechanism 1 and the blanking mechanism 9; the transmission mechanism 0208 includes a base 6, and 6 is equipped with a feeding mechanism 2, a lifting mechanism 3 and a feeding mechanism 4; the lifting mechanism 3 is arranged between the feeding mechanism 2 and the feeding mechanism 4; It is connected with the blanking mechanism 9.

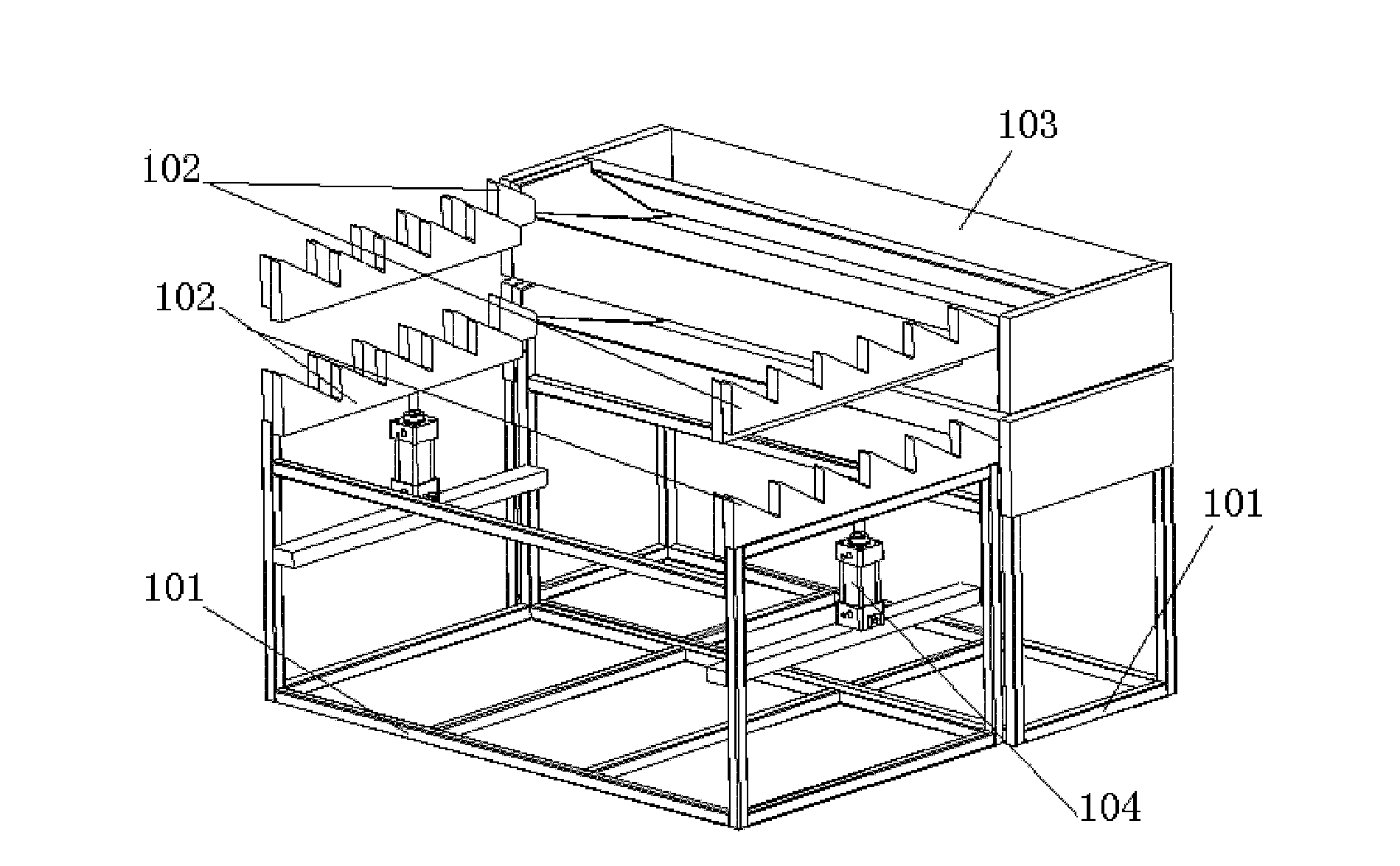

