Crystal blank automatic polishing system

A blank and crystal technology, applied in the field of grinding and polishing of crystal products, can solve the problems of difficult transportation and manufacturing, high requirements on machine manufacturing precision, complicated and tedious mechanism actions, etc., to simplify the complexity of mechanism actions and ensure the quality of grinding and polishing. , easy to manufacture and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

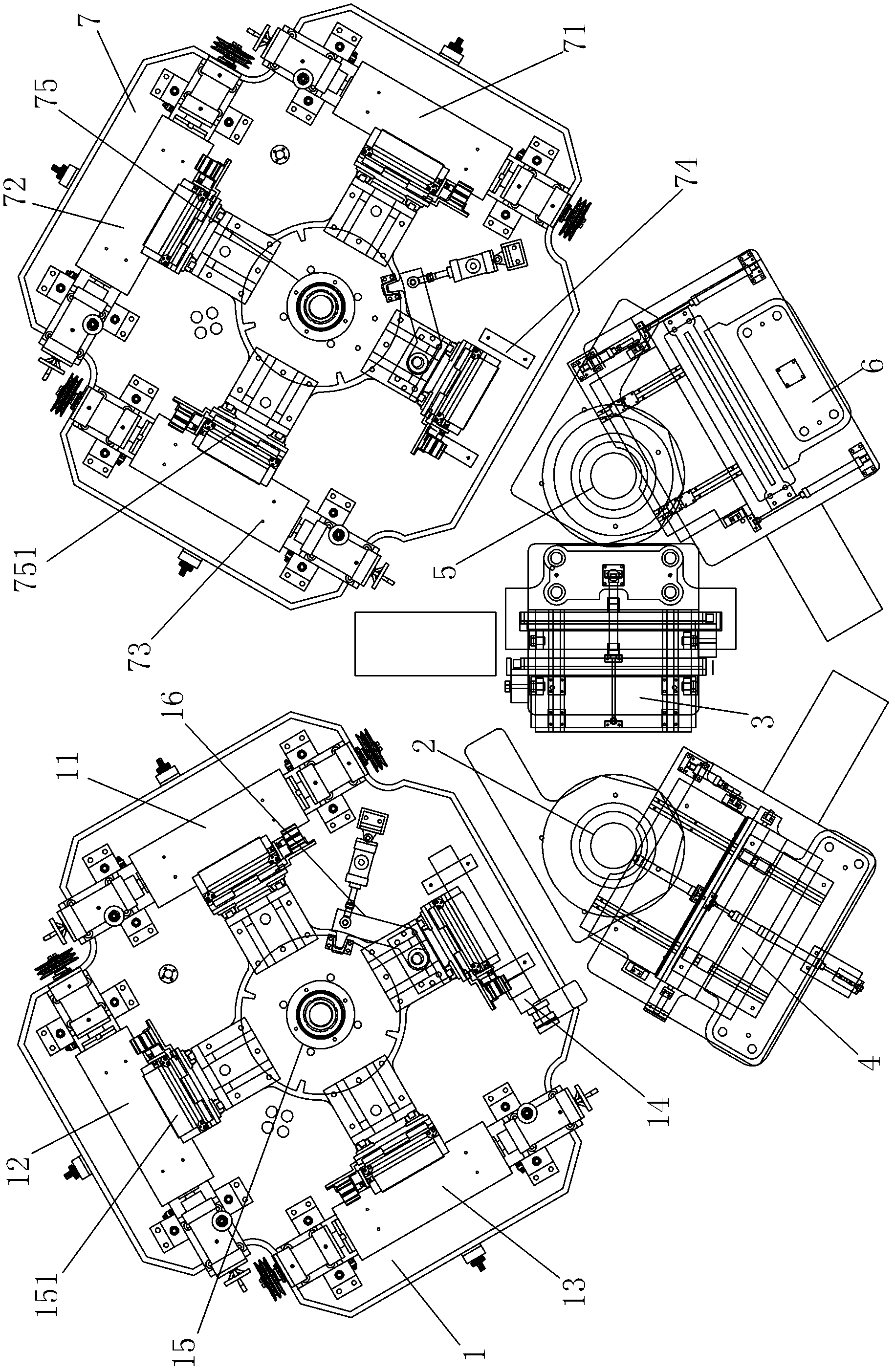

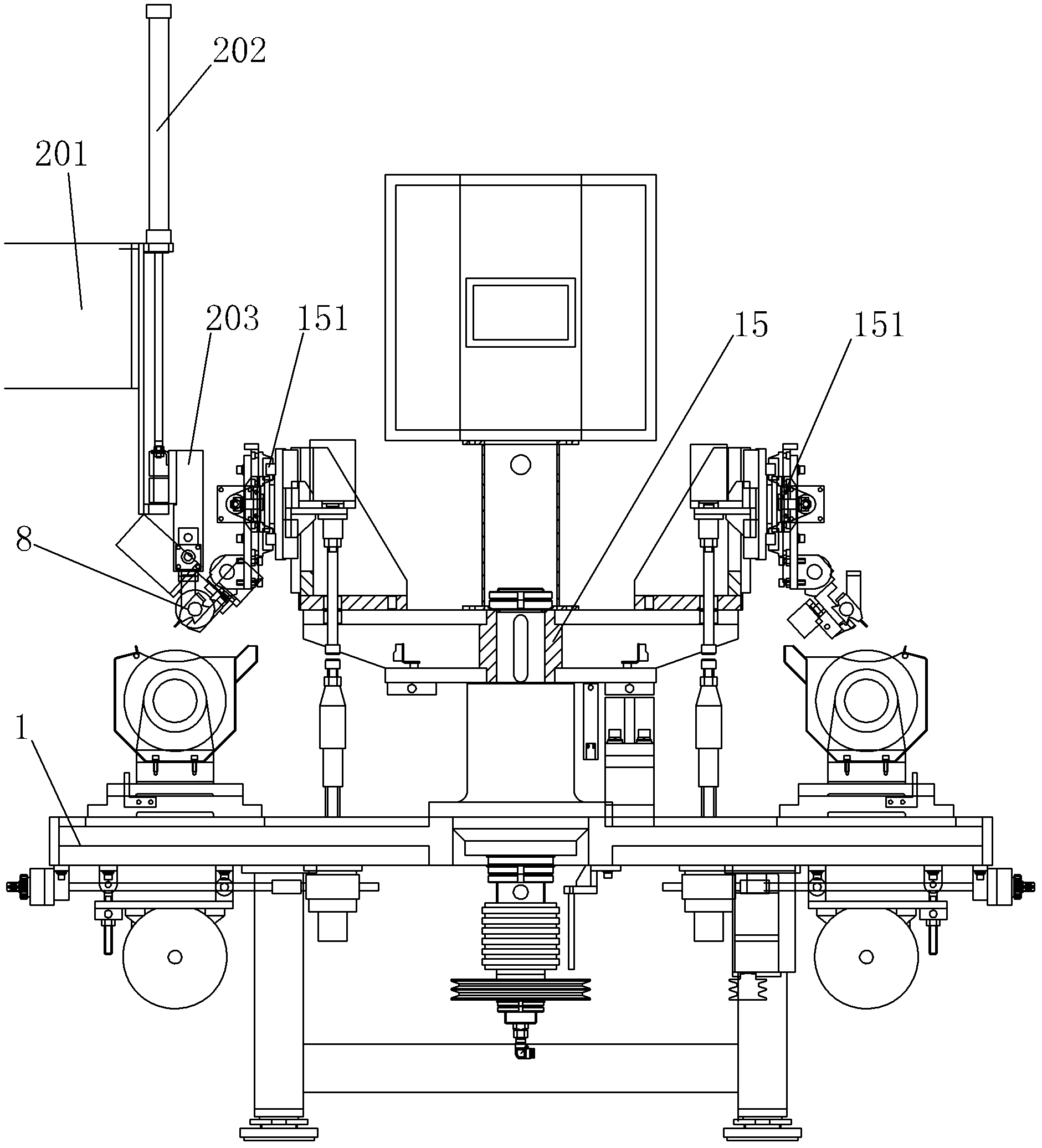

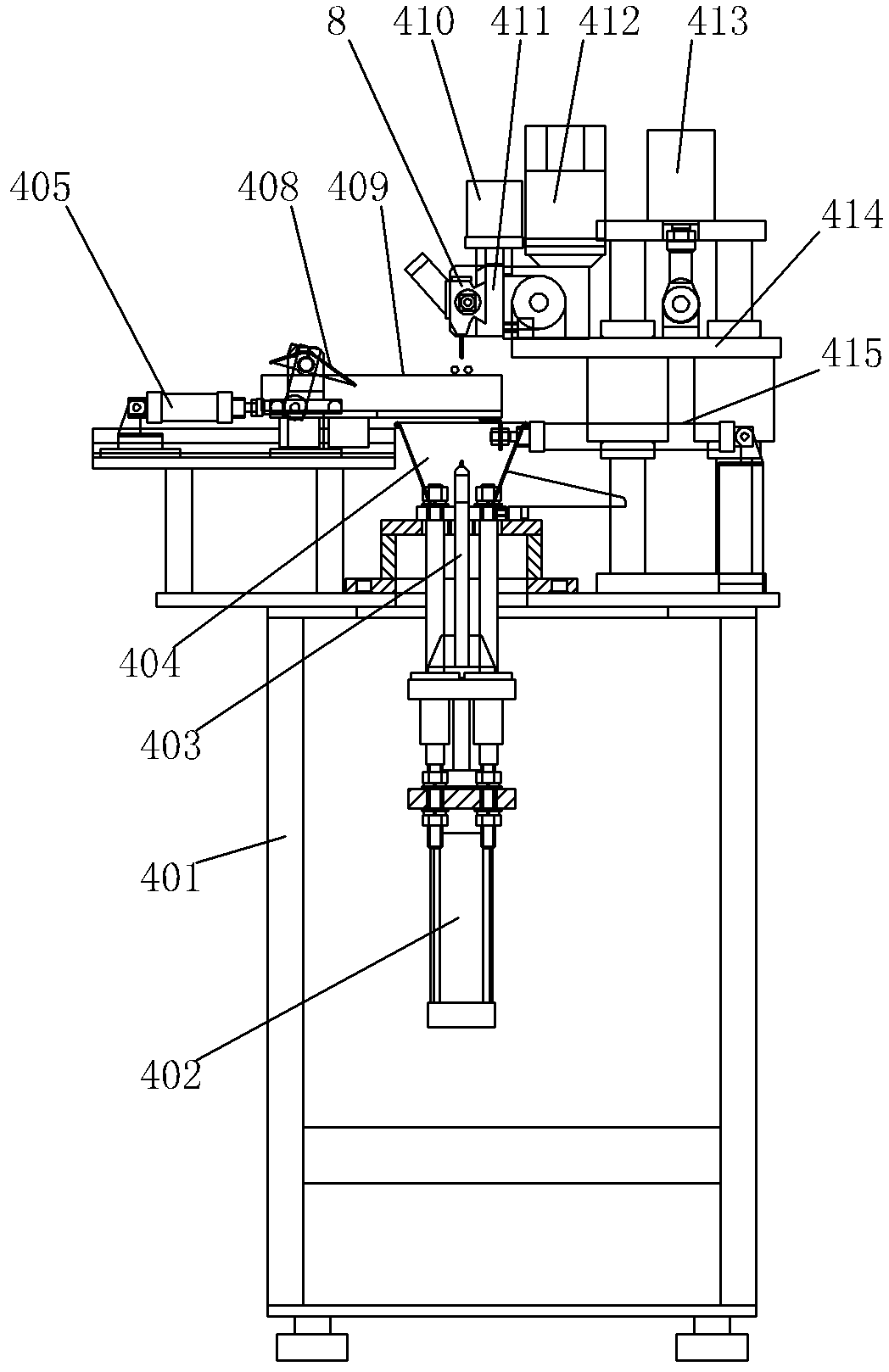

[0030] Such as figure 1 , figure 2 The shown automatic grinding and polishing system for crystal blanks is used to process crystal blanks with two hemispherical slopes, including: rotating the first rotating frame 15 arranged on the grinding and polishing frame 1, surrounding