Gapless gear transmission multifunctional limiter

A gear transmission, multi-functional technology, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve problems such as potential safety hazards, and achieve the effects of low cost, reduced risk, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

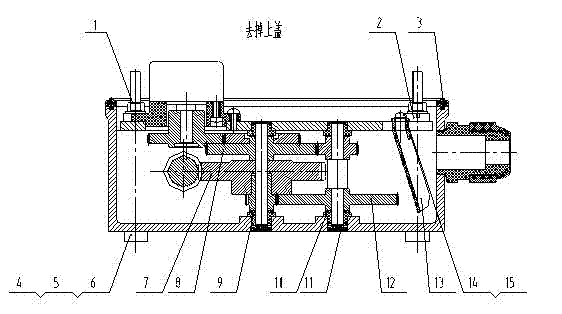

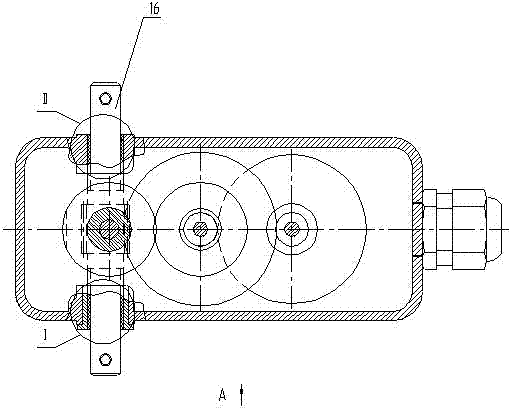

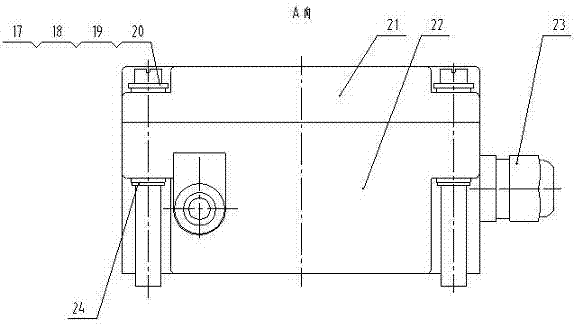

[0028] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0029] refer to Figures 1 to 5 , in this embodiment, the multi-function limiter of the backlash-free gear transmission includes: a seat plate assembly 1, the upper end of the gear assembly one 8 is fixedly mounted on the seat plate assembly 1, the gear assembly one 8 and the gear of the worm gear assembly 7 pass through the bearing 9 Coaxially connected; gear assembly two 12. The gears of the first gear assembly 8 and the second gear assembly 12 are metal gears with soft materials attached to their surfaces. The soft materials include: polymer materials, such as plastic, rubber, etc.; composite materials, such as carbon fiber, polyethylene fiber, etc.; or other materials with similar properties.

[0030] Workflow: The multi-function limiter includes a seat plate assembly 1 that supports the upper part, a gear assembly 8 is connected to it at the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com