Pushing gear and rack

A technology of gears and racks, which is applied in the direction of belts/chains/gears, components with teeth, hoisting devices, etc., can solve the problems of low meshing precision of casting teeth, low working efficiency of electric shovels, long replacement period, etc., to achieve The effect of improving strength and service life, improving performance strength, and prolonging the life of consumable parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

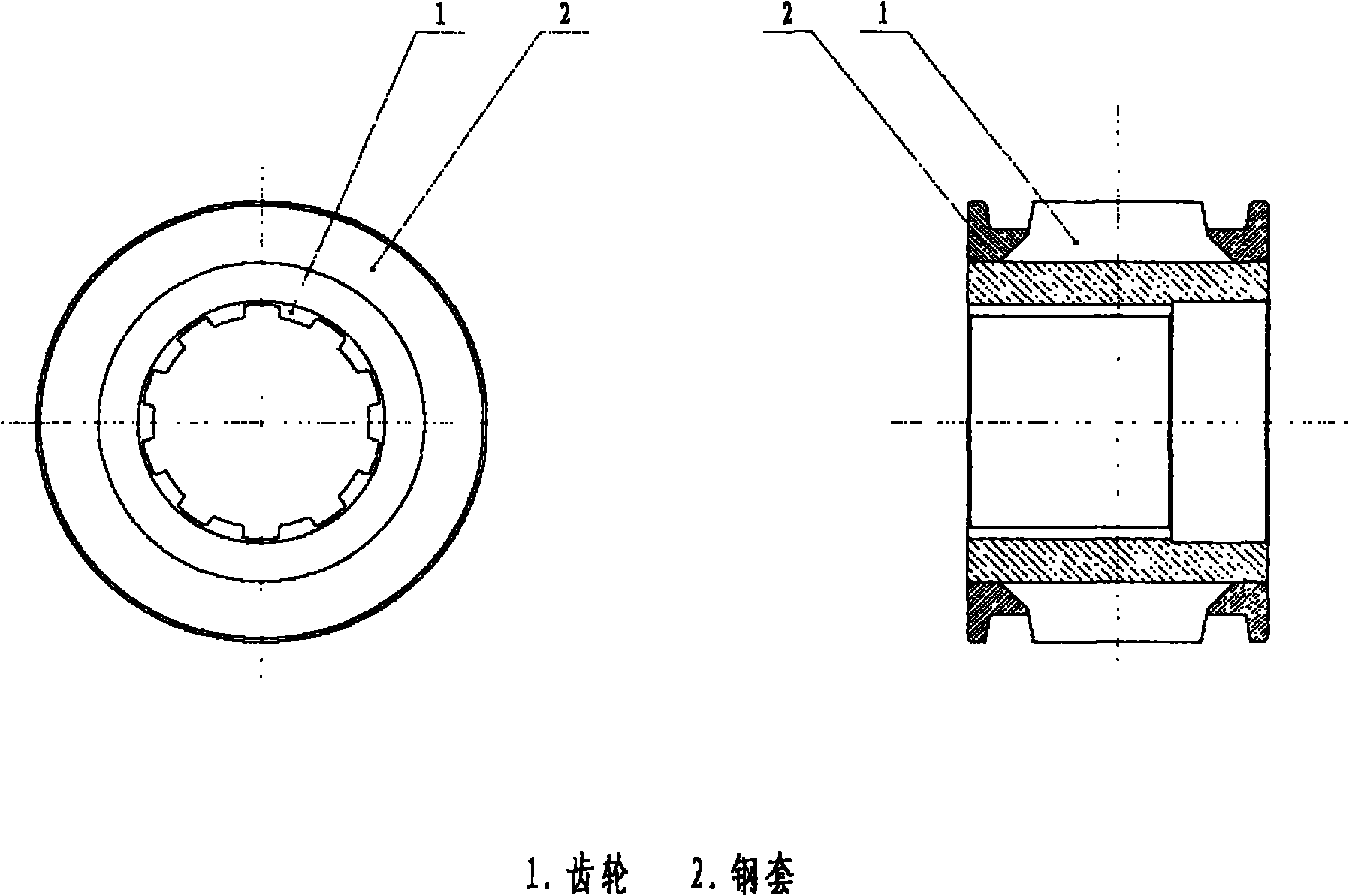

[0013] 1. Implementation of the pair of gears

[0014] The part of the gear (1) and the steel sleeves (2) at both ends of the gear are designed separately, the casting molding is changed into a forging blank, and the gear blank and the steel sleeve blank are respectively forged. Rough machining of gear blanks → quenching and tempering → turning → milling teeth → processing splines. Quenching and tempering of the steel sleeve blank → turning, after processing the gear is installed and welded → trimming the shape and surface quenching to meet the requirements of the drawing.

