Non-standard toothed chain processing method and non-standard toothed chain

A processing method and tooth marking technology are applied in the direction of metal chains, metal material coating technology, solid-state diffusion coating, etc., which can solve the problems of low meshing accuracy of toothed chains, loud noises of toothed chains, and poor fatigue resistance. Achieve the effect of improving meshing accuracy, improving strength and good fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

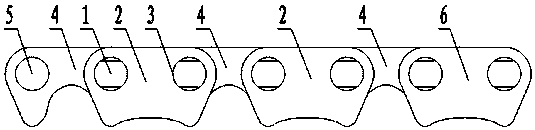

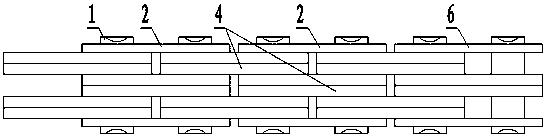

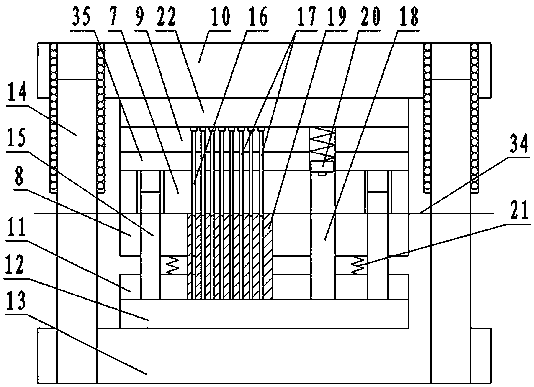

[0028] Example. Non-standard tooth chain processing methods, such as figure 1 , 2 , 3, and 4, including the following steps,

[0029] a. Punching, using a progressive die to carry out precision blanking on multiple chain plates 4 at the same time, so that the chain plate holes 5 and the sides of the chain plates 4 are all 100% bright, and the A product is obtained;

[0030] b. Carry out isothermal quenching treatment to product A, so that the hardness of chain plate 4 reaches 50-54HRC, and product B is obtained;

[0031] c. Carry out carbonitriding treatment on the guide plate 2, so that the hardness of the guide plate 2 reaches 45-50HRC, and obtain product C;

[0032] d. Carry out compound heat treatment of carbonitriding and isothermal quenching on the pin shaft 1, and finally carry out cryogenic treatment, so that the ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com