Transmission device

A transmission device and transmission shaft technology, which is applied to wheel transmission devices, rotary transmission devices, transmission parts, etc., can solve the problems of reduced meshing accuracy, trembling, and reduced service life of gear pairs, so as to reduce gear meshing noise and avoid Shivering and numbness, the effect of eliminating abnormal wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

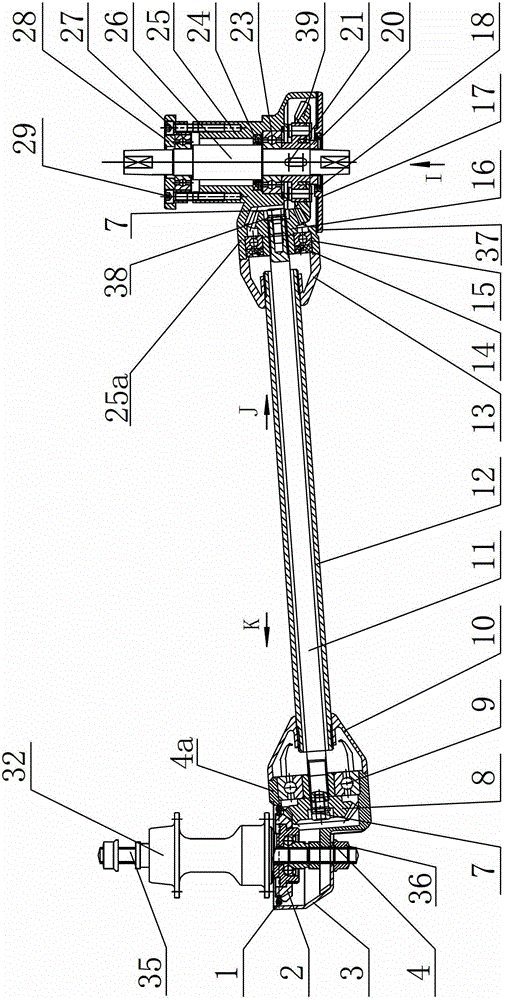

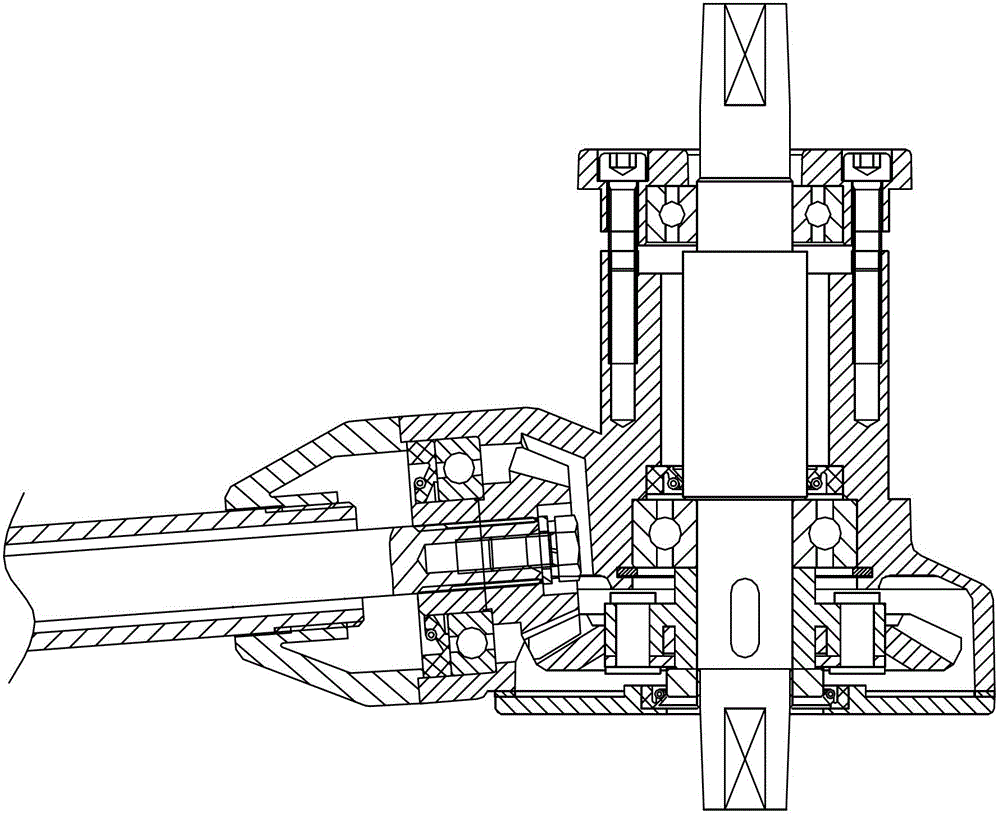

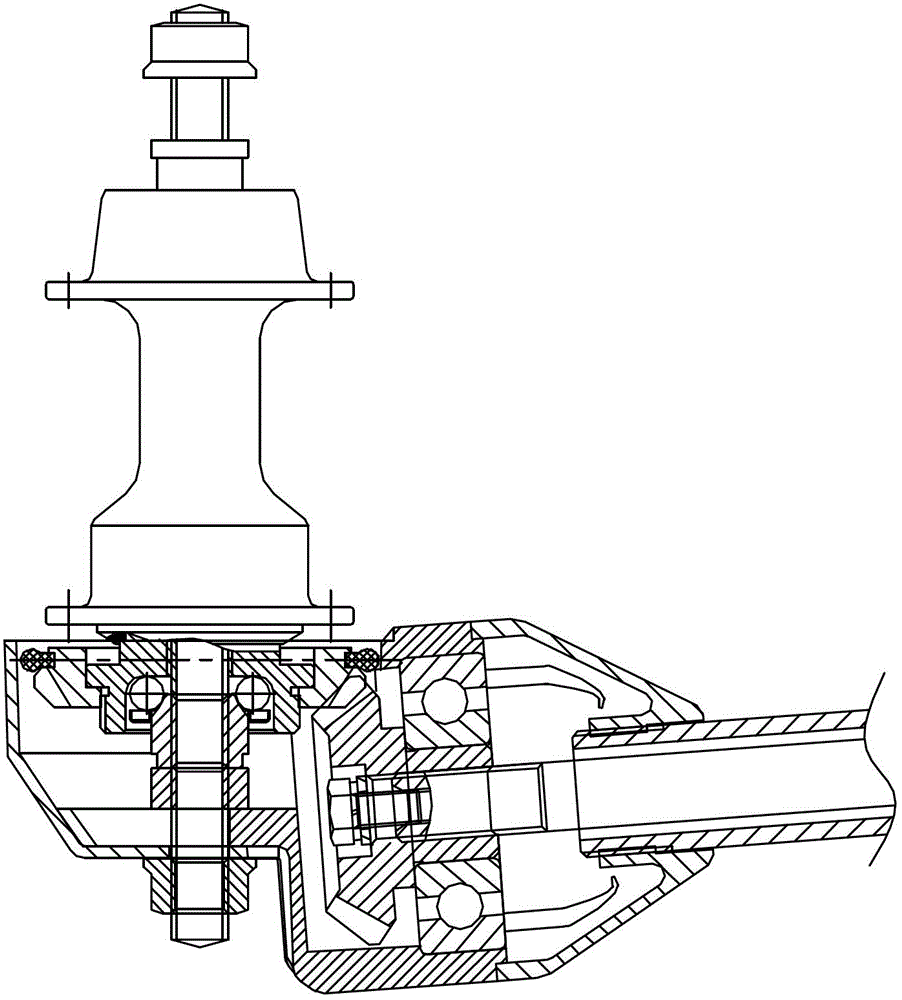

[0032] a kind of like Figure 1-4The transmission device shown is specifically an oil-bath shaft transmission device with a buffer function for replacing a traditional bicycle chain transmission system, which includes an input gearbox 25 provided with a bicycle pedal center shaft 26, and a hub 32 provided with a rear wheel hub of a bicycle. Output gear box 4, the first driving bevel gear 39 and the first driven bevel gear 16 which mesh with each other are arranged in the input gear box 25, and the first driven bevel gear 16 and the wheel in the output gear box 4 The two systems are connected by power transmission through the transmission shaft 11, and the first driving bevel gear 39 and the central shaft 26 are fixedly connected by a bushing 41, and the bushing 41 is fixed on the central shaft 26 through a spline limit, The first driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com