Automatic flatbed printing machine

A printing machine and flatbed technology, applied in the field of automatic flatbed printing machines, can solve the problems of difficult to achieve satisfactory results, uneven pressure, low positioning accuracy, etc., and achieve the effects of great practical and popularization value, reasonable structure, and high printing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

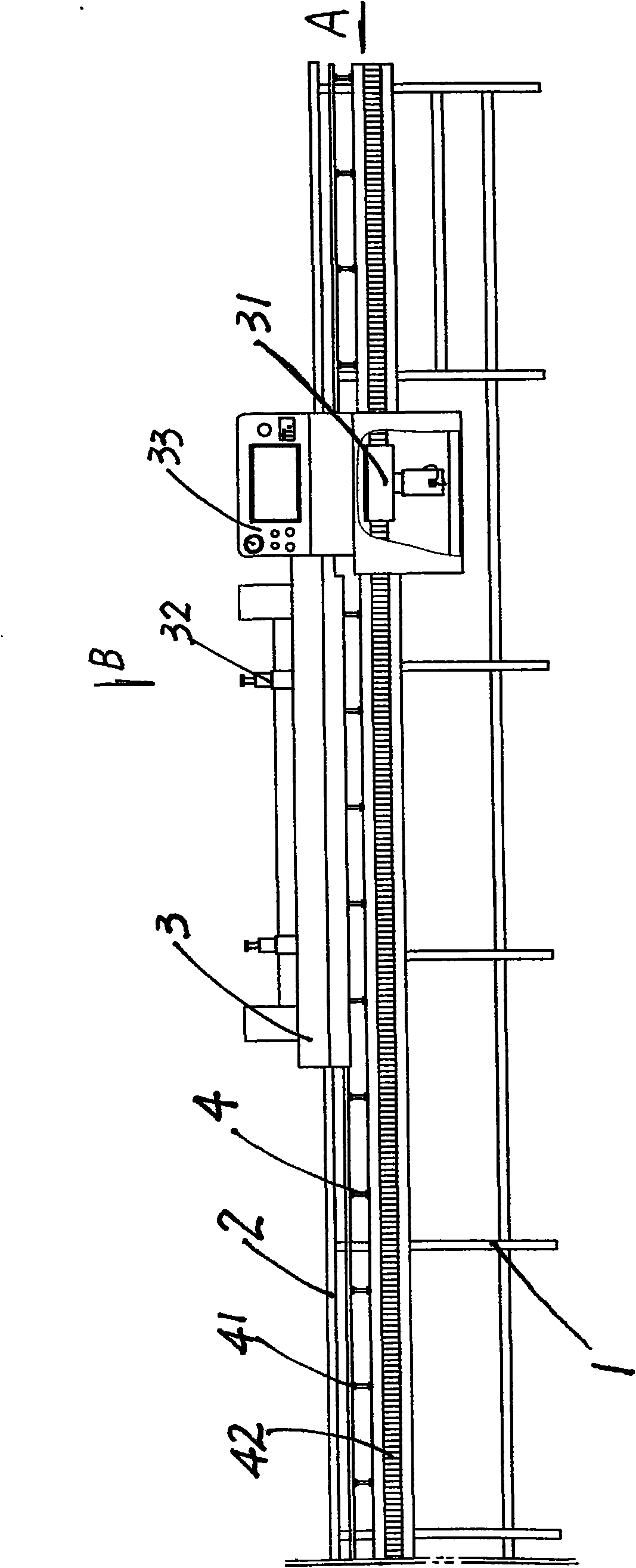

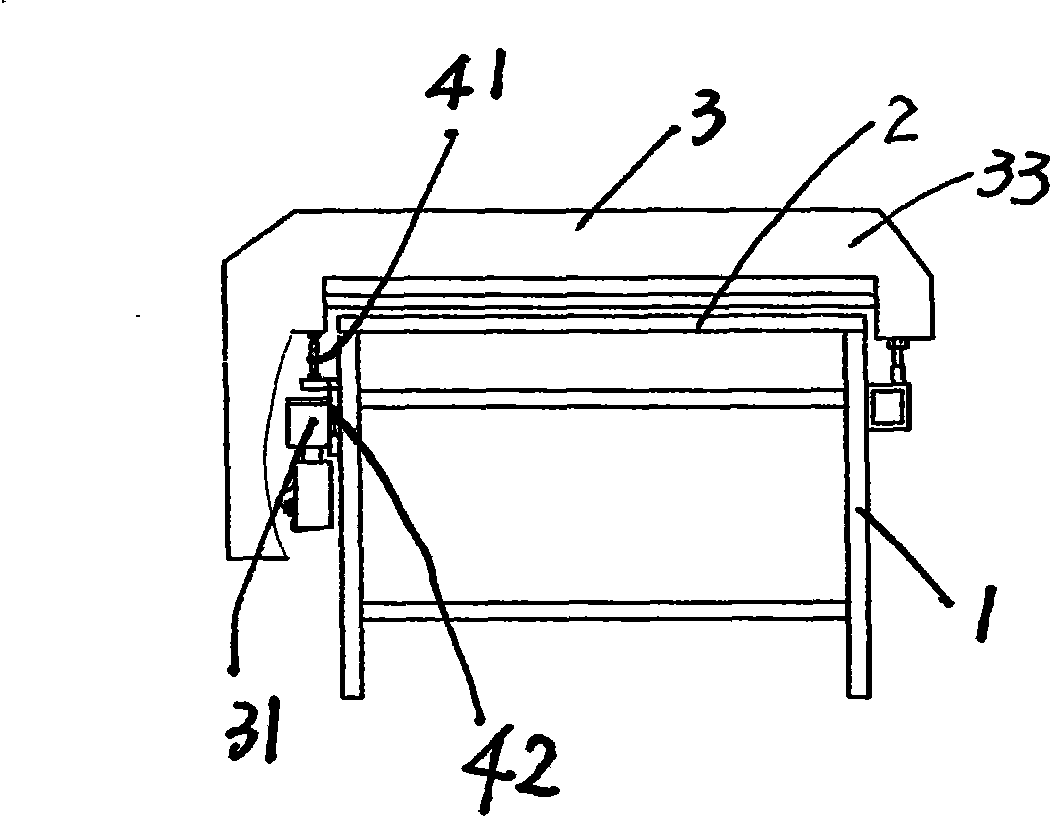

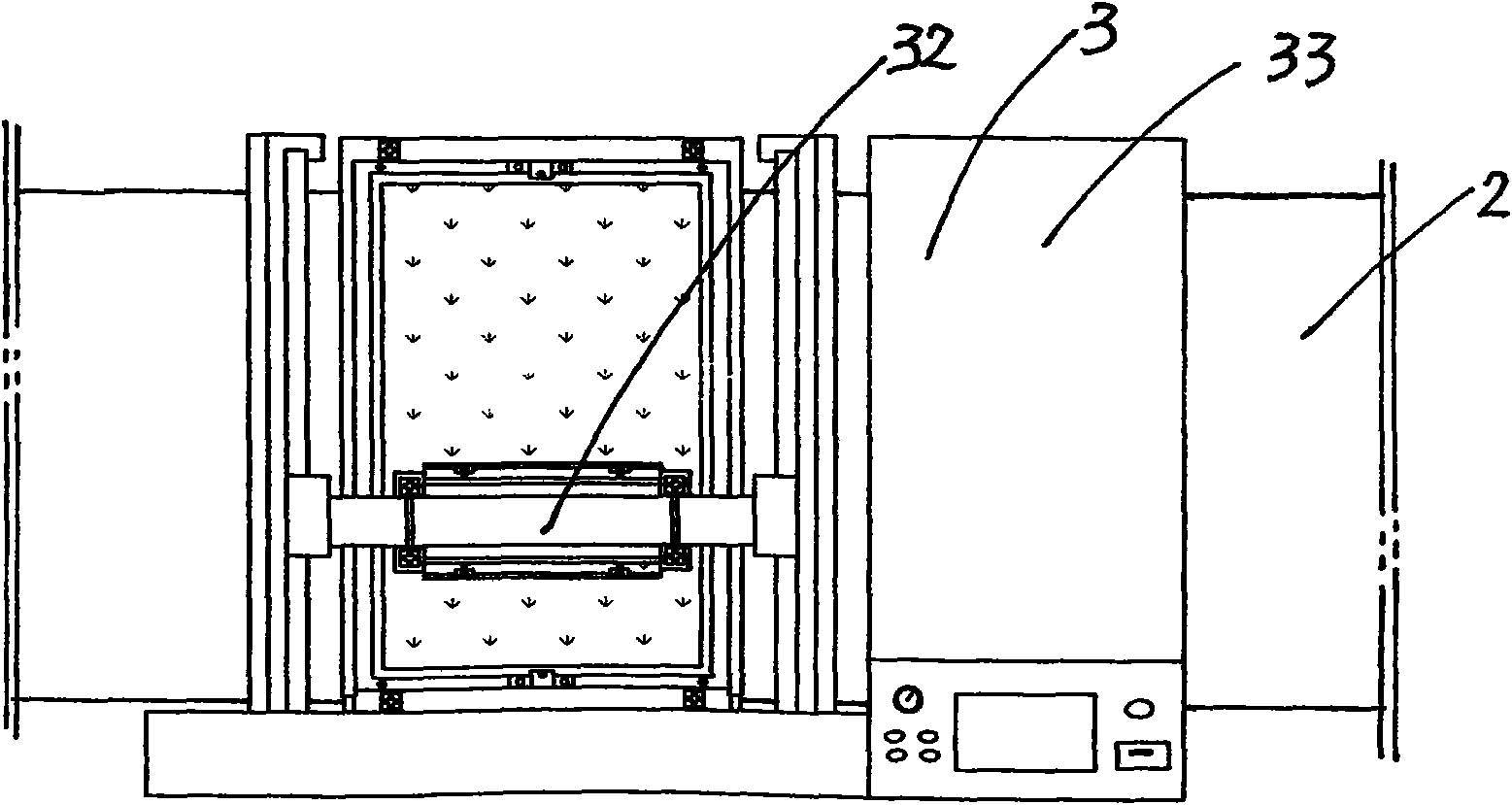

[0019] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , the automatic flat printing machine of the present invention is made up of frame 1, work table 2, mobile work table 3, guide rail part 4, work table 2 is connected with frame 1; Guide rail part 4 is arranged on the frame 1; 3 can move left and right along the guide rail of the guide rail component 4. The mobile worktable 3 is a computer-controlled mobile printing device. The mobile workbench 3 is composed of a walker 31, a scraping part 32, and a console 33. The work of the walking device 31 and the scraping part 32 is controlled by the console 33; the walking device 31 is a servo motor or a stepping motor driven by a synchronous belt to form a crawler-type walking device; the scraping part 32 is a The printing device of automatic control; Described console 33 is the control device that computer controls scraping printing speed, walking step and step distance; The device 315 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com