Automatic control system of efficient handing operation of container crane

The technology of a container crane and an automatic control system is applied in the control of the crane spreader and in the field of operation and production of the container crane, and can solve the problem that the driver is prone to fatigue and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the specific implementation method of the high-efficiency operation automatic control system for container cranes of the present invention will be described in detail with reference to the accompanying drawings.

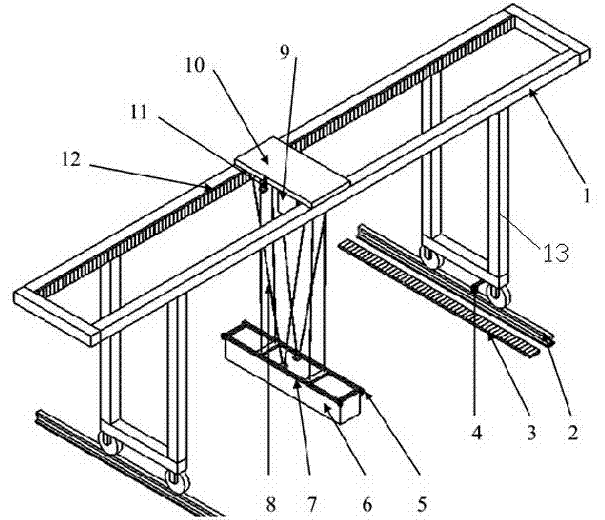

[0020] Such as figure 1 As shown, the overall composition of the present invention has: crane cart 13, cart running track 2, trolley running track 1, crane cart 13 moves linearly along cart track 2 under the control of cart operation control mechanism, trolley The running track 1 is fixed above the crane trolley 13, and the trolley 10 is matched on the trolley running track 1, and the trolley 10 makes a linear motion along the trolley running track 1 on the main girder of the container crane under the control of the trolley running control mechanism. Below 10, the anti-sway wire rope 8 hanger 7 is passed, and the anti-sway wire rope 8 is connected to the output end of the hoisting operation control mechanism of the hanger.

[0021] On one side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com