Manufacturing method for steel cracking connecting rod

A manufacturing method and technology for cracking connecting rods, which are applied in the direction of connecting rods, manufacturing tools, casting and molding equipment, etc., can solve problems such as crack bifurcation, cracking, and cross-sectional deformation, so as to improve tearing, reduce cracking force, The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

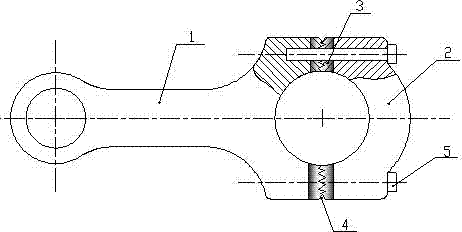

[0031] Example 1 The connecting rod blank is manufactured by the lost foam casting process. The main material of the connecting rod is medium carbon steel 40Cr, which is moderately priced and easy to process. After heat treatment, it can manufacture connecting rod parts that withstand high loads and impacts. Due to its high toughness, brittle cracking cannot be achieved at room temperature and cannot be used for cracking Manufacturing of connecting rods. Gray cast iron chooses HT200, its plasticity and toughness are far lower than steel, and it is easy to be brittle and split. Its melting point is 1145~1250°C.

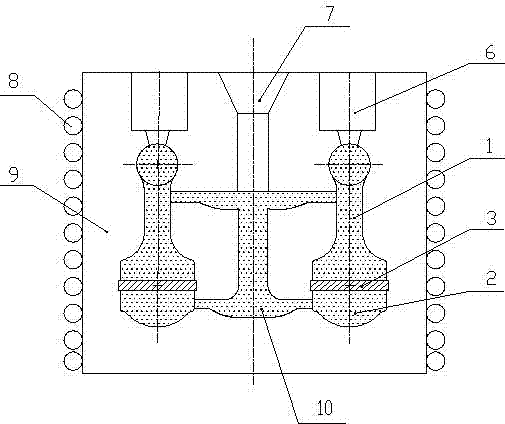

[0032] Figure 2 is the process diagram of the lost foam casting of connecting rods. The connecting rods are arranged vertically, with the big end of the connecting rod facing downward and the small end facing upward. And sprue 7 adopts the direct molding of wooden formwork. During mold manufacture, at first make the mold of the polystyrene foam mold of connecting rod...

Embodiment 2

[0036] Example 2 An investment casting process is used to manufacture a steel connecting rod blank. The main material of the connecting rod is medium carbon steel 40Cr, which is moderately priced and easy to process. After heat treatment, it can manufacture connecting rod parts that withstand high loads and impacts. Due to its high toughness, brittle cracking cannot be achieved at room temperature and cannot be used for cracking Manufacturing of connecting rods. Gray cast iron chooses HT200, its plasticity and toughness are far lower than steel, and it is easy to be brittle and split. Its melting point is 1145~1250°C.

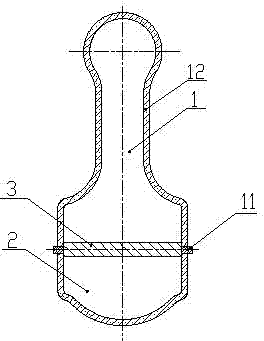

[0037] Using the investment casting process, firstly, according to the shape of the connecting rod to be manufactured, a wax mold of the connecting rod is made, and a rectangular cavity is opened on the connecting rod body 1 and the connecting rod cover 2 on the connecting rod wax model. To install the gray cast iron sheet 3, and bond the sprue rod and the inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com