Motor equipped with reducer and method of manufacturing the same

A technology with a reducer and a reducer, applied in the direction of controlling mechanical energy, electrical components, electromechanical devices, etc., can solve the problems of reduced coaxial performance and complicated connecting shafts, and achieve the effect of improving meshing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

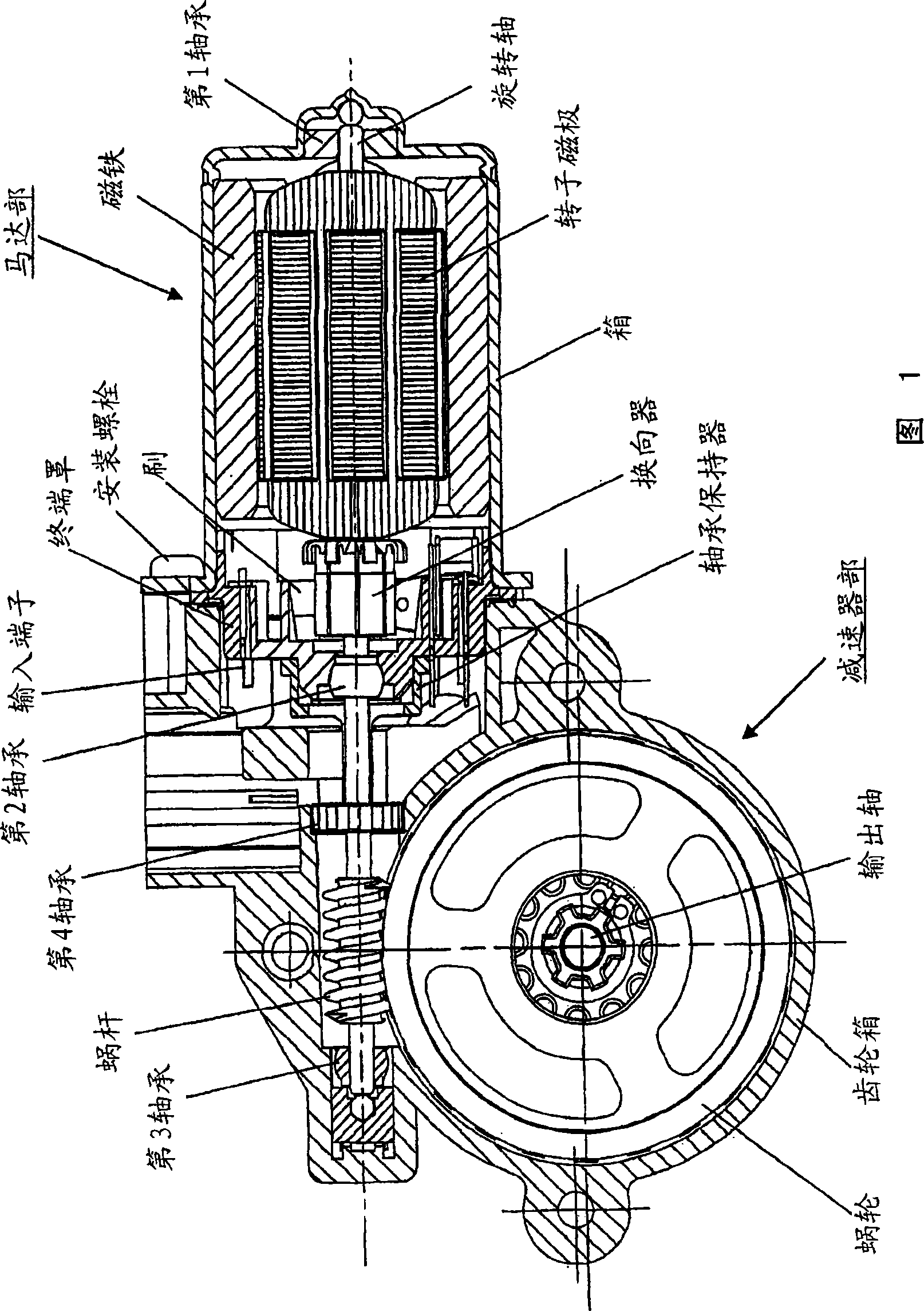

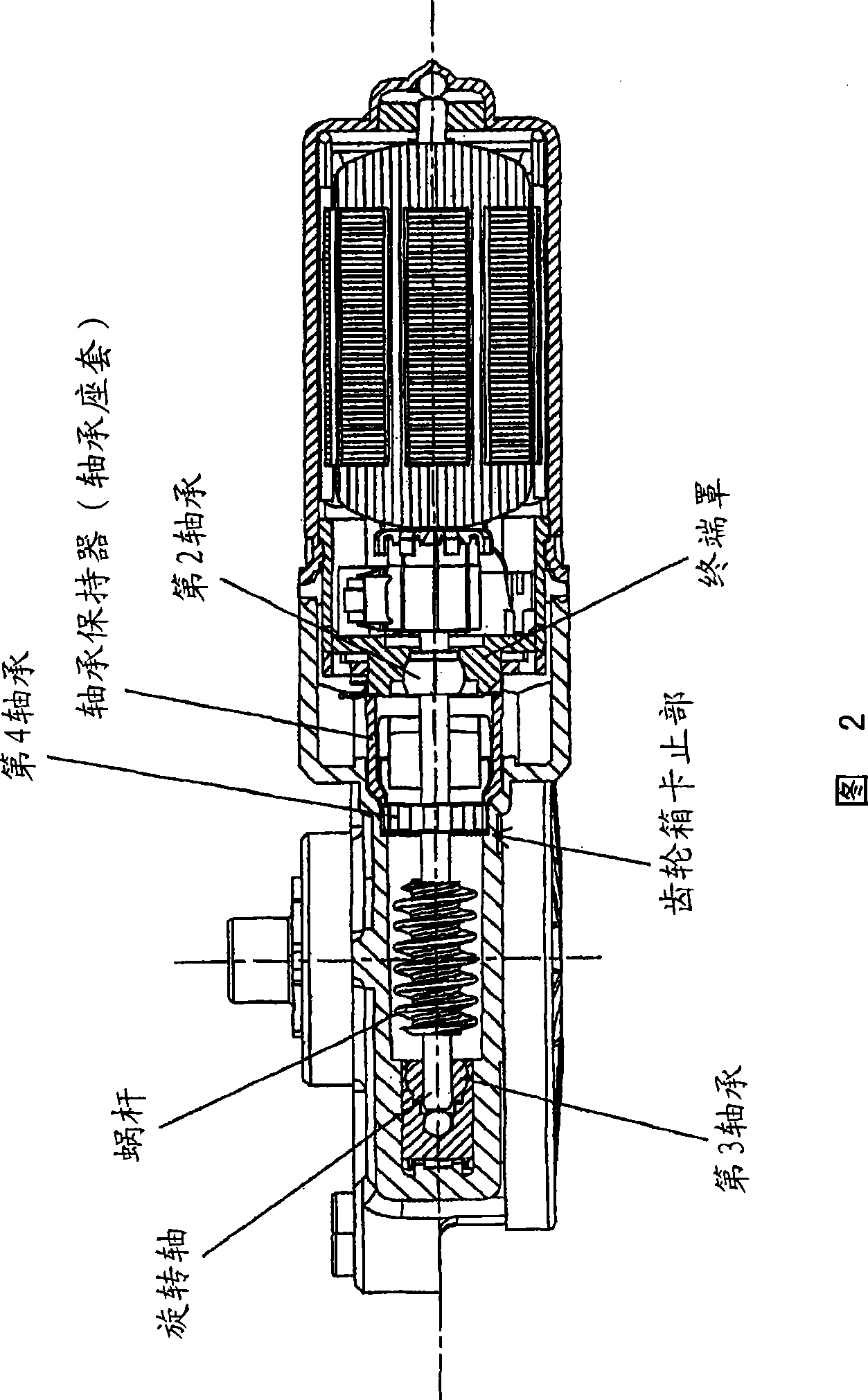

[0036] Fig. 2 is a cross-sectional view viewed from above in Fig. 1 , showing a fourth bearing and its vicinity, which is a feature of the present invention. As shown in the figure, the fourth bearing for supporting the rotating shaft is installed in the gearbox between the second bearing and the worm housed in the center of the end cover.

[0037] In the first embodiment, the fourth bearing is fixed by using the bearing sleeve as a bearing holder. After the fourth bearing is inserted into the rotating shaft, it is sandwiched and fixed between the locking portion of the gear case and the bearing sleeve from both sides. The locking portion of the gear case may be formed by a step or a protrusion integrally formed on the resin gear case.

