Grinding machine for bearing rings

A bearing ring and grinding technology, which is applied to the parts of grinding machine tools, grinding machines, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve problems such as wear, contact, and grinding wheel damage, and achieve good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

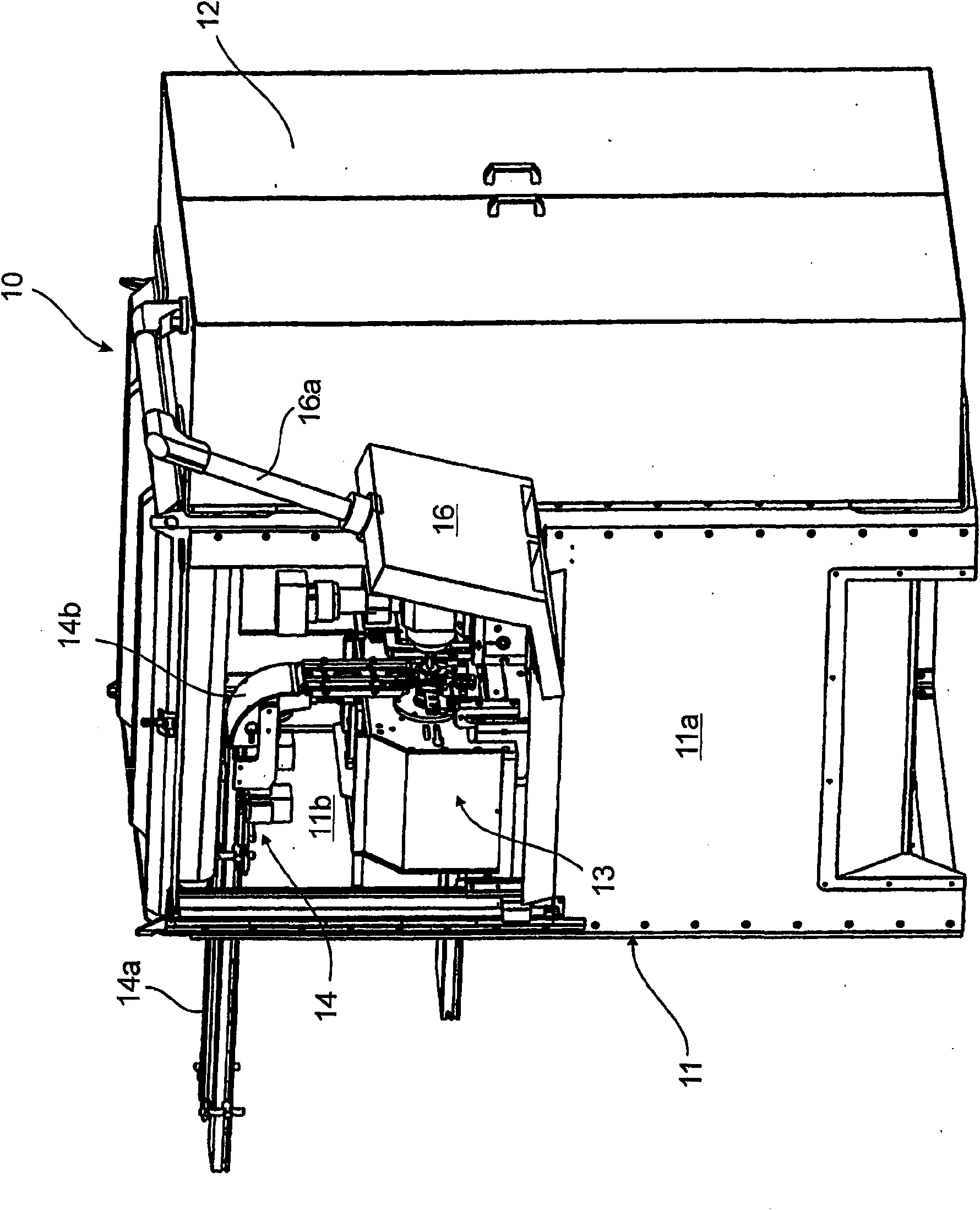

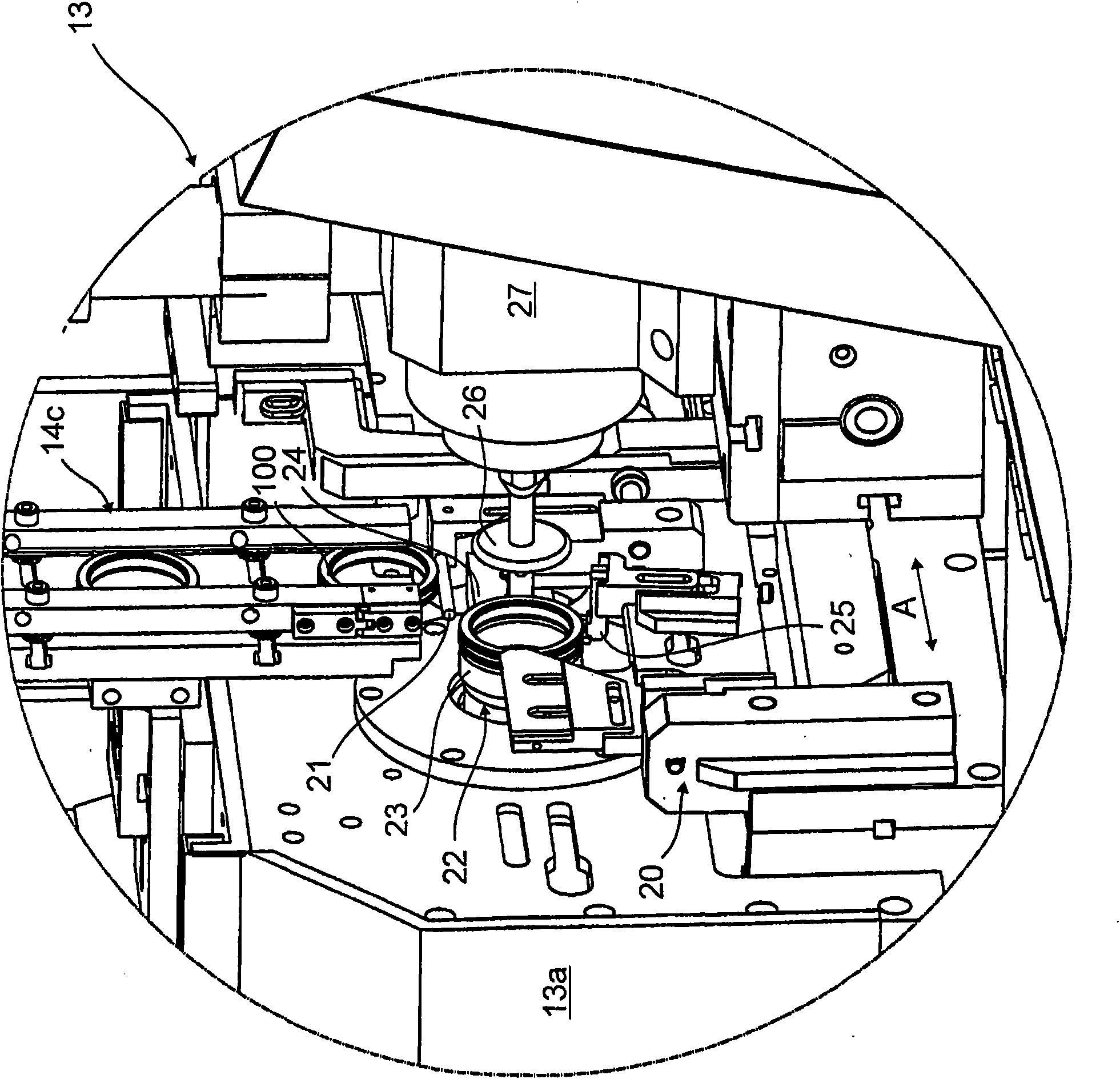

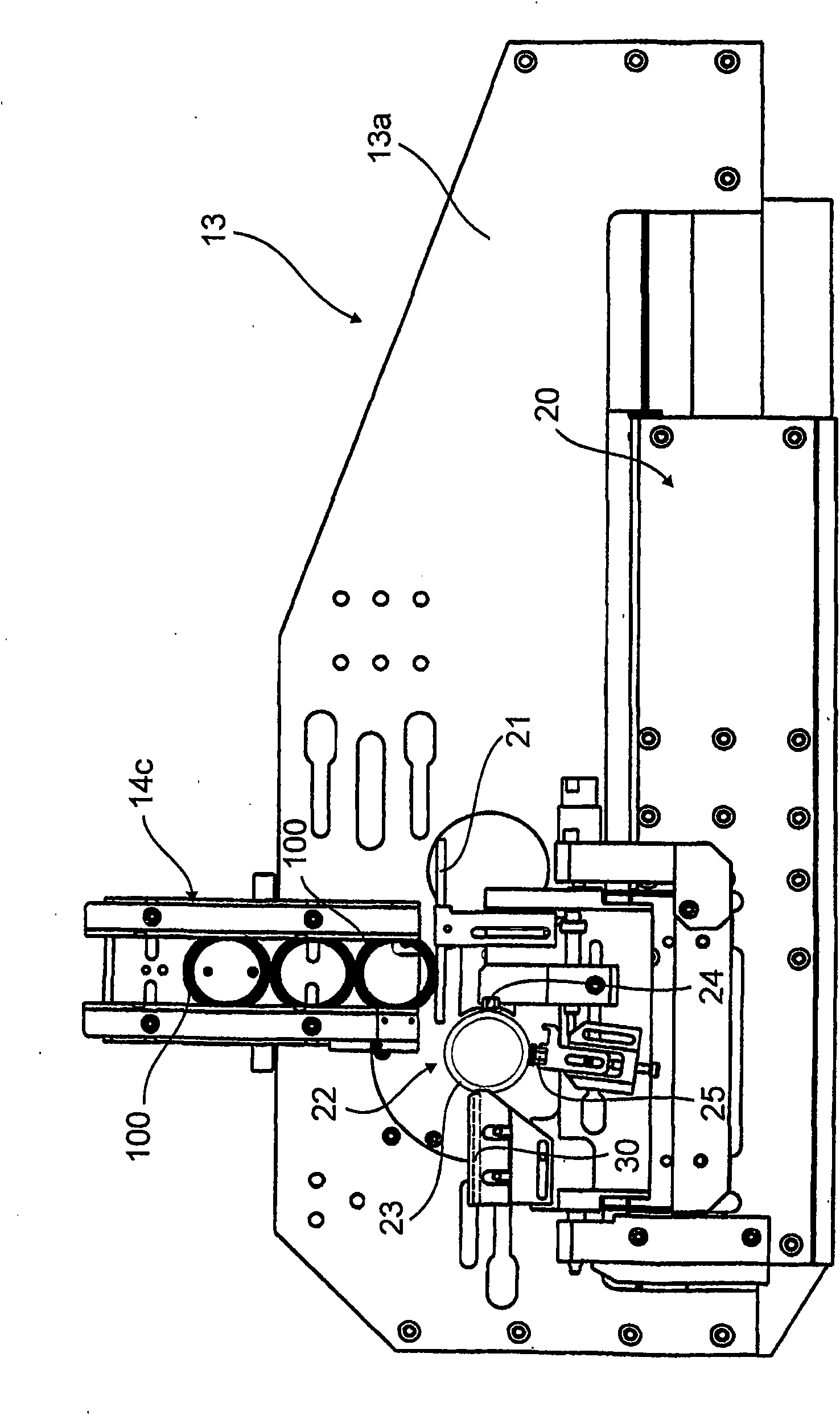

[0031] [31] Reference Figure 1A and 1B , the shown grinding machine 10 includes: a frame 11, which includes a lower part 11a and an upper part 11b; an electrical cabinet 12; , and is connected to an automatic feeding device 14 of the bearing ring to be ground; Figures 3A to 3C An automatic unloading device 15 of the ground ferrule is shown; and a console 16, which is fixed on a movable arm 16a and has a display screen and a keyboard. Preferably, the upper part 11b of the frame 11 is glassed and allows access to the grinding unit 13 . The electrical cabinet 12 includes all electrical components for powering and operating the machine. The space defined by the lower part 11a of the frame contains the hydraulic components and lubricating devices required during the machining of the part. Depending on whether the ring to be ground is the inner ring or the outer ring of the bearing, the grinding unit 13 differs from one machine to another. Since the design of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com