Machining device and method for resonance auxiliary cracking of connecting rod

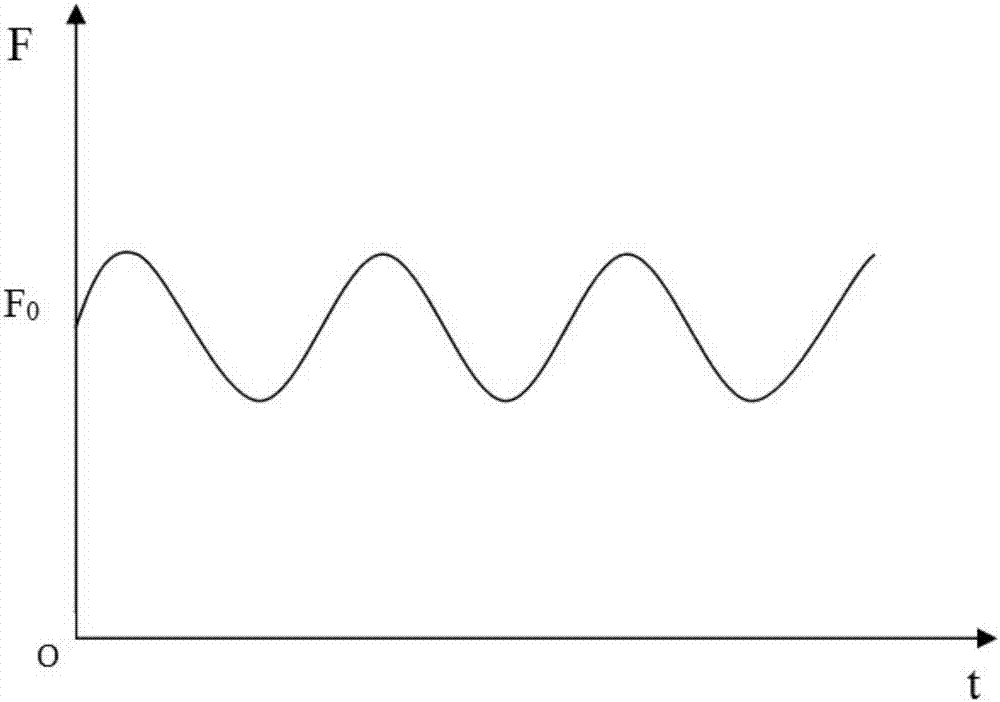

A processing method and connecting rod technology, applied in the direction of connecting rod, metal processing, shaft and bearing, etc., can solve the problem of long time required for fatigue test, inability to solve the problems of slag loss, fatigue fracture of the sample, etc., to achieve the perfect cracking process , The effect of short cracking time and widening range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

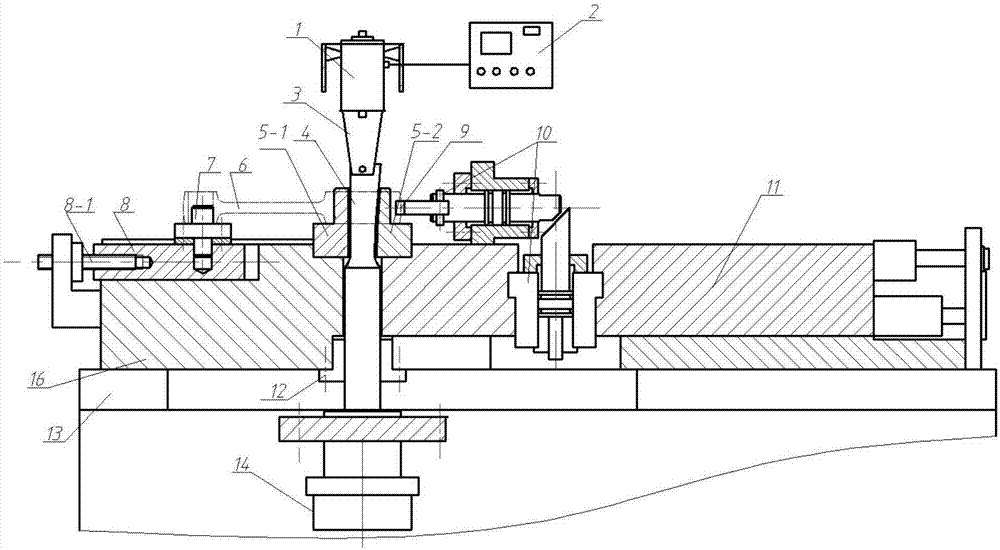

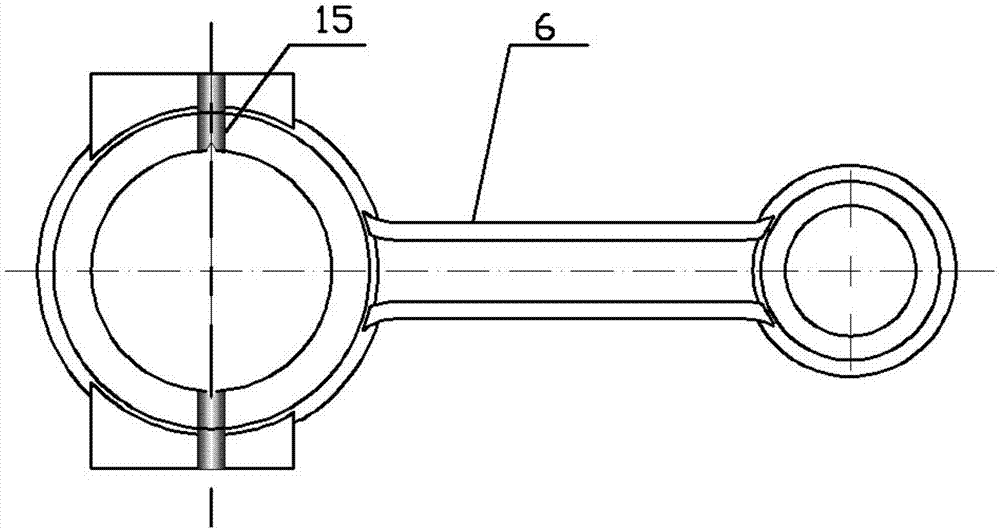

[0037] Such as figure 1 As shown, a processing device for connecting rod resonance assisted cracking, including a vibrator vibration mechanism, a working platform 13, a connecting rod small head hole pressing mechanism, a connecting rod big head hole cracking mechanism and a connecting rod back pressure mechanism 10; The vibrator vibration mechanism includes a vibrator 1 and a connecting rod 3, and the vibrator 1 is installed on the top of the connecting rod 3; the working platform includes a fixed seat 16 and a slide block 11; the slide block 11 can pass through the translation mechanism Translate on the fixed seat 16;

[0038] The cracking mechanism of the big end hole of the connecting rod comprises a wedge-shaped pull rod 4, a cracking fixed sleeve 5-1, a cracking mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com