High-strength rail trolley wheel train sets and rail replacing method thereof

A high-strength, wheel-train technology, applied to equipment fixed to the track, elevated railway systems using suspended vehicles, motor vehicles, etc., can solve problems such as inability to change rails, narrow coverage, and inability to lengthen the carriage with the track. , to achieve the effect of high-precision walking, broad economic value, and wide coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

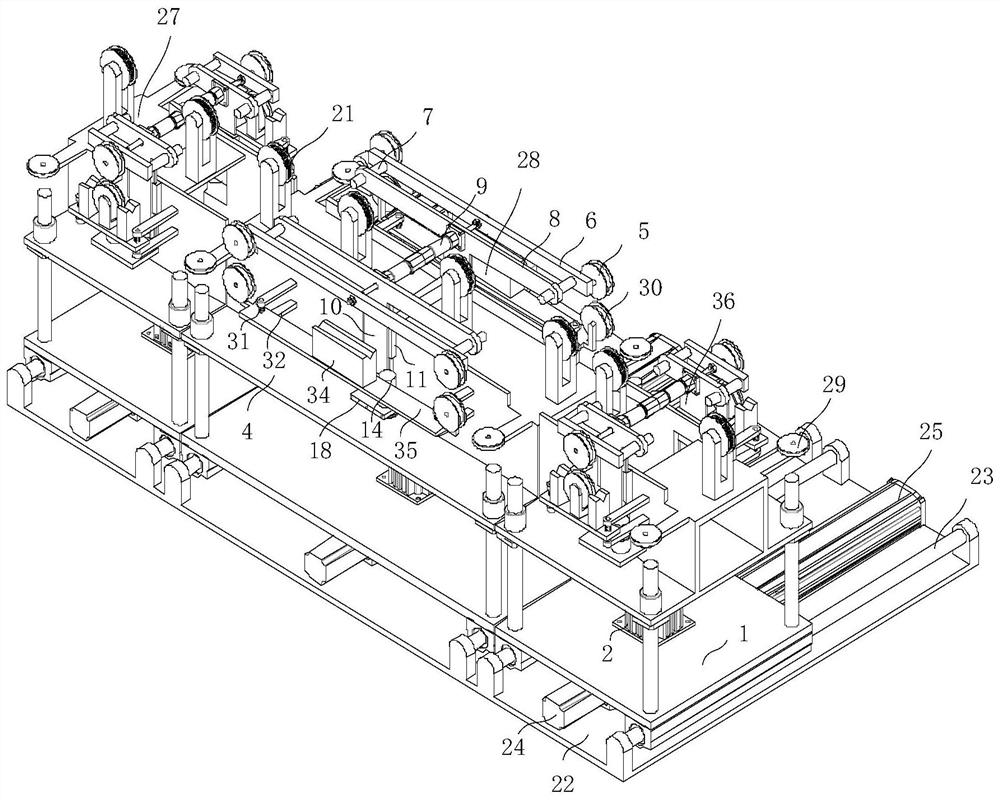

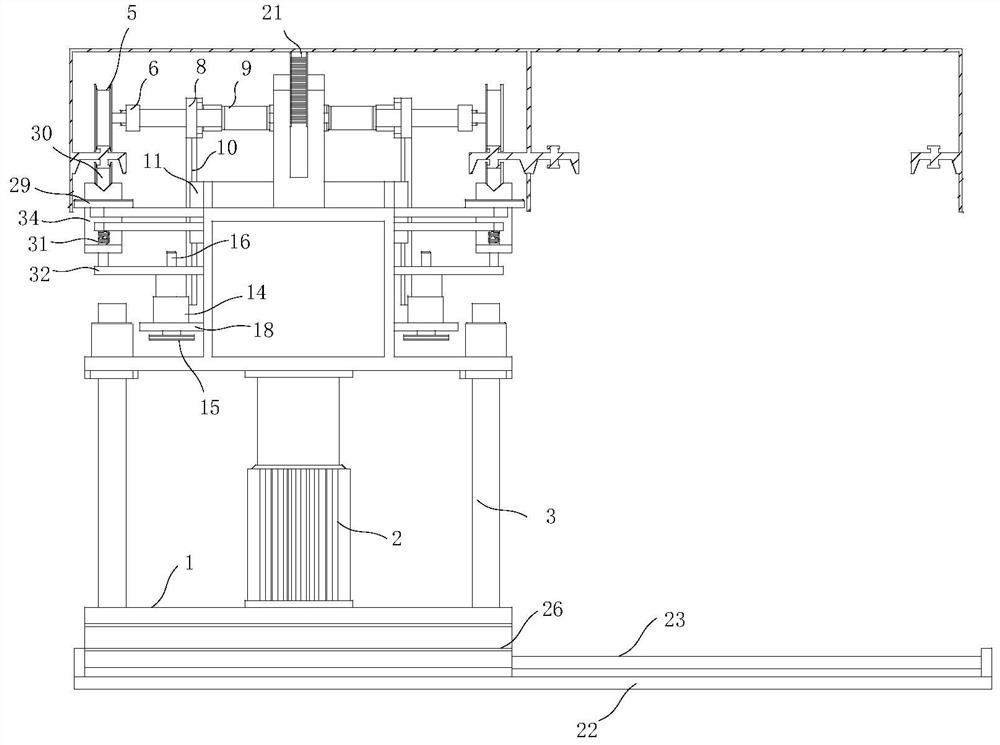

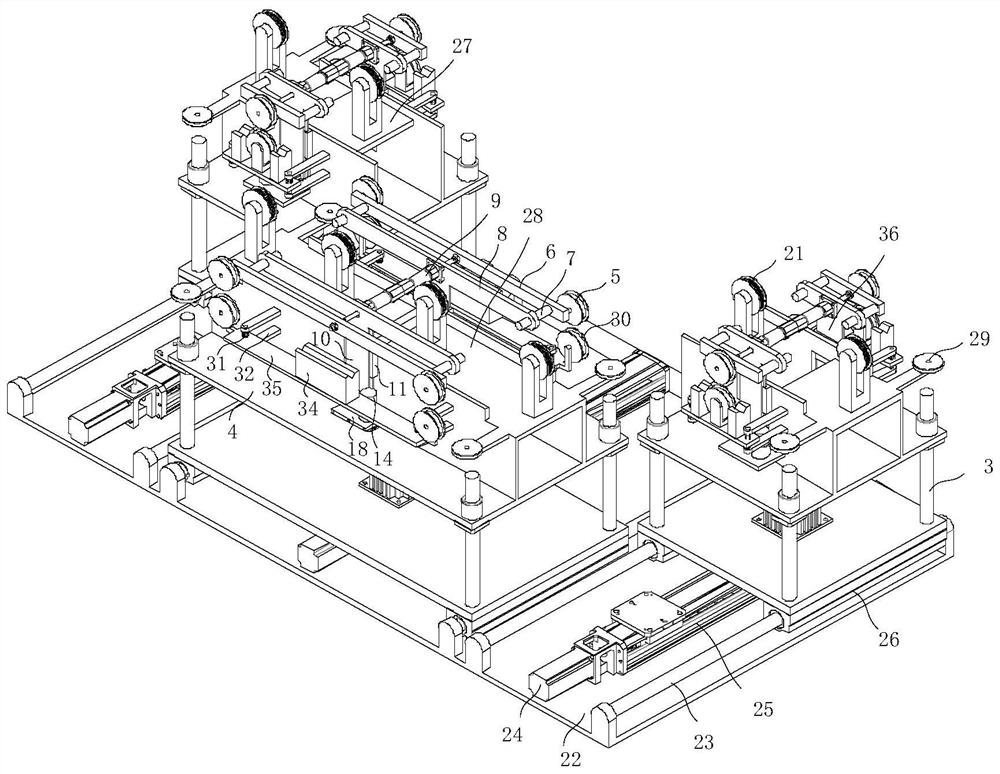

[0060] like Figure 1-7 As shown, a high-strength track trolley train set of the present invention includes a bearing plate 22 and N wheel train sets mounted on the bearing plate 22 through a translation mechanism, wherein N≥3, and in this embodiment, N =3, that is, it is set as a three-character gear train group. Specifically, the three-character gear train group includes the A gear train group 27, the B gear train group 28 and the C gear train group 36, and the A gear train group 27, the B gear train group 28 and the C gear train group 36 are respectively installed on the On the bearing plate 22, that is, the A wheel train group 27 corresponds to a translation mechanism, the B wheel train group 28 corresponds to a translation mechanism, and the C wheel train group also corresponds to a translation mechanism. The A wheel train group 27, the B wheel train group 28 and the C wheel train group The train sets 36 can be arranged along the length direction of the bearing plate 22 ...

Embodiment 2

