Compound spider piece used for single-screw compressor

A single-screw compressor and star wheel technology, applied in the field of star wheels, can solve the problems of affecting the meshing life of screw star wheels, high price, easy wear of star wheels, etc., to improve the meshing accuracy and the service life of the host, The effect of reducing production cost and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

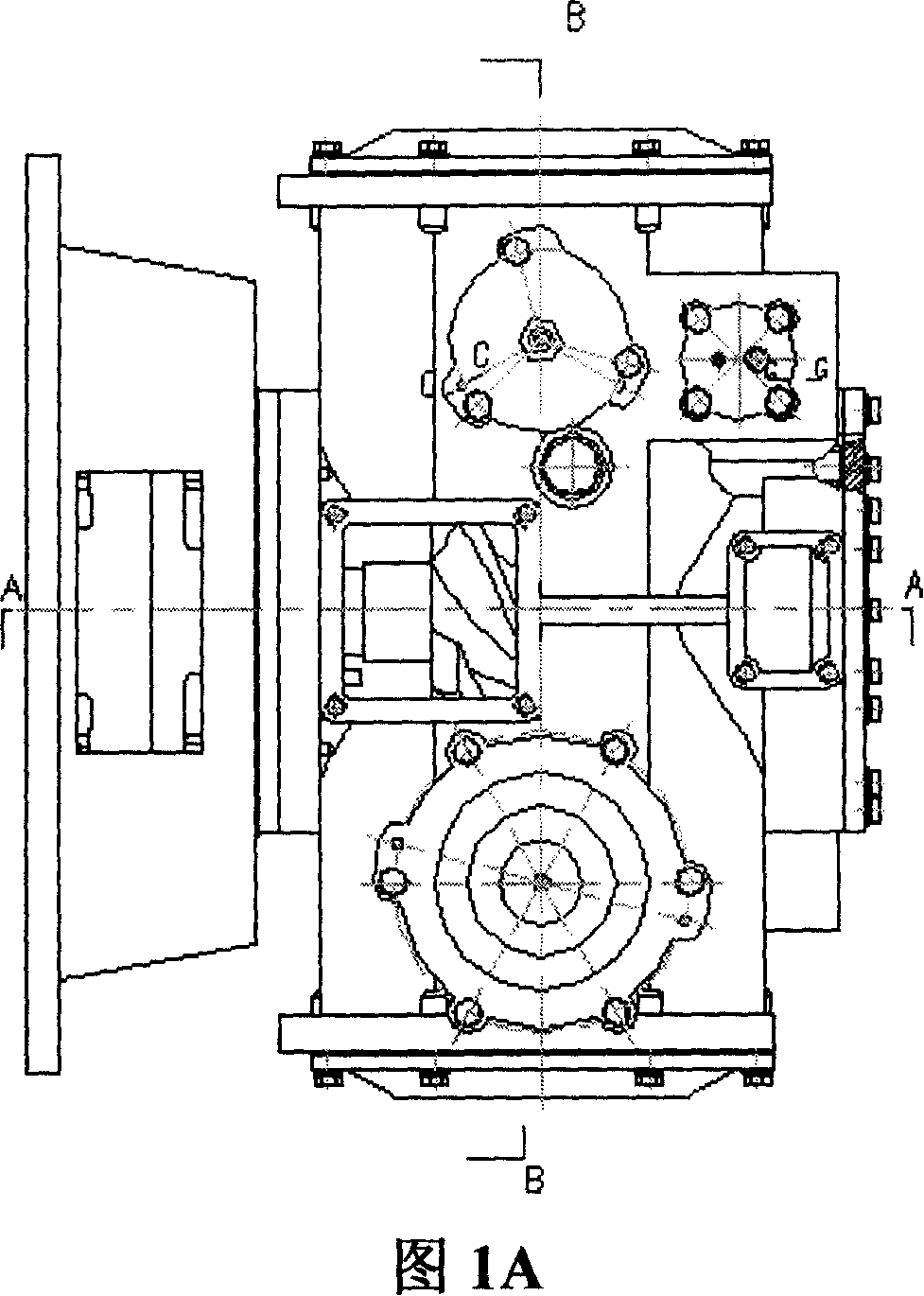

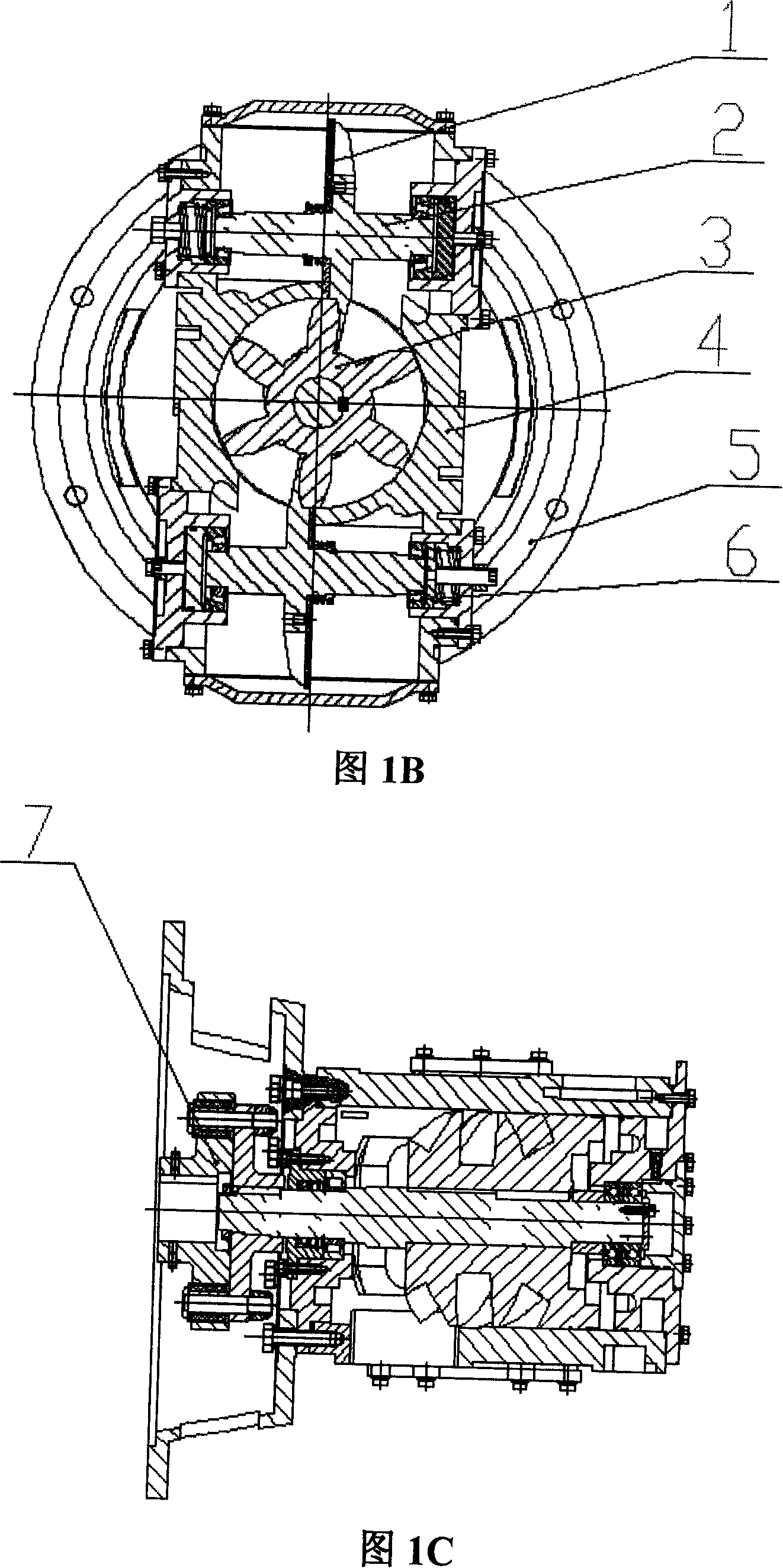

