Series-parallel combined type hybrid power assembly

A hybrid and hybrid technology, applied in hybrid vehicles, power units, air pressure power units, etc., can solve the problems of hybrid powertrains such as limited fuel saving effect, poor emission, and inability to provide air conditioning and power steering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to understand the technical content of the present invention more clearly, the following examples are given in detail. It should be understood that the examples are only used to illustrate the present invention, not to limit the present invention.

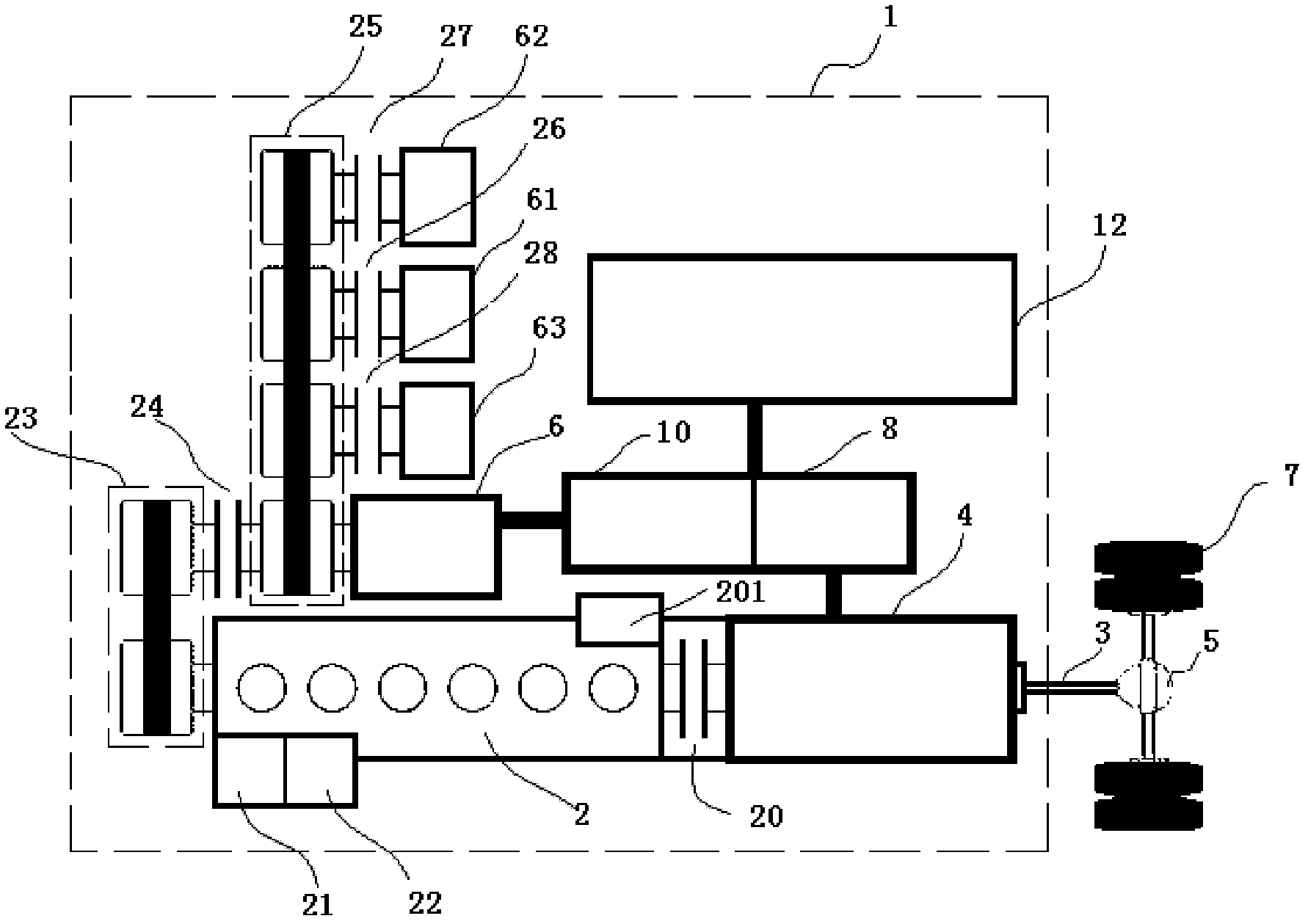

[0035] figure 1 is a system block diagram of the hybrid powertrain according to the embodiment of the present invention. Heavy-duty vehicles (not shown) such as city buses mostly adopt the rear-mounted rear-drive type. The hybrid power assembly 1 is longitudinally arranged behind the driving axle 5, and transmits power to the driving axle 5 and wheels 7 through the transmission shaft 3 to drive the vehicle.

[0036] refer to figure 1 , the hybrid powertrain 1 includes an engine 2 , a first air compressor 21 installed on the engine 2 , and a first power steering oil pump 22 installed at the rear of the first air compressor 21 . The first air compressor 21 is driven by the engine 2; the rotor (not shown) of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com