Manipulator grinding system

A technology of manipulator grinding and manipulator arm, which is applied in manipulators, grinding machines, grinding racks, etc., can solve the problems of waste of manpower and material resources, single function, and insufficient compact structure, and achieve improved work efficiency, high degree of automation, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present application will be described in detail below in conjunction with specific embodiments and accompanying drawings.

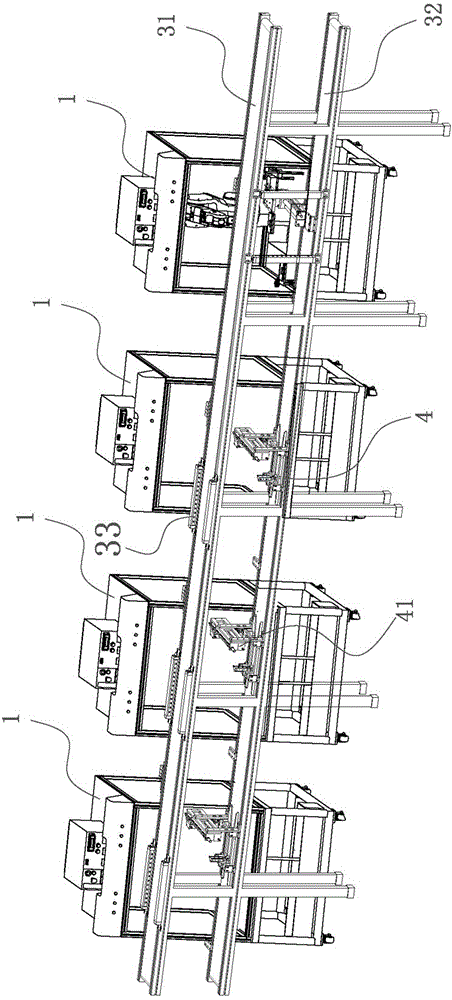

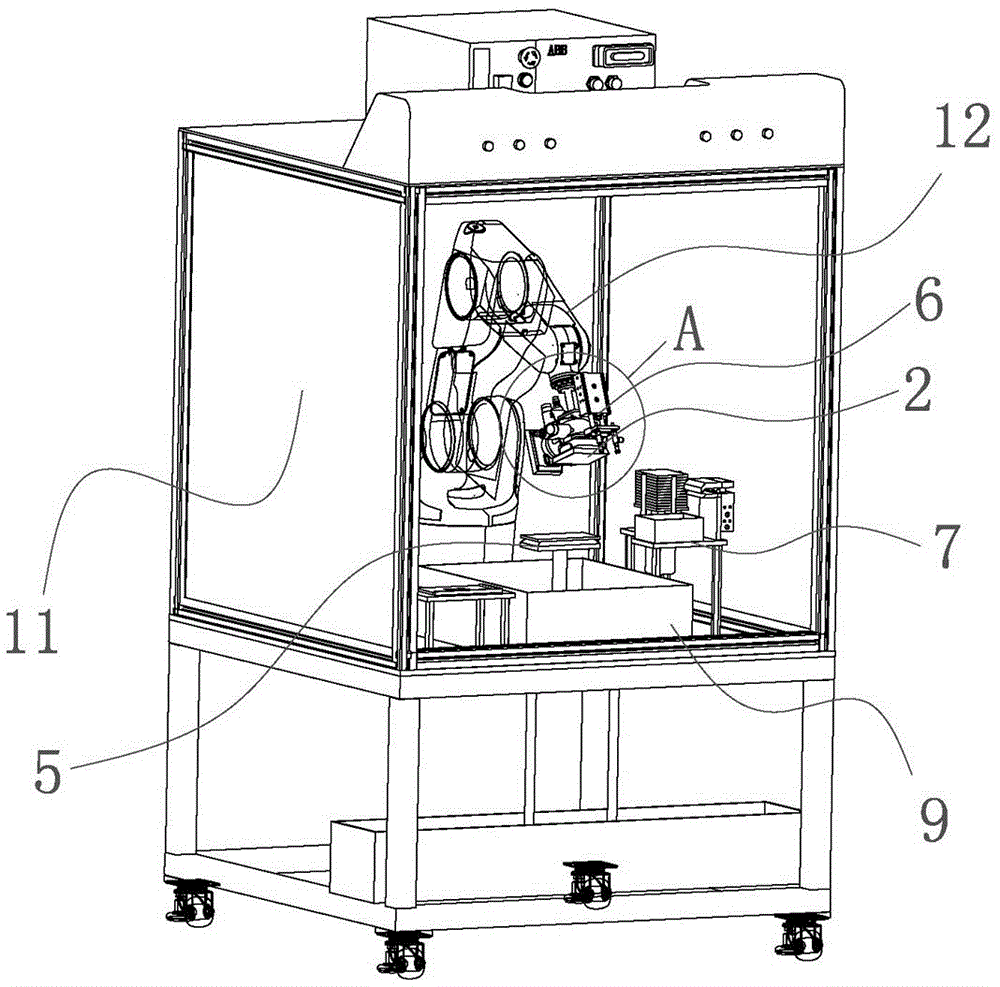

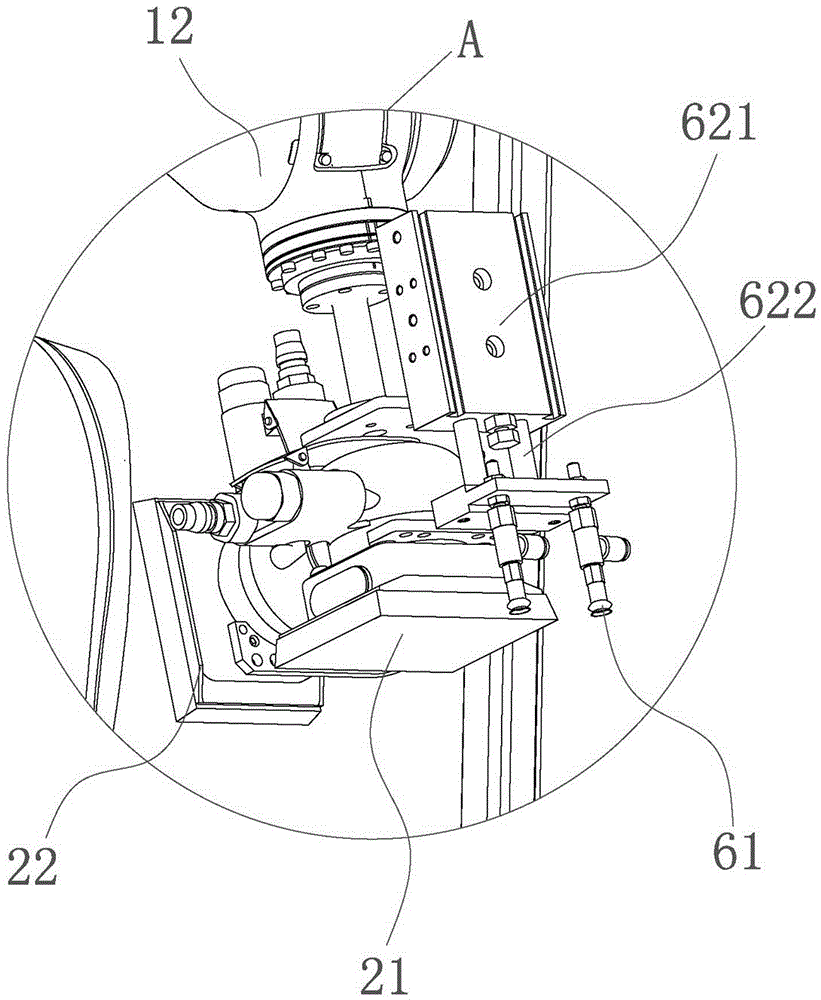

[0042] A kind of manipulator grinding system of the present embodiment, such as Figure 1 to Figure 9 As shown, it includes a grinding robot device 1 and a conveyor belt. The grinding robot device 1 includes a housing 11, a mechanical arm 12, a grinding tool installed at the end of the mechanical arm 12, and a grinding table 5 for fixing a product; the grinding tool includes a first grinding tool Tool 21 and the second grinding tool 22, the mechanical arm 12 is provided with the first installation part and the second installation part that are arranged at 90 degrees, the first grinding tool 21 is installed on the first installation part, and the second grinding tool 22 is installed on the second installation part. Installation part; Conveyor belt comprises first conveyer belt 31 and the second conveyer belt 32 that move toward opposite, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com