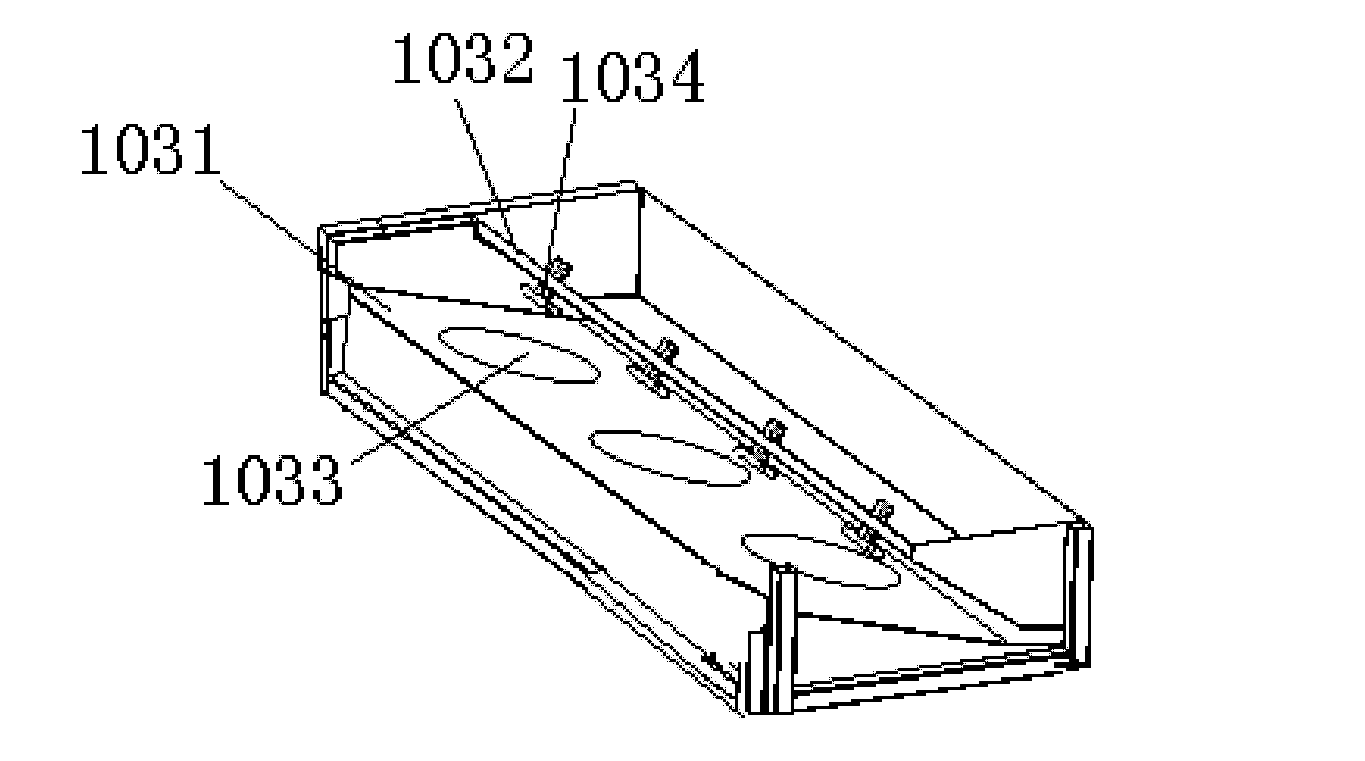

[0035]The material distributing mechanism includes a material distributing bracket 101, and a differential mechanism 102 for dispersing and driving the movement of the pipe material and a hopper 103 connected to the side of the differential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com