Compact shelving moving device

A mobile device and compact shelf technology, which is applied to transmission devices, transmission device parts, cabinets for storing books, etc., can solve the problems of particularly high installation accuracy requirements, increased power consumption, and large processing axial deformation, and achieve good power. Transmission characteristics and transmission performance, the effect of improving stability and reliability, improving transmission performance and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

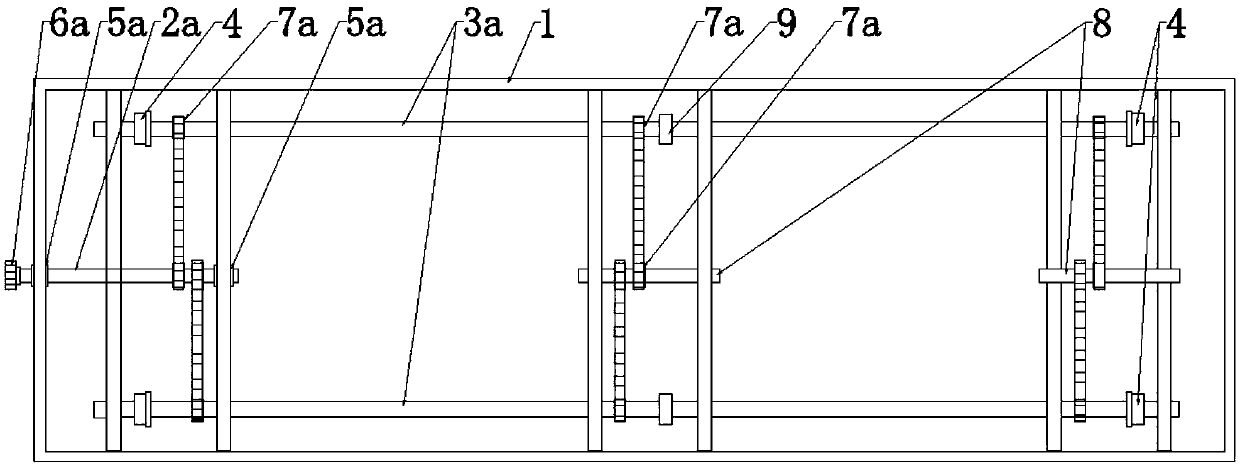

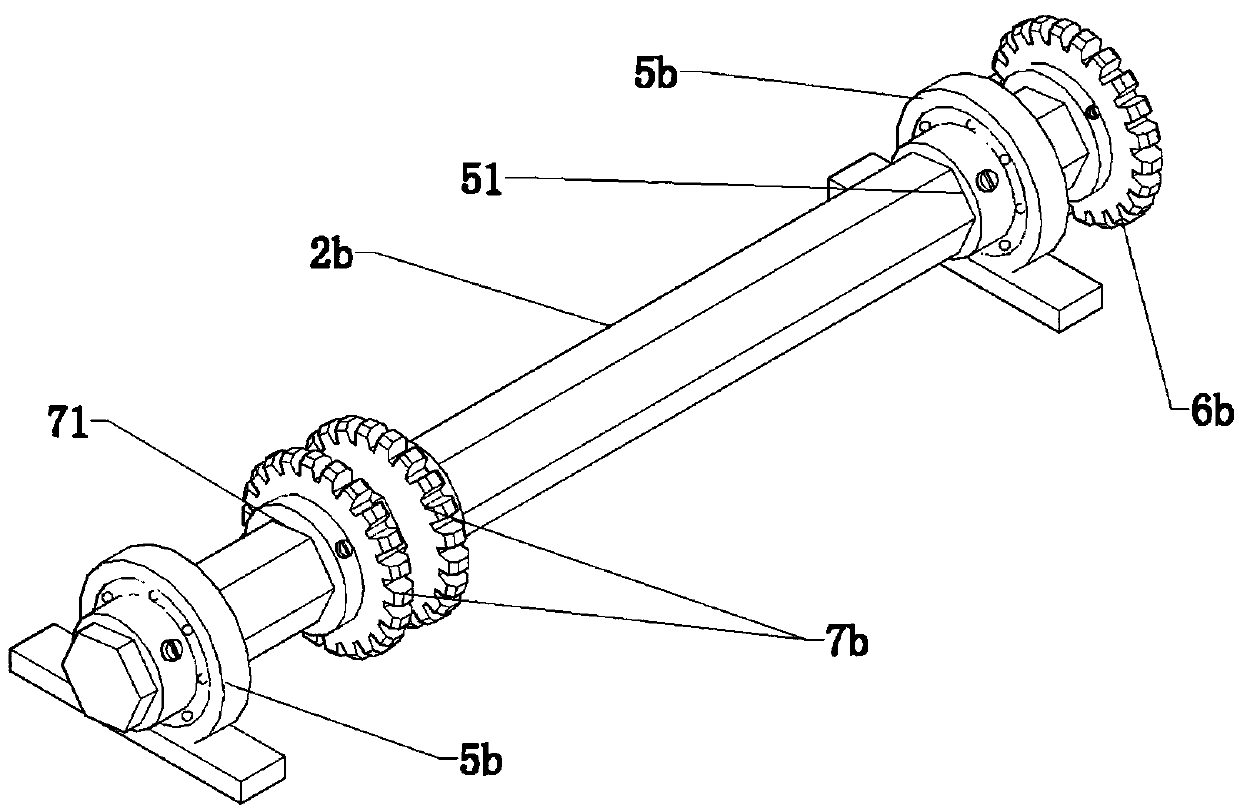

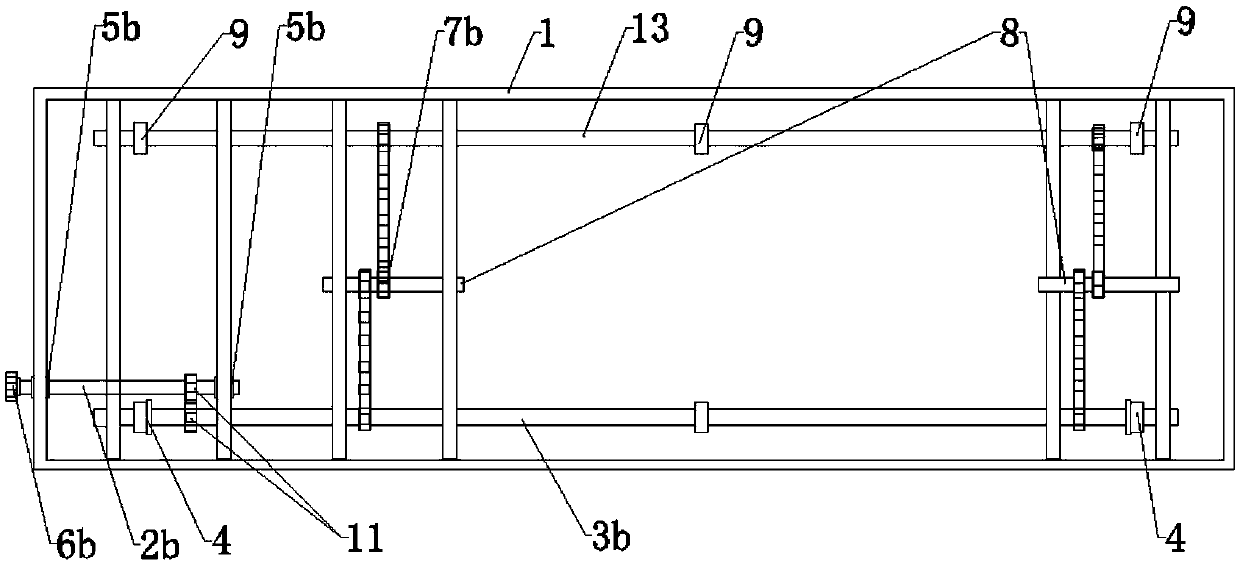

[0013] In order to further understand the technical solutions of the present invention, the present invention will be further described by the following embodiments in conjunction with the accompanying drawings.

[0014] The mobile device of the compact shelf of the present invention uses the transmission structure of the short driving shaft and the long driven shaft, that is, uses the transmission mode of the short driving shaft and the long driven shaft to carry out the walking transmission of the compact shelf bookshelf.

[0015] Simultaneously, in the present invention, the polygonal short or long driving shaft with a polygonal cross-sectional shape is arranged on the corresponding chassis through the polygonal short or long driving shaft whose cross-sectional shape is matched with the inner hole; the polygonal short driving shaft can also be Through the corresponding polygonal inner hole sprocket or meshing gear and its long or short driven shaft drive connection; at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com