Opposite type rail trolley wheel train set and rail changing method thereof

A technology of adjacent tracks and wheel trains, which is applied in the direction of wheels, wheels, and vehicle parts characterized by track running parts, and can solve problems such as car crashes, track cars that cannot walk back and forth in opposite directions, and traffic accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

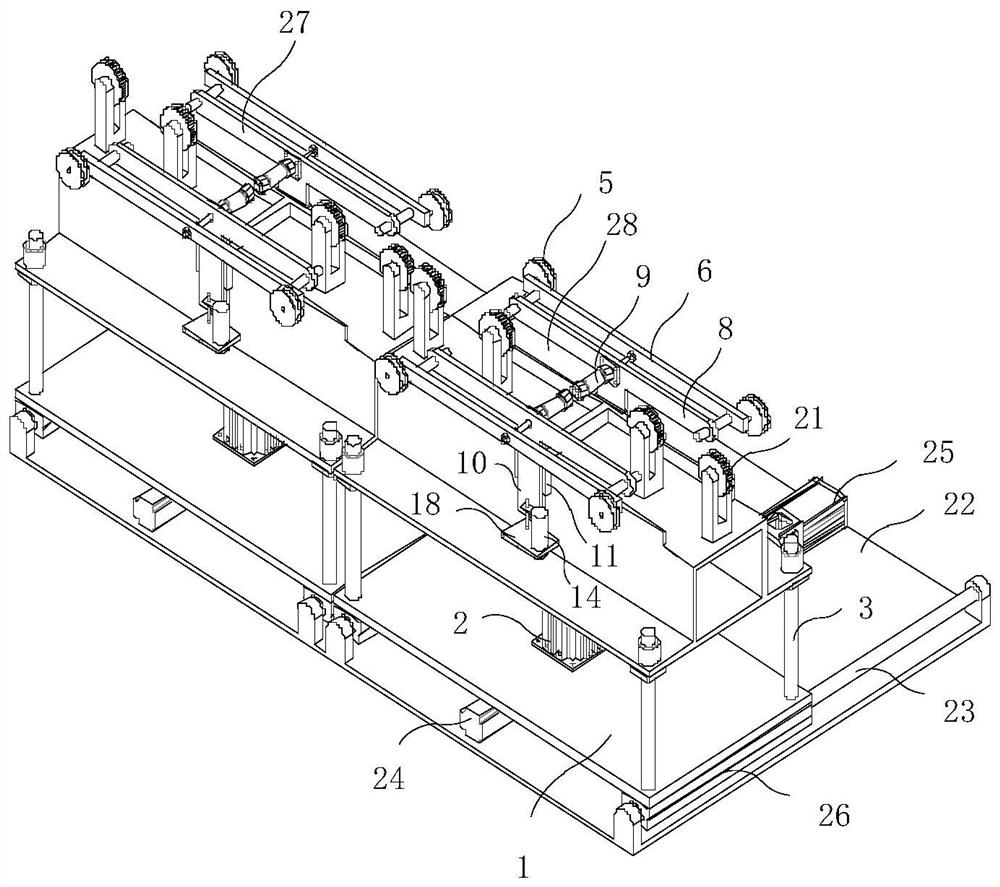

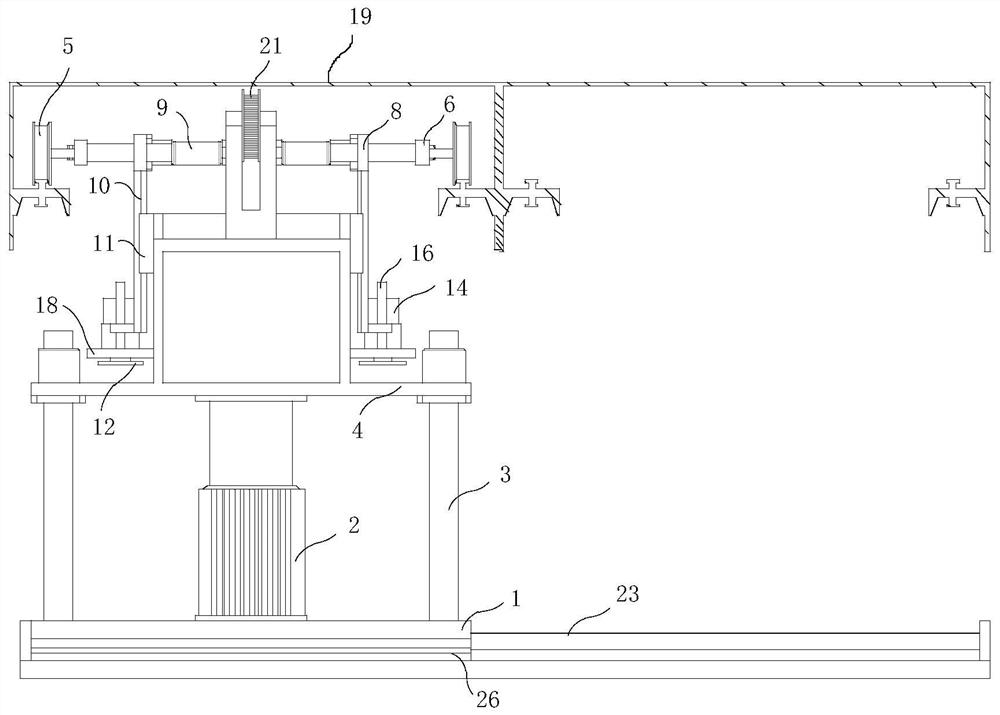

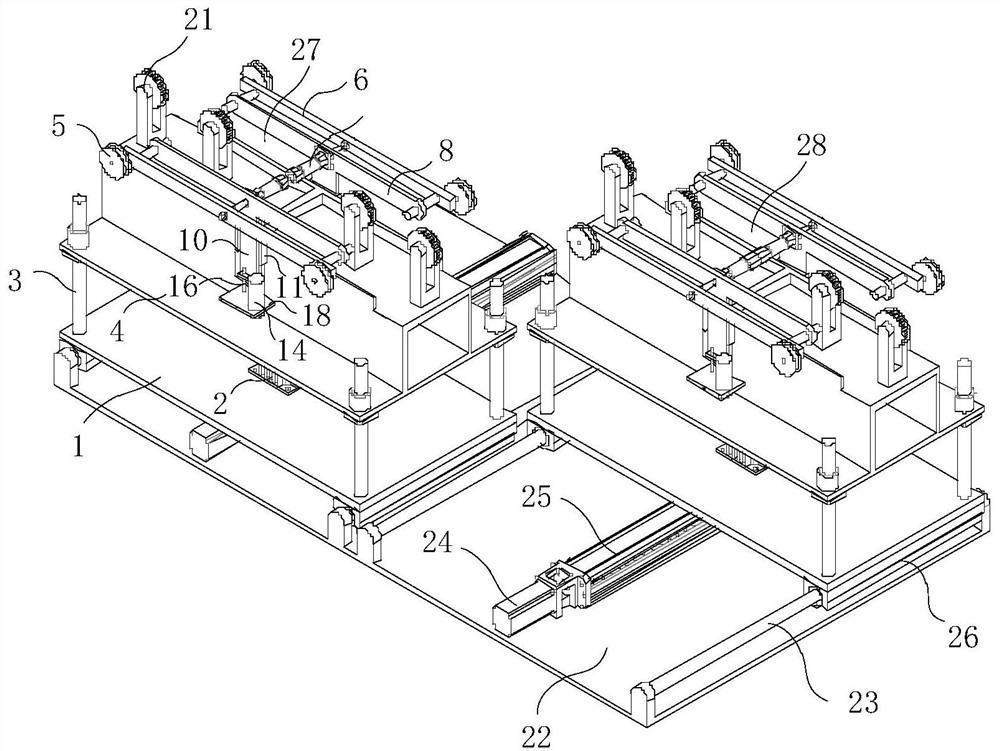

[0056] Such as Figure 1-7 As shown, a kind of opposite type rail trolley wheel train set of the present invention comprises bearing plate 22 and two-character wheel train set. The two-character gear train group includes the A gear train group 27 and the B gear train group 28, and the A gear train group 27 and the B gear train group 28 are respectively installed on the bearing plate 22 one by one through the translation mechanism, that is, the A gear train group 27 corresponds to a translation mechanism, and the B wheel train group 28 also corresponds to a translation mechanism, and the A wheel train group 27 and the B wheel train group 28 can slide along their corresponding translation mechanisms respectively.

[0057]The load plate 22 can be the top plate of the rail car, that is, the A wheel train group 27 and the B wheel train group 28 in this embodiment are all installed on the top of the rail car, and the rail car passes through the A wheel train group 27 and the B wheel...

Embodiment 2

[0069] The present embodiment is a method for changing rails of the opposite-type rail trolley group. Specifically, the present embodiment adopts the opposite-type rail trolley group in Embodiment 1. When in use, the A wheel group 27 and B wheel train group 28 are all suspended on the track, and A wheel train group 27 and B wheel train group 28 are all positioned at one side of load plate 22, as figure 1 shown. The bearing plate 22 is the top plate of the track trolley compartment, that is, the A wheel train group 27 and the B wheel train group 28 are installed on the top of the car. When running normally, the whole track trolley can run forward and backward along the track. When running into other track dollies during driving, you need to change the track and make a wrong car at this time.

[0070] Specifically, such as Figures 14-20 As shown, only the sectional view of the B wheel train group 28 is used to illustrate the specific rail changing process. In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com