Gapless gear transmission multifunctional limiter

A gear transmission, multi-functional technology, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve problems such as potential safety hazards, and achieve the effects of low cost, reduced risk, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

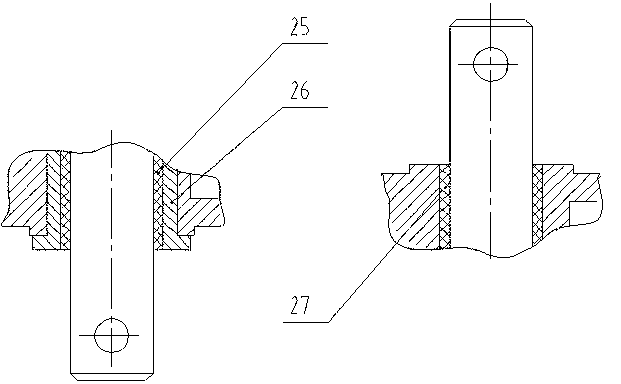

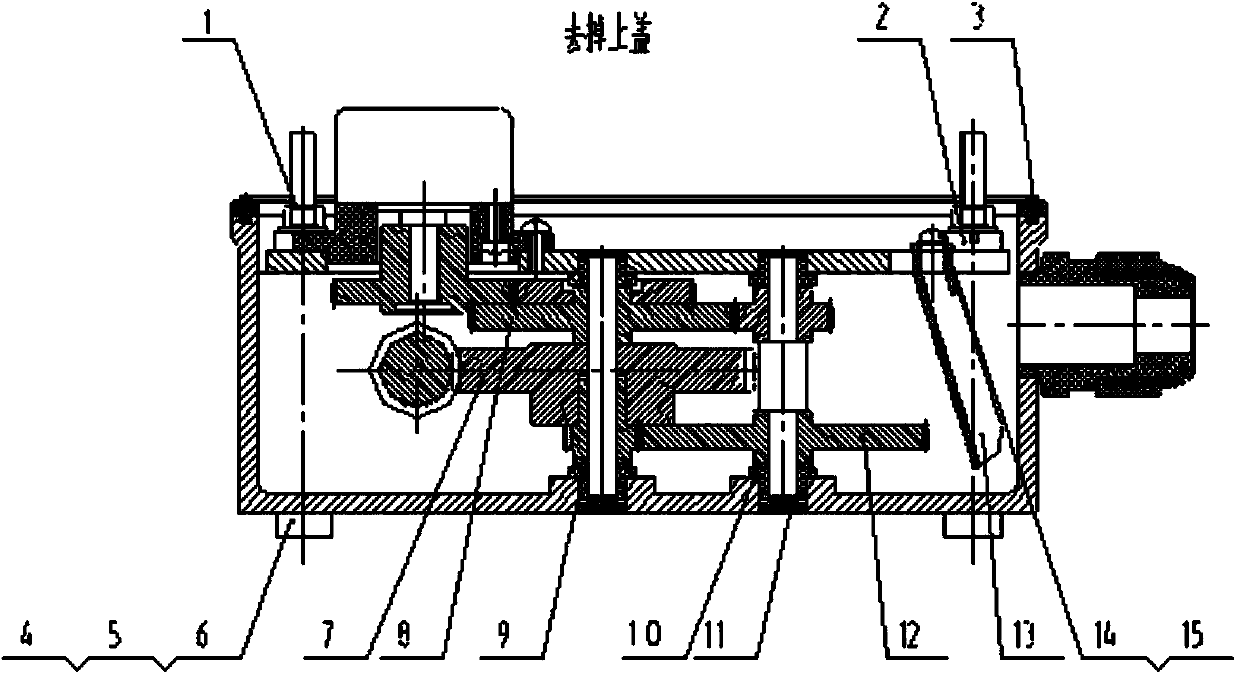

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

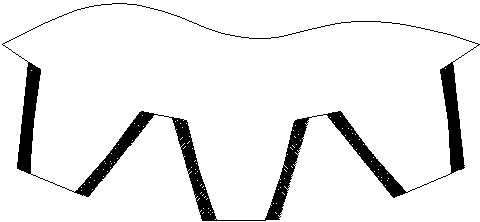

[0029] refer to Figures 1 to 5 , in this embodiment, the backlash-free gear transmission multifunctional limiter includes: a seat plate assembly 1, the upper end of the gear assembly 8 is fixedly installed on the seat plate assembly 1, and the gear of the gear assembly 8 and the worm gear assembly 7 passes through the bearing 9 Coaxially connected; gear assembly two 12. The gears of the first gear assembly 8 and the second gear assembly 12 are metal gears with soft materials attached to their surfaces. The soft material includes: polymer materials, such as plastic, rubber, etc.; composite materials, such as: carbon fiber, polyethylene fiber, etc.; or other materials with similar properties.

[0030] Working process: the multi-functional limiter includes the seat plate assembly 1 which acts as an upper support, the upper part of the shaft assembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com