[0074] This embodiment is basically the same as Embodiment 1, the difference being that the traveling wheel train of this embodiment further includes two magnetic levitation devices respectively arranged on both sides of the wheel train bracket 4 . Described magnetic levitation device comprises two pallet mounts that are arranged on the wheel train bracket 4, the magnet pallet 35 that is installed on the two pallet mounts, is installed on the magnet pallet 35 and with upper supporting wheel 5 A corresponding number of lower rollers 30 , and an electromagnet 34 arranged on the magnet supporting plate 35 . The lower rollers 30 are located below the upper rollers 5 , and their number is the same as that of the upper rollers 5 . The structure and installation method of the lower roller 30 are the same as those of the upper roller 5, and will not be described in detail.

[0075] The supporting plate mounting seat includes two spring mounting plates 32 arranged up and down on the w...

Embodiment 3

[0078] This embodiment is a method for changing rails of a high-strength rail trolley train set in Embodiment 1 or 2.

[0079]Specifically, a high-strength small rail wheel set is provided with N wheel sets, where N≥3, in this embodiment, N=3, that is, three wheel sets are provided, which are A wheel The train group 27, the B train group 28 and the C train group 36. During use, the A wheel train group 27, the B wheel train group 28 and the C wheel train group 36 are all suspended on the track 19, and the A wheel train group 27, the B wheel train group 28 and the C wheel train group 36 are all located on the bearing plate 22 side, such as figure 1 shown. The bearing plate 22 is the top plate of the rail trolley compartment, that is, the A wheel train group 27, the B wheel train group 28 and the C wheel train group 36 are installed on the top of the car. When running normally, the whole track trolley can run forward and backward along the track. When running into other track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com