Loading and unloading device and method for ultrathin plate glass grinding step

A technology of flat glass and ultra-thin glass, which is applied in the direction of machine tools suitable for grinding workpiece planes, optical surface grinders, and parts of grinding machine tools. Deformation and other problems, achieve good fluid permeability, maintain flatness, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

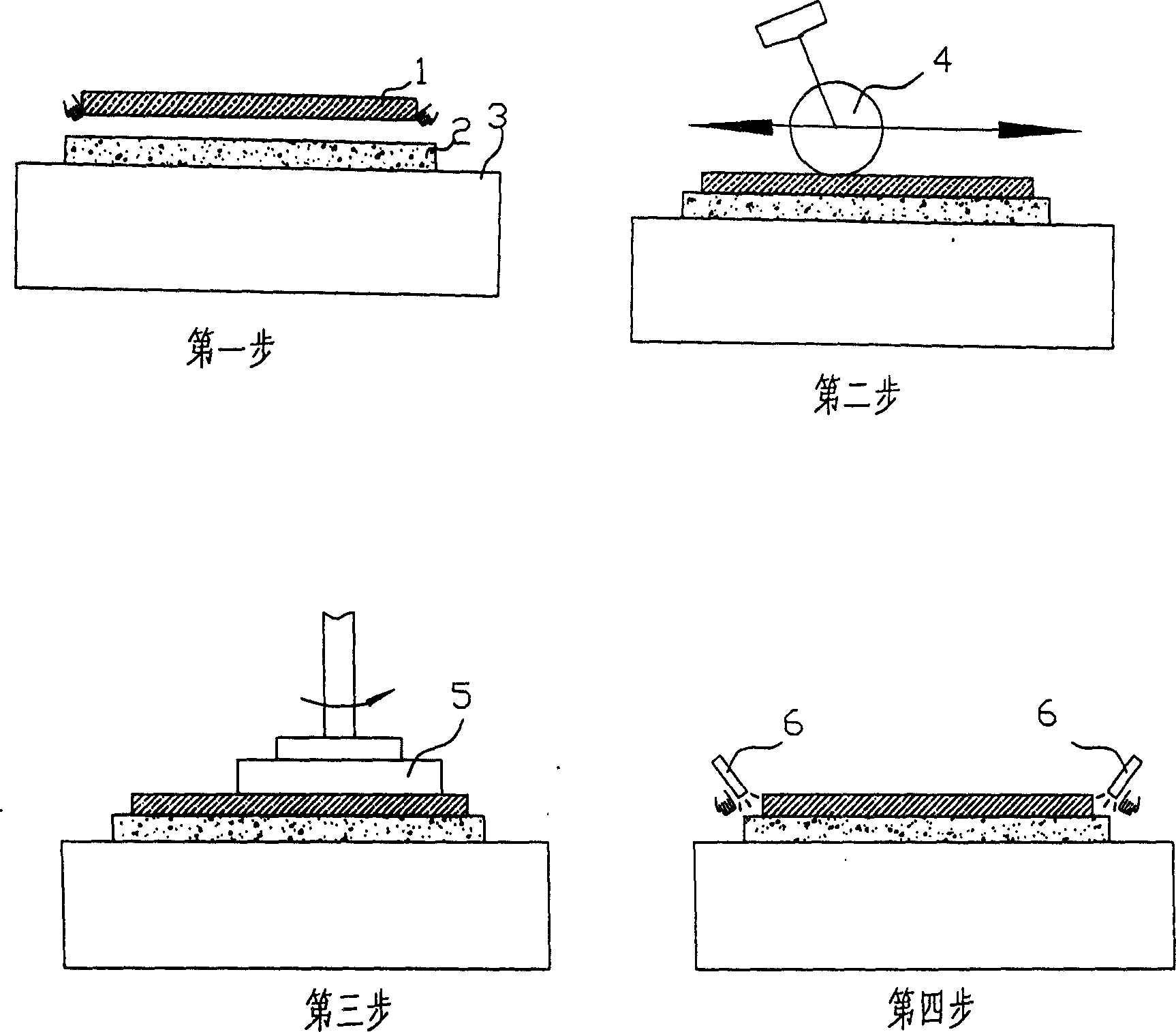

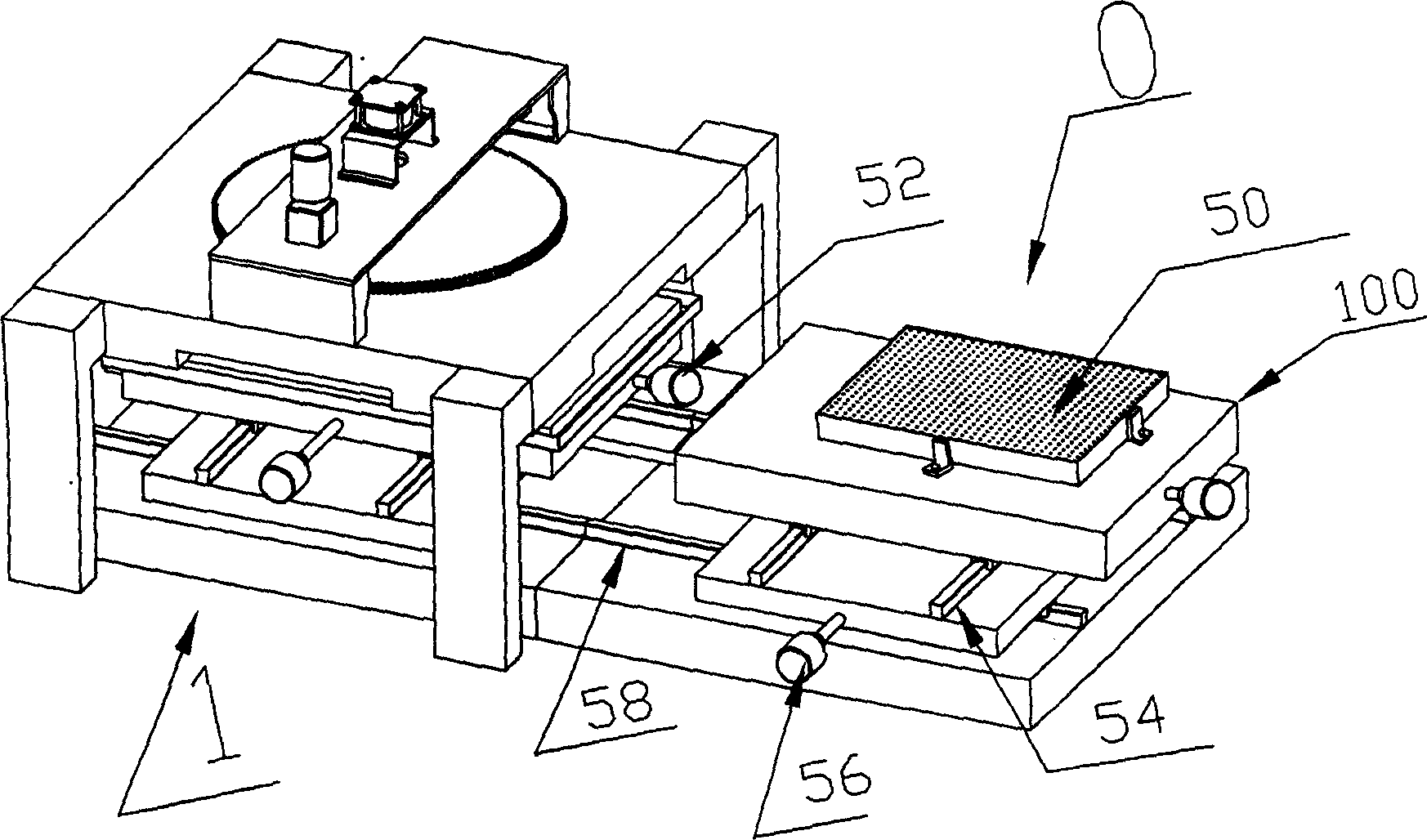

[0020] Such as image 3 , 4 , 5, the present invention is used in the loading and unloading device of flat ultra-thin glass grinding process, including the workbench mechanism that has air holes on the surface and can realize vacuum adsorption and pressure air suspension for flat glass substrates, and utilizes servo motors to drive vacuum adsorption and The workbench mechanism of pressure air suspension realizes the device for loading and unloading the flat glass substrate. In the workbench mechanism of vacuum adsorption and pressure air suspension, there is a loose microporous rigid material for carrying the flat glass substrate between the workbench and the flat glass. Comes as a spacer.

