Multifunctional stereoscopic desert sand pressing grass growing machine

A multi-functional and three-dimensional technology, applied in the direction of hole seeding machine, seeding, planting method, etc., can solve the problems of high labor intensity, difficulty in mechanically planting grass, and relying on a lot of manpower to plant grass, etc., to increase roughness, reduce wind, prevent The effect of quicksand moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

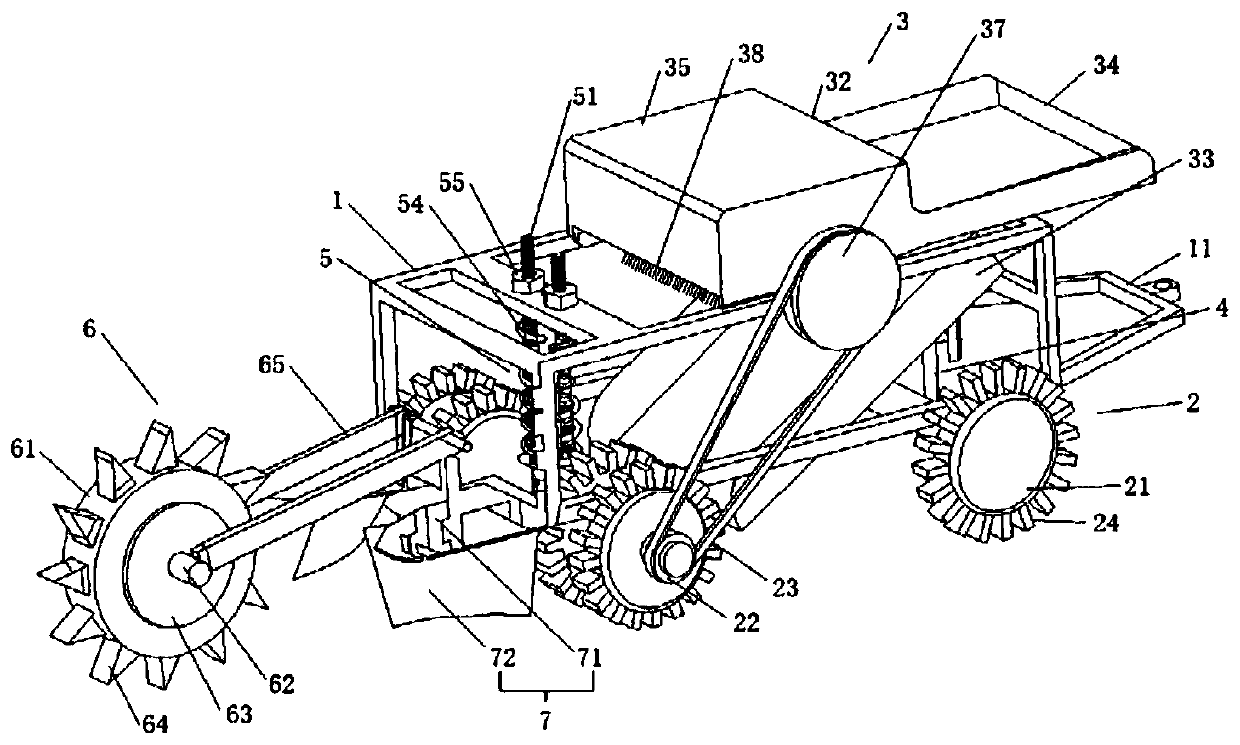

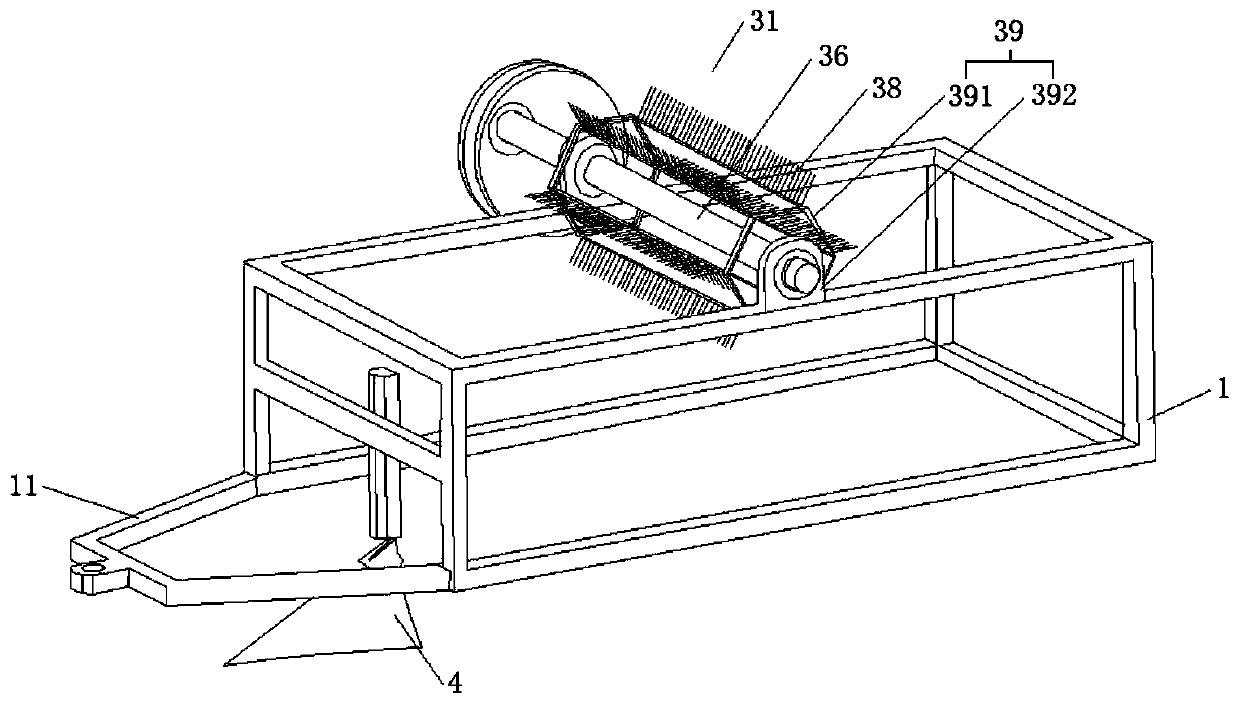

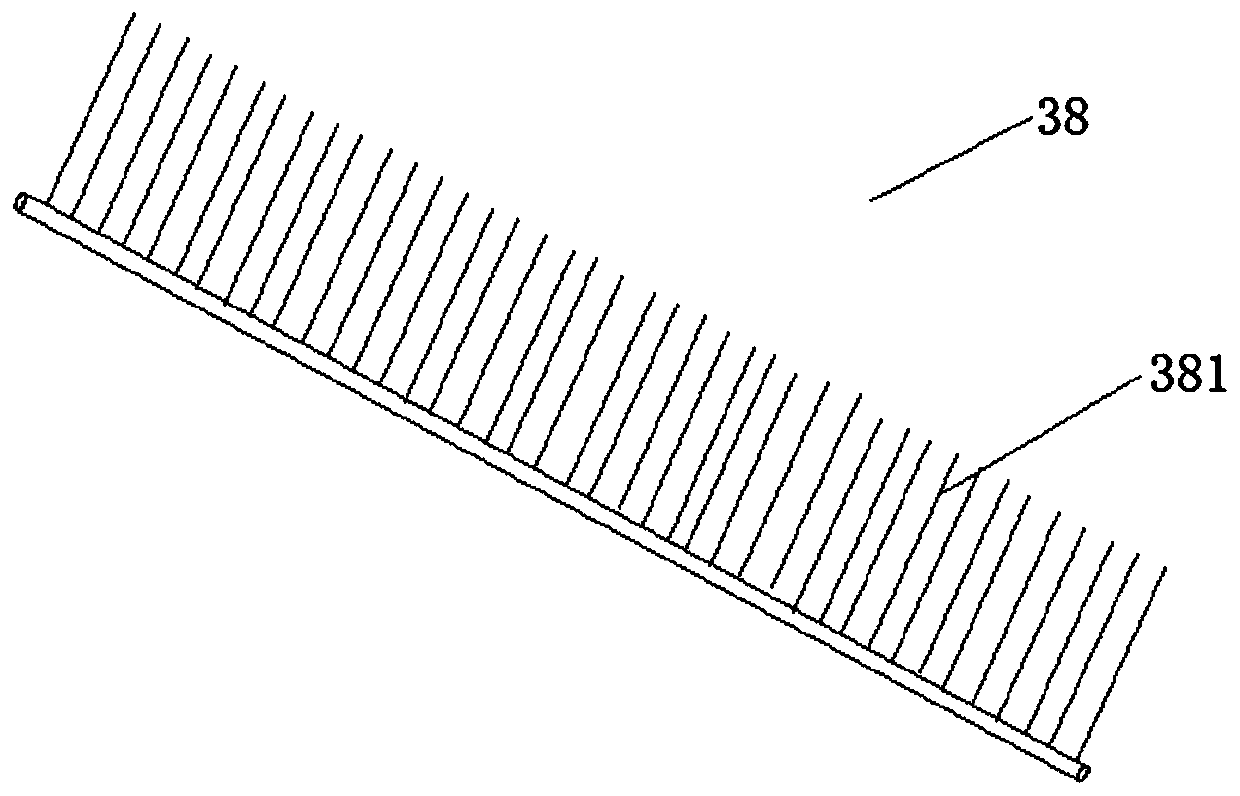

[0033] like figure 1 and 2As shown, the multi-functional three-dimensional desert pressing and grass planting machine includes a frame 1, a walking wheel system 2, a straw laying device 3, a ditching device 4, a straw pressing device 5 and a seeding device 6, and the walking wheel system 2 is installed Below the frame 1, the straw laying device 3 is fixedly installed above the frame 1, and the ditching device 4 is fixedly installed below the frame 1 and is located in front of the straw laying device 3, The straw pressing and soil covering device 5 is fixedly installed under the frame 1 and located behind the straw laying device 3 , and the sowing device 6 is installed on the frame 1 and loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com