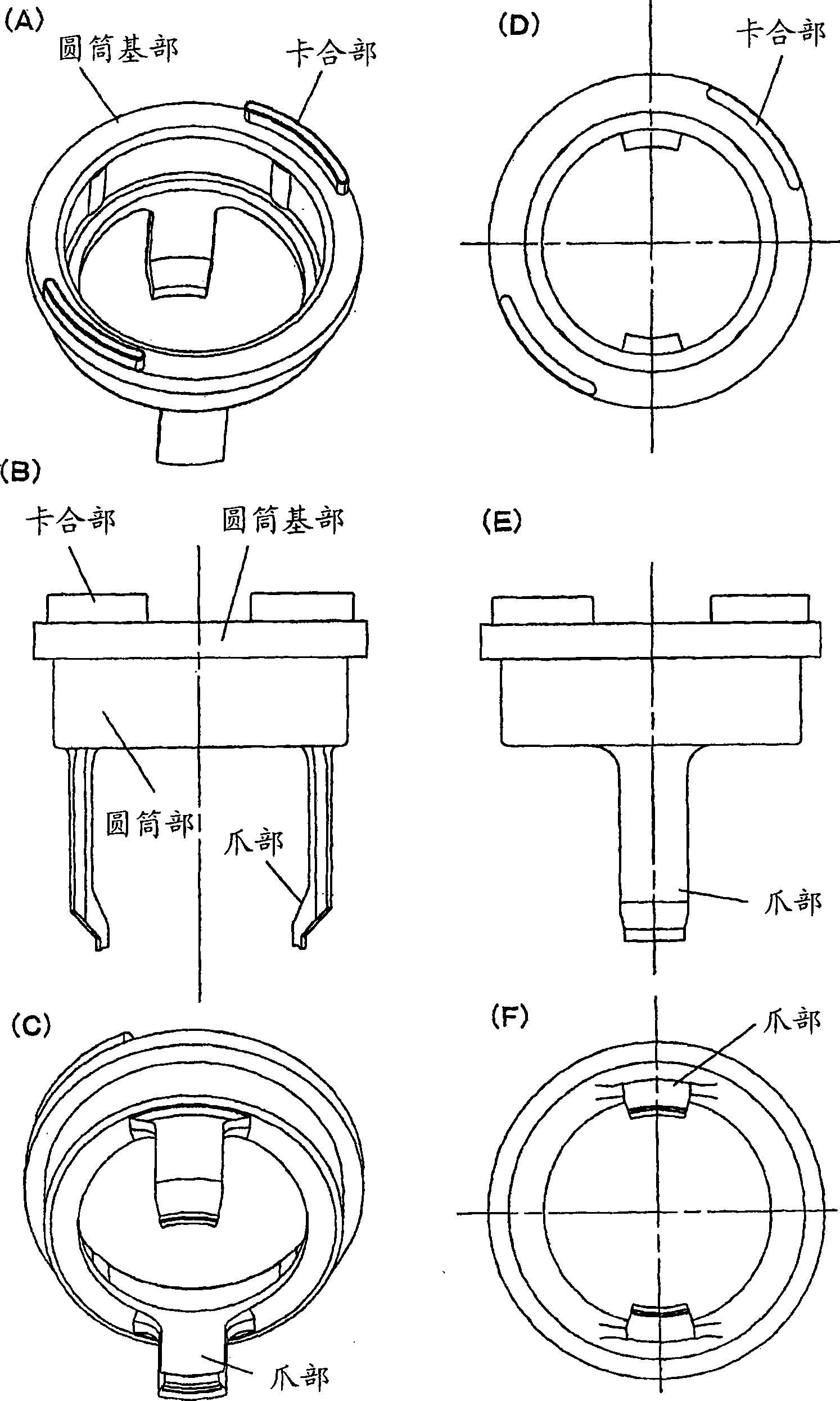

[0038] image 3is a diagram showing the bearing housing supporting the 4th bearing alone, image 3 (A)~ image 3 (F) is a figure which changed only the viewing direction of the same bearing sleeve. As shown in the figure, the bearing hous...

no. 2 Embodiment approach

[0046] In the second embodiment, the fourth bearing is fixed using the terminal holder as the bearing holder. Figure 7 It is a figure explaining the terminal holder. Figure 7 (A) is a view viewed from the outside (front side) of the motor unit, Figure 7 (B) is a figure seen from the inside (back side) of a motor part. Like the bearing housing of the first embodiment, this terminal holder not only has the function of supporting the fourth bearing, but also has a conductive member that guides the motor input terminal to a position suitable for connecting to an external lead, and can be installed with an electrical composed of components. Electrical components such as choke coils and capacitors for the purpose of noise cancellation can be mounted on this terminal holder.

[0047] On the front side of the terminal holder integrally formed of resin, the two claws integrally formed with resin on the left and right sides of the center hole for fitting the bearing holding part a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com