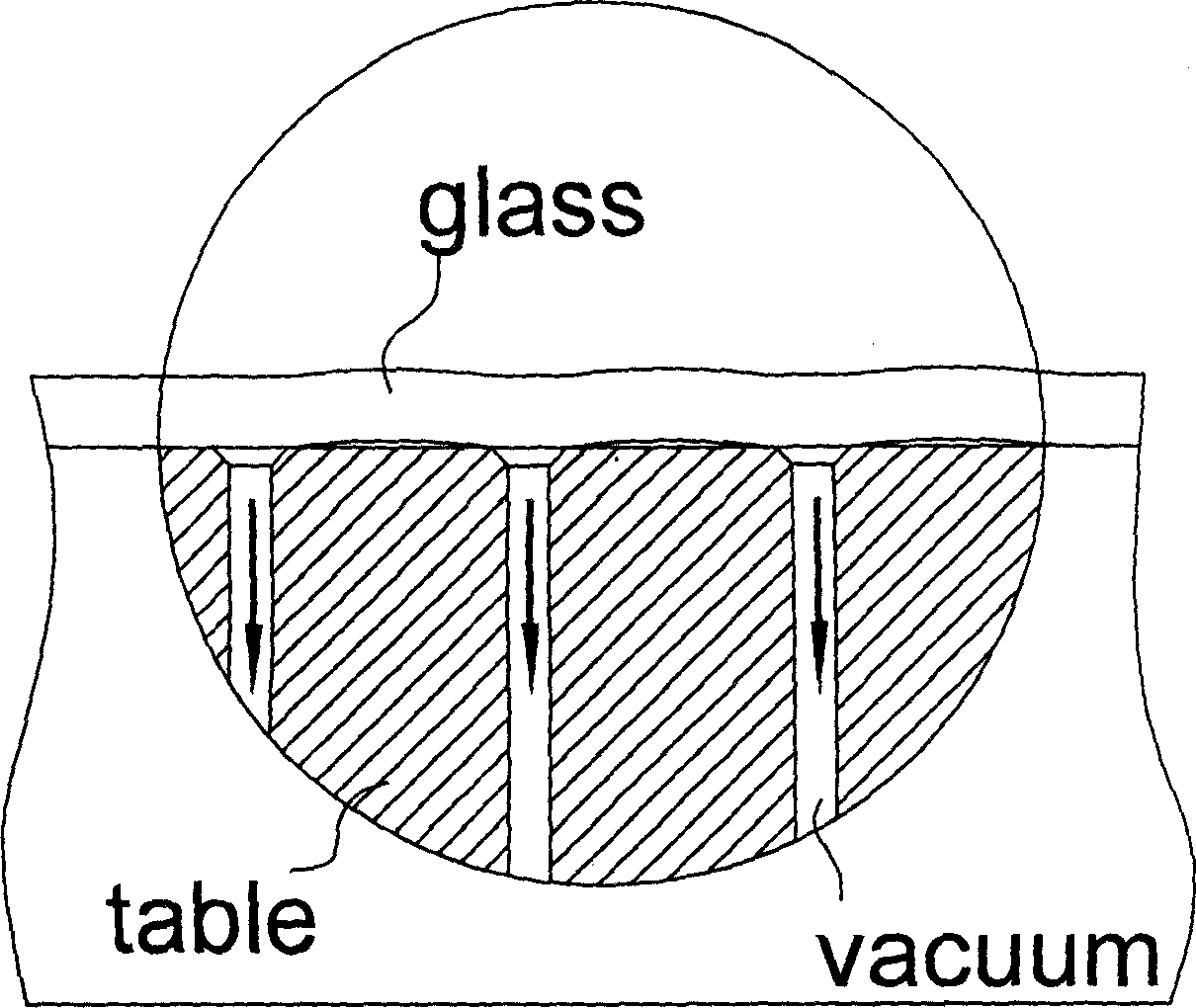

[0021] as attached Figure 5 As shown, the loose microporous rigid material is made of microporous ceramics with a loose structure and good fluid permeability. The ceramic pad is fixed on the workbench, and a certain number of pores are prefabricated on the workbench, which are opened in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com