Full automatic grinding machine for piston ring inclined end surface

A piston ring, fully automatic technology, applied in the direction of grinding machine parts, grinding feed movement, grinding/polishing equipment, etc., can solve the problems of low machining accuracy, low machining efficiency, complex machining of piston ring inclined end surface, etc. , to prolong the life of the grinding wheel, improve the machining accuracy, and avoid grinding burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

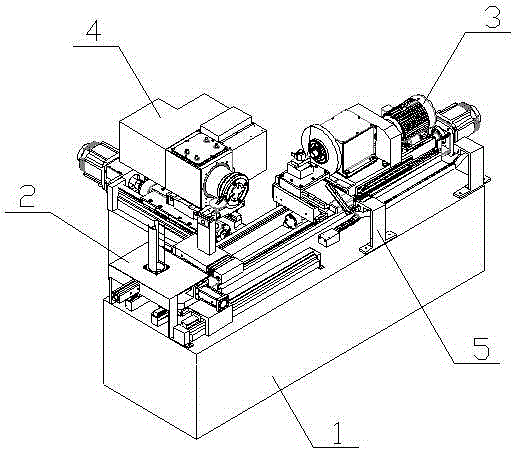

[0027] Example: see figure 1 , a piston ring beveled end fully automatic grinding machine, including a bed 1, automatic loading and unloading frame 2, composite processing table 3, power head frame 4 and collecting frame 5. The bed 1 is provided with two parallel guide rails, the automatic loading and unloading frame 2 and the compound processing table 3 are respectively located at both ends of the two guide rails, and the power head frame 4 and the collecting rack 5 are respectively located on both sides of the two guide rails.

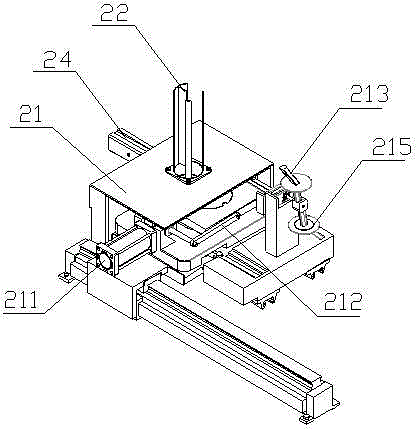

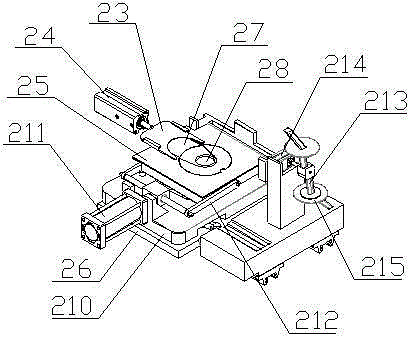

[0028] see Figure 2 to Figure 4 , the automatic loading and unloading rack 2 includes a stocking rack, a feeding slide and a feeding cylinder. The storage rack includes a bracket 21 and a storage pipe 22, and a positioning plate is vertically arranged in the storage pipe 22. When filling the piston ring, the gap of the piston ring is inserted from the upper end of the positioning plate, thereby realizing the piston ring. The positioning makes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com