Automatic double-edge glass edge grinding production line

An automatic production line, glass technology, applied in the direction of grinding feed motion, grinding machine, grinding workpiece support, etc., can solve the problems of continuous glass grinding, need manual assistance, affect the quality of edge grinding, etc., to save labor costs, operation Ease of use and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

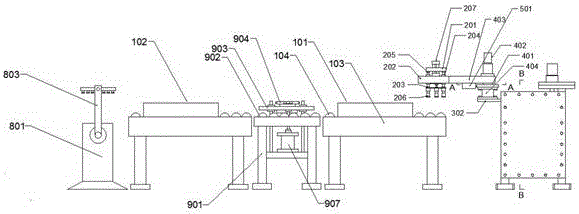

[0029] Including the first edging machine 101, the second edging machine 102 and the steering system arranged between the first edging machine 101 and the second edging machine 102, the feeding system for automatically feeding the glass after edging A blanking system for glass blanking;

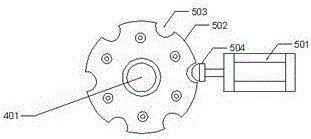

[0030] The first edging machine 101 and the second edging machine 102 have the same structure, and both include a base 103, a conveyor belt 104 mounted on the base 103 to support and transport glass, an edging system for glass on both sides, Positioning system for correcting the position of the glass in front of the edge;

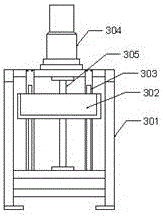

[0031] The feeding system includes a clamping unit for clamping and releasing the glass at an appropriate position, a lifting u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com