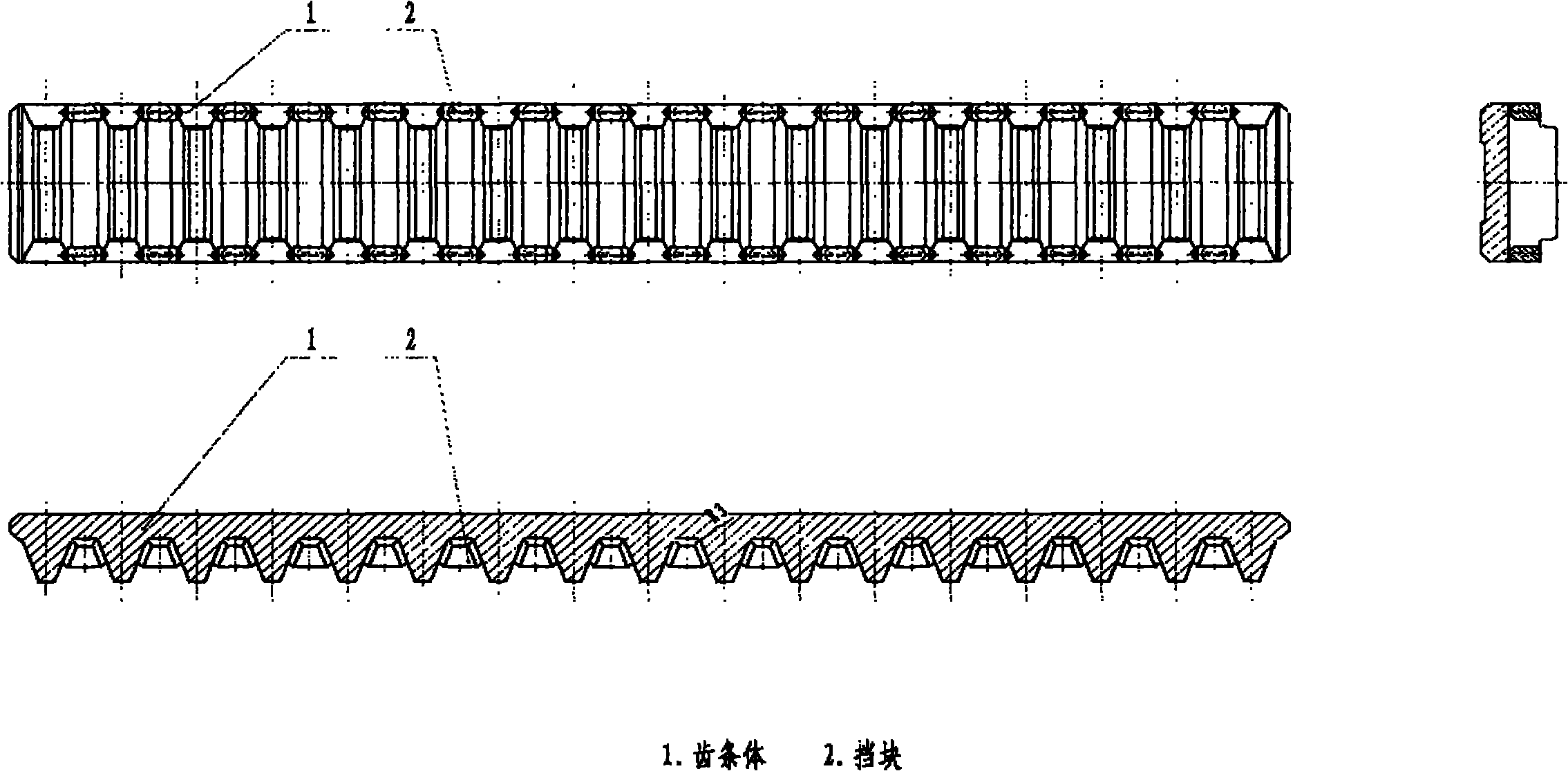

[0015] 2. Implementation of the rack

[0016] The rack formed by integral casting is divided into two parts: a rack body (1) and a stopper (2). The rack body is forged with 35CrMo. After quenching and tempering, continue to process to the drawing requirements. The stop block is cut and processed from the steel plate of the same material, welded and shaped with the rack body, and after straightening, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com