Special assembling machine for large screw-type rotor

A screw type and rotor technology, which is applied in the field of assembly of large screw type rotors, can solve problems such as inconvenient operation, potential safety hazards, damaged bearing bushes, etc., and achieves good stability, no collision, and reduced assembly damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

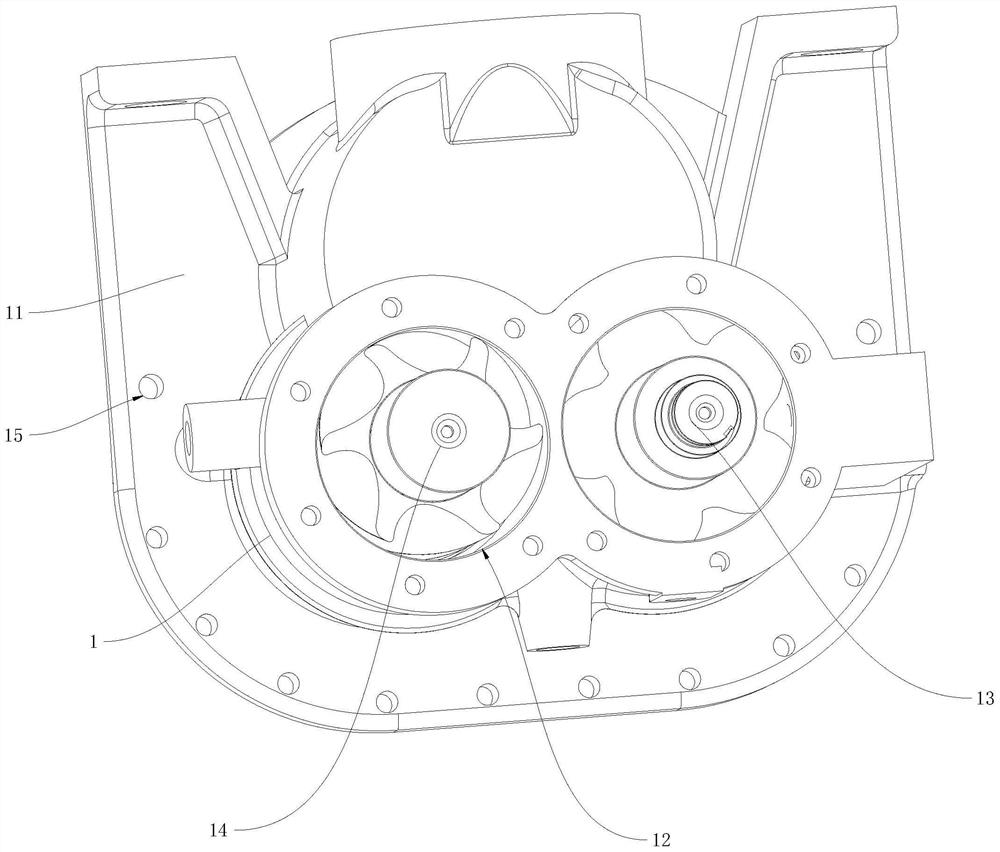

Embodiment 1

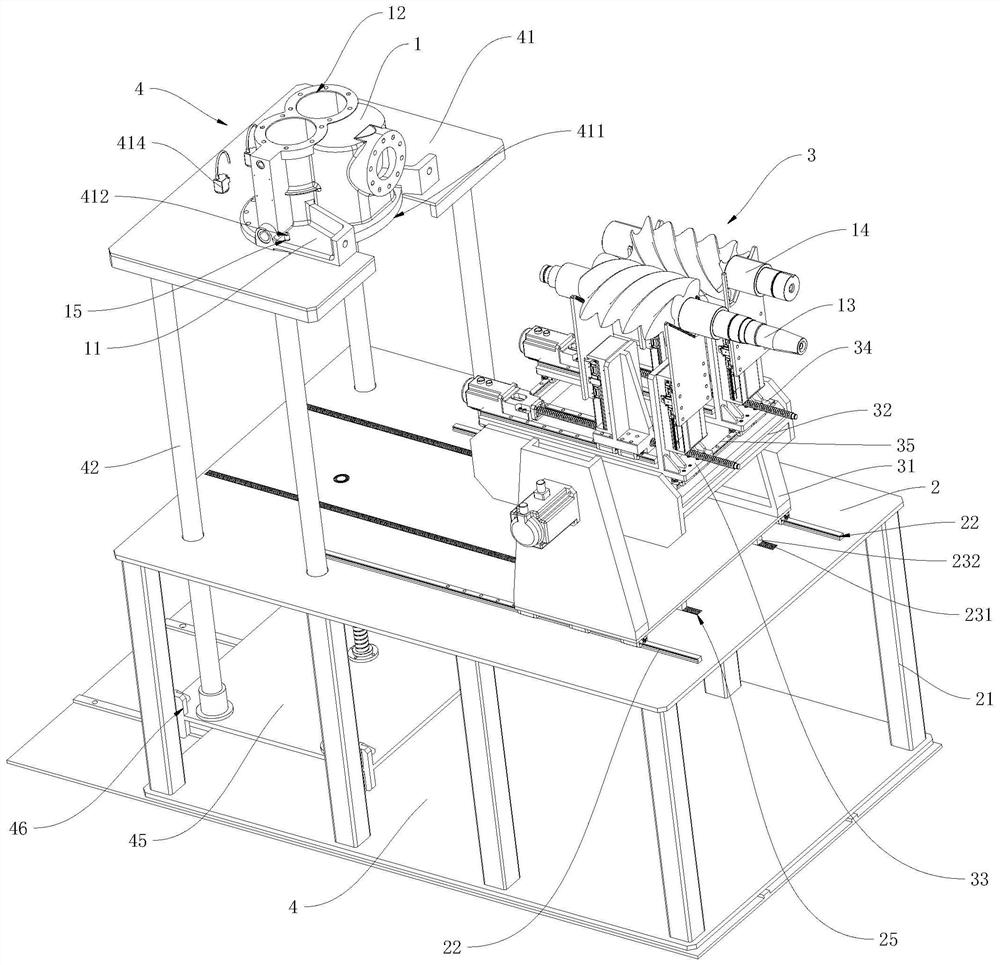

[0047] refer to figure 2 and image 3 , which is a special assembly machine for a large-scale screw rotor disclosed in the present invention, includes a cuboid-shaped bearing plate 2, four legs 21 are fixedly connected to the lower side of the bearing plate 2, and the four legs 21 are respectively located on the bearing plate 2 at the four sharp corners; the upper side of the bearing plate 21 is provided with a two-rotor automatic meshing device 3, an exhaust end seat bearing device 4, and a special machine data processing center, and the two rotor automatic meshing devices 3 can tend to approach along the length direction of the carrier plate 2 The exhaust end seat carrying device moves in 4 directions.

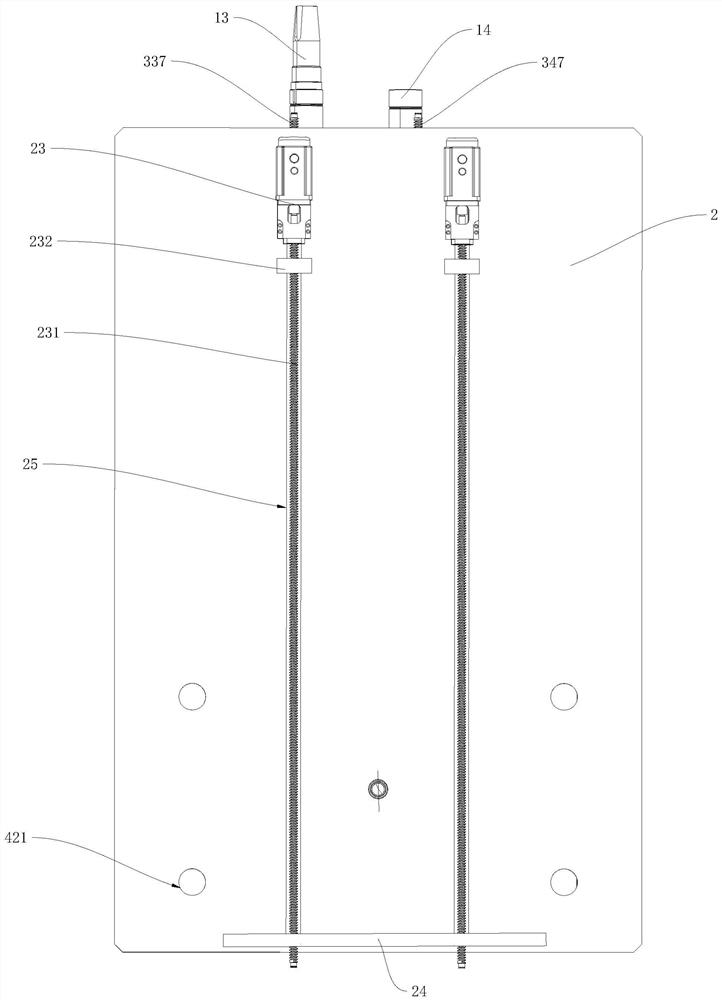

[0048] The supporting plate 2 is provided with a first guiding mechanism 22 for guiding the two rotor automatic meshing devices 3 towards the direction of the exhaust end seat supporting device 4. The number of the first guiding mechanisms 22 is two groups and the first tw...

Embodiment 2

[0066] The difference between this embodiment and Embodiment 1 is that in this embodiment, refer to Figure 10 to Figure 13 , the lifting plate 41 is vertically arranged, and the side of the lifting plate 41 close to the automatic meshing device 3 of the two rotors is provided with a through groove 411, the axis of the through groove 411 is arranged horizontally and the through groove 411 runs through the lifting plate 41 along its axis direction, so as to be able to carry The exhaust end seat 1 and the male rotor 13 and the female rotor 14 are respectively inserted into the slots 12 corresponding to the exhaust end seat 1 through the through groove 411; the through groove 411 extends upward to the upper end of the lifting plate 41 to form an opening, It is convenient for the exhaust end seat 1 to be placed in the through groove 411 . There is also a horizontal supporting plate 416 fixedly connected to the bottom of the middle part of the lifting plate 41 corresponding to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com