Lifting type charging tray feeding and discharging equipment

A lifting type and material tray technology, which is applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve the problems of occupying the space of processing equipment, unfavorable reduction of processing equipment cost, unfavorable processing equipment simplification, etc., to achieve saving Effects of saving space, labor and time, and eliminating waste of time and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

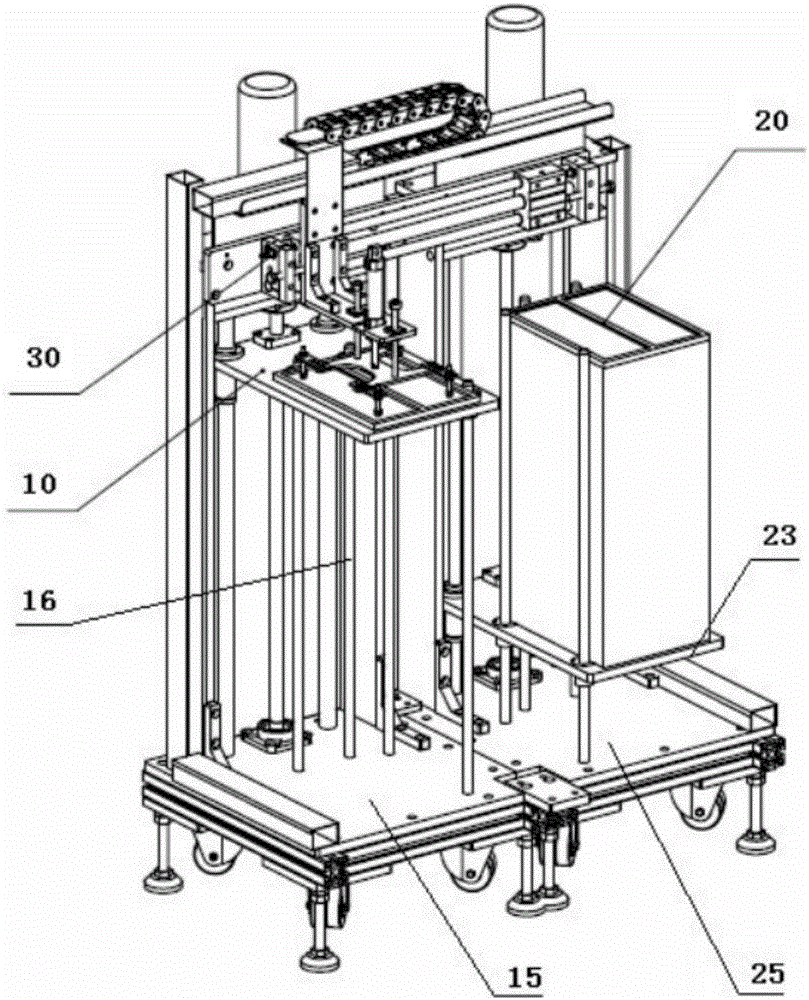

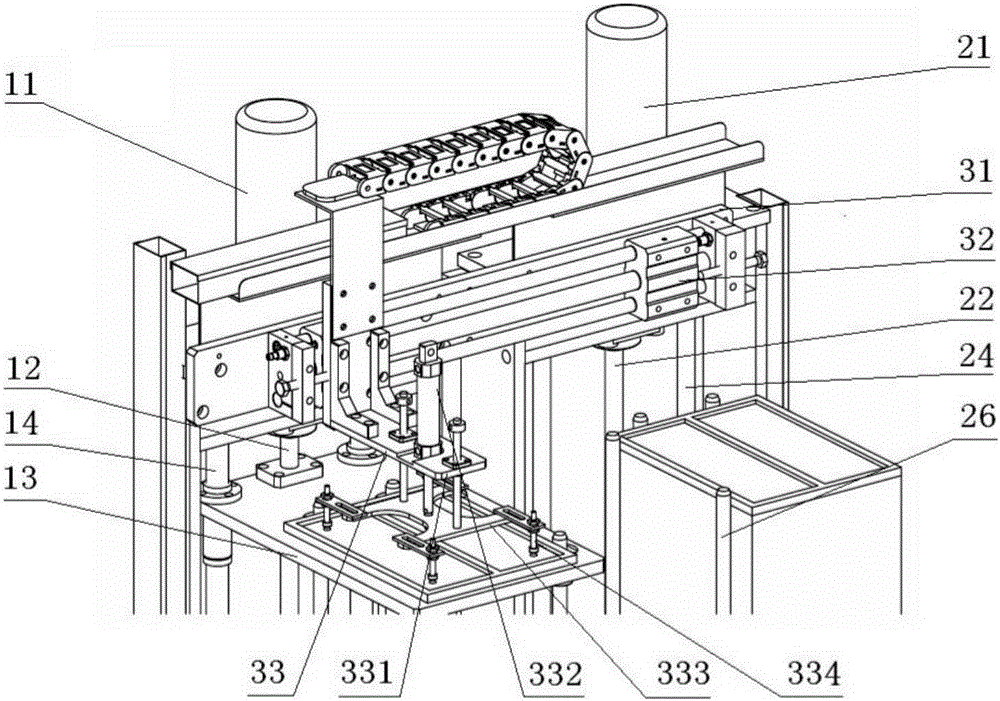

[0034] like figure 1 , a lifting type material tray loading and unloading equipment, including an empty material tray lifting mechanism 10, a blanking lifting mechanism 20, and a material moving mechanism 30.

[0035] combine figure 1 , figure 2 The empty tray lifting mechanism 10 includes a first lifting motor 11, a first screw rod 12 connected to the first lifting motor and arranged vertically, and a first support plate 13 screwed on the first screw rod and arranged horizontally and a first guide device 14 for guiding the lifting and lowering of the first pallet; the first pallet carries an empty material tray.

[0036] In the above-mentioned empty material tray lifting mechanism 10, the first guide device 14 includes a first guide sleeve installed on the first support plate 13 and a first guide column inserted in the first guide sleeve. The bottom end of the column is fixed on the first base 15, and the top end of the first guide column is fixed on the beam 31;

[0037] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com