Back-clearance-free transmission method for large high-precision rotating disc

A high-precision, turntable technology, used in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of complex structure, high cost, and difficult processing, and achieve large and simple structure of the turntable. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

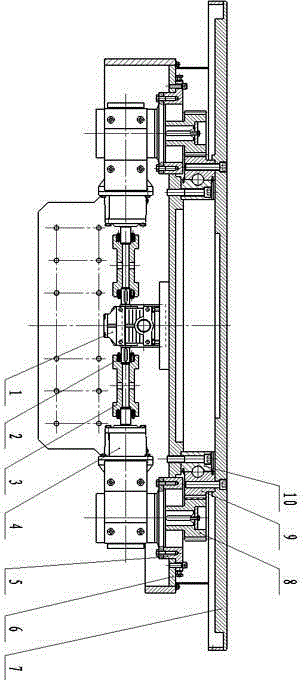

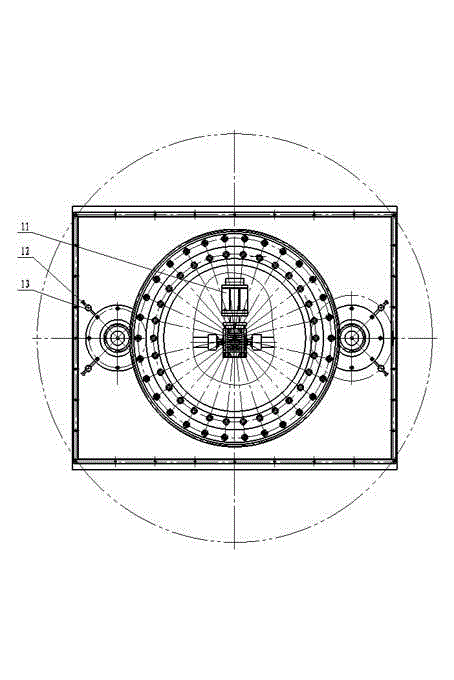

[0015] exist figure 1 and figure 2 Among them, the servo motor (11) is connected to the input end of the primary reducer (1) through a flange, and the primary reducer (1) has dual output shaft output, and the output rotation direction is the same, and the output shaft is 90° to the input shaft. Angle, the output shaft of the primary reducer (1) is connected with the connecting shaft (3) through the expansion sleeve (2), the connecting shaft (3) and the secondary reducer (4) are also connected through the expansion sleeve, and the secondary reducer (4) The input shaft and the output shaft form an angle of 90o. The input direction of the two two-stage reducers is opposite and the output direction is the same. The output flange and the flange (5) are connected by bolts, and the flange (5) is turned over The disc (6) is connected by bolts, the output shaft of the secondary reducer (4) is connected with the pinion (8) through a key, and the pinion (8) meshes with the gear of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com