Conveying belt type article storage and delivery device

A technology for conveying belts and articles, which is applied in the field of article storage and discharge devices, which can solve the problems of wasting internal storage space, sliding medicine boxes, and failure to reach the medicine, so as to improve space utilization, facilitate installation and use, and save shelves The effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

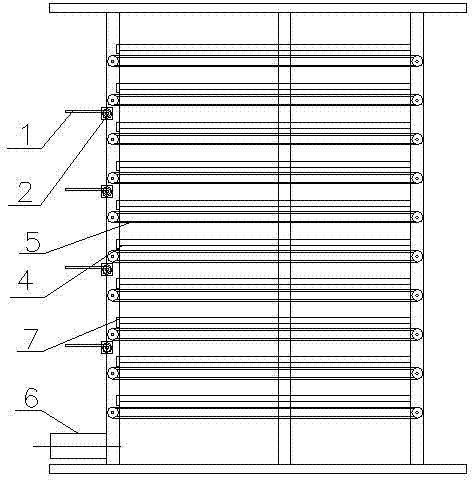

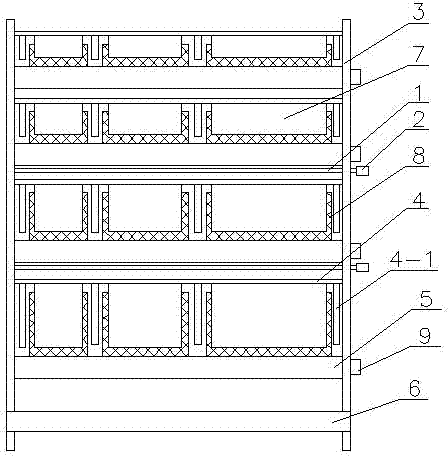

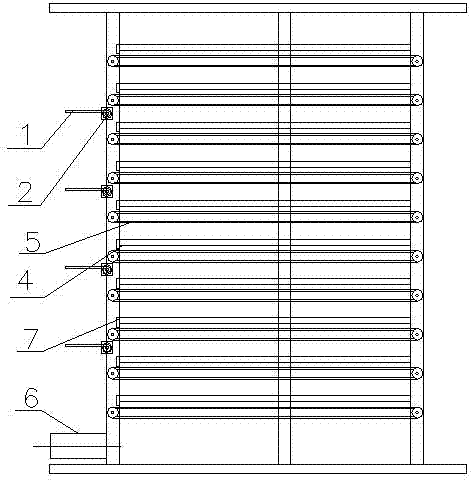

[0010] combine figure 1 , figure 2 , a kind of conveyer belt-type article storage out warehouse device of the present invention, comprises storage rack, several conveyer belts 5, clapboard 4, warehouse out controller 7, flap 1, flap power device 2, transmission belt power Device 9, belt conveyor 6, the transmission belt 5 is sequentially arranged on the frame body 3 of the storage rack from top to bottom, two adjacent transmission belts are parallel to each other, and each transmission belt is connected to the transmission belt power device 9, the top of each conveyor belt is provided with partitions 4, and the partitions divide the conveyor belt 5 into several mutually independent storage passages according to the size of the storage 8, and each storage passage is Parallel to the forward direction of the conveyor belt, the output end of each storage channel is equipped with an openable warehouse-out controller 7, and the flap 1 is set at the outlet end of the conveyor belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com