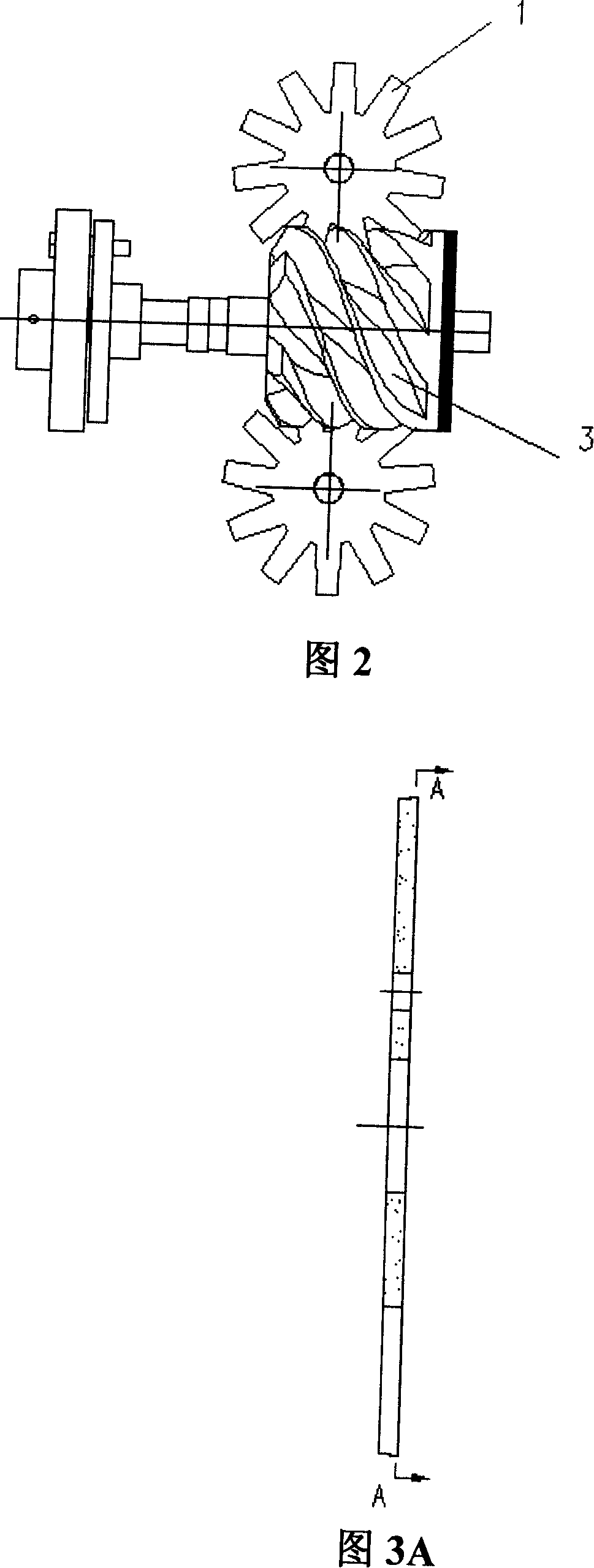

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0024] It can be seen from Fig. 4A, Fig. 4B, and Fig. 4C that the present invention includes: the inner layer is an alloy steel core plate 200, and the outer layer is a PEEK carbon fiber polymer 300; the PEEK carbon fiber polymer 300 is covered on the alloy steel core plate 200, and firmly bond with it.

[0025] According to the meshing surface of the star wheel and the screw, the present invention designs and manufactures a steel core plate, heat-treats the core plate to increase its rigidity, and makes a corresponding meshing surface, and molds a layer of PEEK carbon fiber polymer on the outside of the core plate. The core plate must be preheated, and the temperature should be as close as possible to the crystallization temperature of PEEK carbon fiber polymer. Qualitative treatment is carried out after fabrication and shaping. The qualitativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com