the first rotating frame 15 An upper hemisphere grinding station 11 for grinding the upper hemisphere of the crystal blank, two upper hemisphere polishing stations 12, 13 and a waiting station 14 for polishing the upper hemisphere of the crystal blank are provided, The first rotary frame 15 can rotate and be positioned by the rotary positioning mechanism 16, on which four machine heads 151 capable of installing the clamp 8 are provided; The frame 75 is provided with a lower hemisphere grinding station 71 for grinding the lower hemisphere of the crystal blank, two lower hemisphere polishing stations 72, 73 for polishing the lower hemisphere of the crystal blank and a waiting station 74, the second rotat...

Embodiment 2

[0033] Such as Figure 12The shown automatic grinding and polishing system for crystal blanks is used to process crystal blanks with only one hemispherical slope, including: a first rotating frame 15, and a device for grinding and processing the crystal blanks is arranged around the first rotating frame 15. The grinding station 11 and a polishing station 12, 13 for polishing the crystal blank, the first rotating frame 15 can rotate and be positioned and is provided with four heads 151; the loading station 4 is provided with a The feeding mechanism that the crystal blank is fixed on the clamp; the blanking station 6 is provided with a blanking mechanism that can detach the crystal blank from the clamp; The transfer mechanism 2 that transfers between the material station 4, the blanking station 6 and the head 151 on the first rotating frame 15; wherein, the grinding stations 11, 12 are provided with a grinding mechanism, and the The polishing station 13 is provided with a polis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com